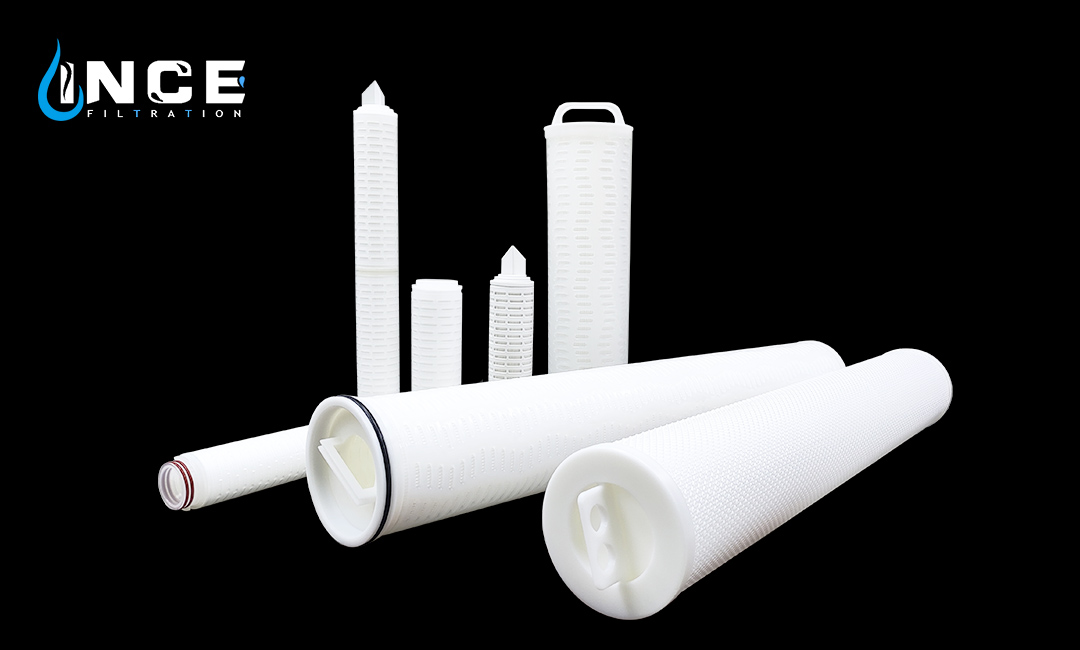

High Flow Filter Cartridges: A Comprehensive Guide for Industrial Use

Benefits of Using High Flow Filter Cartridges in Industrial Applications

High flow filter cartridges are an essential component in many industrial applications, providing a cost-effective and efficient solution for removing contaminants from liquids. These filter cartridges offer numerous benefits that make them a popular choice for industries such as oil and gas, food and beverage, pharmaceuticals, and more.

One of the key benefits of using high flow filter cartridges is their ability to handle a large volume of liquid flow. These cartridges are designed to accommodate high flow rates, making them ideal for applications where a large amount of liquid needs to be filtered quickly and efficiently. This can help improve productivity and reduce downtime, as the filters can process more liquid in a shorter amount of time.

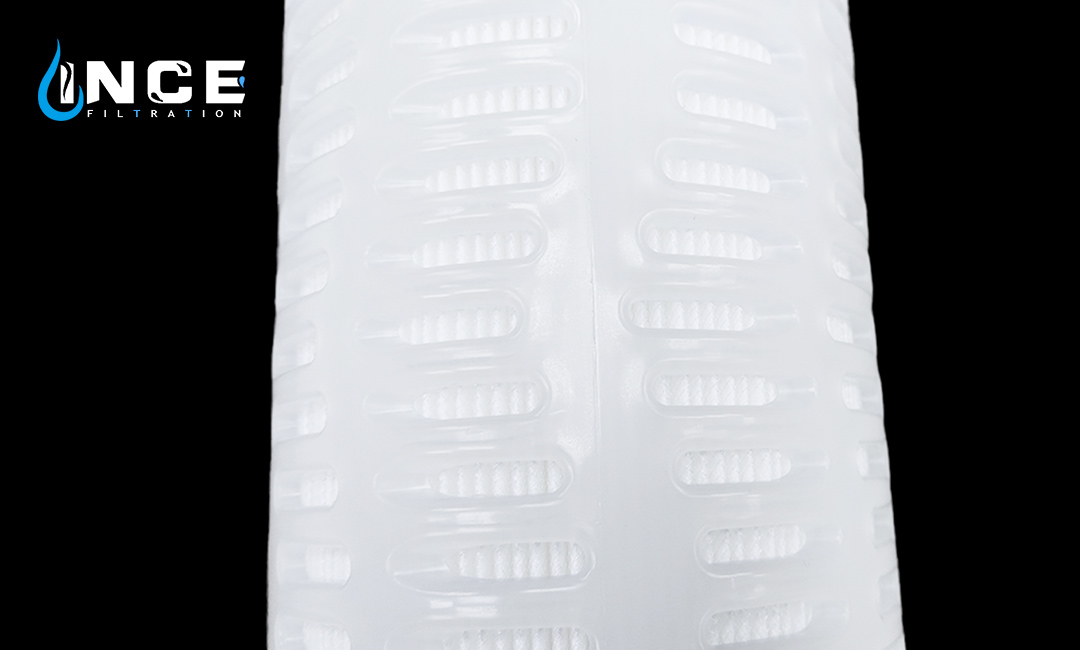

In addition to their high flow capacity, high flow filter cartridges also offer excellent filtration efficiency. These cartridges are designed to remove a wide range of contaminants, including particles, bacteria, and other impurities, ensuring that the filtered liquid meets the required quality standards. This can help prevent equipment damage, improve product quality, and ensure compliance with industry regulations.

Another benefit of using high flow filter cartridges is their long service life. These cartridges are constructed from durable materials that can withstand high flow rates and harsh operating conditions, allowing them to last longer than traditional filters. This can help reduce maintenance costs and downtime, as the filters will need to be replaced less frequently.

Furthermore, high flow filter cartridges are easy to install and replace, making them a convenient option for industrial applications. These cartridges can be quickly and easily installed in existing filtration systems, allowing for seamless integration into the production process. Additionally, when it comes time to replace the filters, the process is simple and straightforward, minimizing downtime and ensuring that production can continue uninterrupted.

In conclusion, high flow filter cartridges offer a range of benefits that make them an excellent choice for industrial applications. From their high flow capacity and filtration efficiency to their long service life and ease of installation, these cartridges provide a cost-effective and efficient solution for removing contaminants from liquids. Whether you work in the oil and gas, food and beverage, pharmaceutical, or another industry, high flow filter cartridges can help improve productivity, product quality, and regulatory compliance. Consider incorporating these filters into your filtration system to experience the many benefits they have to offer.

How to Choose the Right High Flow Filter Cartridge for Your Industrial Needs

High flow filter cartridges are essential components in industrial processes that require the filtration of large volumes of liquid. These cartridges are designed to handle high flow rates while effectively removing contaminants from the liquid stream. Choosing the right high flow filter cartridge for your industrial needs is crucial to ensure optimal performance and efficiency. In this comprehensive guide, we will discuss the key factors to consider when selecting a high flow filter cartridge for your specific application.

One of the first things to consider when choosing a high flow filter cartridge is the type of contaminants that need to be removed from the liquid stream. Different filter media are designed to target specific types of contaminants, such as sediment, particles, bacteria, or chemicals. Understanding the nature of the contaminants in your liquid stream will help you select the most appropriate filter media for your application.

Another important factor to consider is the flow rate of your industrial process. High flow filter cartridges are designed to handle a wide range of flow rates, so it is essential to choose a cartridge that can accommodate the flow rate of your specific application. Selecting a cartridge with the appropriate flow rate capacity will ensure that the filtration process is efficient and effective.

The size and dimensions of the high flow filter cartridge are also important considerations. The cartridge must fit properly within your filtration system to ensure optimal performance. It is essential to choose a cartridge that is compatible with your existing filtration equipment and can be easily installed and replaced as needed.

In addition to the type of contaminants, flow rate, and size, the micron rating of the high flow filter cartridge is another critical factor to consider. The micron rating indicates the size of particles that the filter can effectively remove from the liquid stream. Choosing a filter cartridge with the appropriate micron rating for your application will ensure that the filtration process is thorough and effective.

When selecting a high flow filter cartridge, it is also important to consider the material of construction. Filter cartridges are available in a variety of materials, including polypropylene, polyester, and fiberglass. The material of construction will impact the durability and compatibility of the cartridge with different types of liquids and chemicals. It is essential to choose a cartridge made from a material that is suitable for your specific application.

Finally, it is important to consider the cost and availability of high flow filter cartridges. Different manufacturers offer a range of filter cartridges at varying price points. It is essential to choose a cartridge that fits within your budget while still meeting the requirements of your industrial process. Additionally, it is important to consider the availability of replacement cartridges to ensure that you can easily maintain and replace your filtration system as needed.

In conclusion, choosing the right high flow filter cartridge for your industrial needs requires careful consideration of several key factors, including the type of contaminants, flow rate, size, micron rating, material of construction, and cost. By taking these factors into account, you can select a high flow filter cartridge that will effectively remove contaminants from your liquid stream and ensure the efficiency and performance of your industrial process.

Maintenance Tips for High Flow Filter Cartridges in Industrial Settings

High flow filter cartridges are essential components in industrial settings, where they play a crucial role in maintaining the quality of air and liquids used in various processes. These filter cartridges are designed to handle high flow rates and remove contaminants efficiently, making them ideal for use in industries such as manufacturing, food and beverage, pharmaceuticals, and more.

To ensure the optimal performance of high flow filter cartridges, regular maintenance is essential. Proper maintenance not only extends the lifespan of the filter cartridges but also ensures that they continue to operate at peak efficiency. In this article, we will discuss some important maintenance tips for high flow filter cartridges in industrial settings.

One of the most important maintenance tasks for high flow filter cartridges is regular inspection. Inspecting the cartridges on a regular basis allows you to identify any signs of wear or damage early on, preventing potential issues from escalating. During the inspection, check for any visible signs of damage, such as tears or holes in the filter media, as well as any signs of clogging or blockages.

In addition to visual inspection, it is also important to monitor the pressure drop across the filter cartridges. A sudden increase in pressure drop can indicate that the cartridges are becoming clogged and may need to be replaced. Monitoring the pressure drop regularly allows you to take proactive measures to prevent any disruptions to your industrial processes.

Another important maintenance tip for high flow filter cartridges is to follow the manufacturer’s recommended replacement schedule. Over time, filter cartridges will become less effective at removing contaminants, even with regular cleaning and maintenance. By replacing the cartridges according to the manufacturer’s recommendations, you can ensure that your filtration system continues to operate at peak efficiency.

When replacing high flow filter cartridges, it is important to use the correct replacement cartridges specified by the manufacturer. Using the wrong type of cartridges can lead to reduced filtration efficiency and potentially damage to your industrial equipment. Always refer to the manufacturer’s guidelines when selecting replacement cartridges to ensure compatibility and optimal performance.

Proper cleaning of high flow filter cartridges is also essential for maintaining their efficiency. Depending on the type of contaminants being filtered, the cartridges may need to be cleaned periodically to remove any buildup. Follow the manufacturer’s guidelines for cleaning procedures, and use the appropriate cleaning solutions to avoid damaging the filter media.

In conclusion, proper maintenance of high flow filter cartridges is essential for ensuring the continued efficiency and effectiveness of your industrial filtration system. Regular inspection, monitoring of pressure drop, following the manufacturer’s replacement schedule, using the correct replacement cartridges, and proper cleaning are all important maintenance tasks that should be performed regularly. By taking proactive measures to maintain your filter cartridges, you can ensure that your industrial processes run smoothly and efficiently.

Case Studies: Successful Implementation of High Flow Filter Cartridges in Industrial Processes

High flow filter cartridges have become an essential component in industrial processes, providing efficient filtration solutions for a wide range of applications. In this article, we will explore some case studies that demonstrate the successful implementation of high flow filter cartridges in various industrial settings.

One such case study involves a manufacturing plant that produces chemicals for the automotive industry. The plant was facing challenges with its existing filtration system, which was unable to handle the high flow rates required for the production process. After consulting with filtration experts, the plant decided to switch to high flow filter cartridges.

The high flow filter cartridges were able to handle the increased flow rates without compromising on filtration efficiency. This resulted in improved product quality and reduced downtime due to filter changes. The plant saw a significant increase in productivity and cost savings as a result of implementing high flow filter cartridges.

Another case study involves a food processing facility that was struggling with frequent filter changes and clogging issues. The facility was using standard filter cartridges, which were unable to cope with the high flow rates and large volumes of particulate matter in the processing line. After switching to high flow filter cartridges, the facility saw a dramatic improvement in filtration performance.

The high flow filter cartridges were able to handle the large volumes of particulate matter without clogging, resulting in reduced downtime and maintenance costs. The facility also saw an improvement in product quality, as the high flow filter cartridges were able to remove more contaminants from the processing line. Overall, the implementation of high flow filter cartridges led to increased efficiency and cost savings for the food processing facility.

In a third case study, a power plant was facing challenges with its cooling water system, which was prone to fouling and corrosion. The plant was using standard filter cartridges, which were unable to provide adequate filtration for the cooling water system. After consulting with filtration experts, the plant decided to switch to high flow filter cartridges.

The high flow filter cartridges were able to provide superior filtration for the cooling water system, removing contaminants and preventing fouling and corrosion. This resulted in improved efficiency and reduced maintenance costs for the power plant. The plant also saw a decrease in downtime and an increase in equipment lifespan as a result of implementing high flow filter cartridges.

These case studies demonstrate the versatility and effectiveness of high flow filter cartridges in industrial processes. Whether it is in chemical manufacturing, food processing, or power generation, high flow filter cartridges have proven to be a reliable and cost-effective solution for improving filtration performance.

In conclusion, high flow filter cartridges are a valuable tool for industrial processes, providing efficient filtration solutions for a wide range of applications. By implementing high flow filter cartridges, businesses can improve productivity, reduce downtime, and save on maintenance costs. If you are looking to enhance your filtration system, consider switching to high flow filter cartridges for optimal performance and cost savings.