High Flow Filter Cartridges vs. Standard Filters: Key Differences

Efficiency

High flow filter cartridges and standard filters are both essential components in various industrial processes, but they differ significantly in terms of efficiency. Understanding these key differences can help businesses make informed decisions when selecting the right filtration system for their specific needs.

One of the primary differences between high flow filter cartridges and standard filters is their flow rate capabilities. High flow filter cartridges are designed to handle a much higher flow rate compared to standard filters. This means that they can process a larger volume of fluid in a shorter amount of time, making them ideal for applications where high flow rates are required.

In contrast, standard filters are typically limited in their flow rate capacity, which can result in slower processing times and reduced efficiency. This can be a significant drawback in industries where time is of the essence, such as in manufacturing or wastewater treatment plants.

Another key difference between high flow filter cartridges and standard filters is their filtration efficiency. High flow filter cartridges are specifically engineered to provide superior filtration performance, removing a higher percentage of contaminants from the fluid being processed. This can result in cleaner, higher quality output and reduced maintenance costs in the long run.

On the other hand, standard filters may not be as effective in capturing smaller particles or contaminants, leading to lower filtration efficiency and potentially compromising the quality of the end product. This can be a critical issue in industries where product quality is paramount, such as in pharmaceutical manufacturing or food and beverage production.

In addition to flow rate and filtration efficiency, high flow filter cartridges also offer advantages in terms of cost-effectiveness. While high flow filter cartridges may have a higher upfront cost compared to standard filters, their superior performance and longer lifespan can result in significant cost savings over time. This is especially true in industries with high filtration demands, where the efficiency and durability of high flow filter cartridges can lead to reduced downtime and maintenance costs.

Standard filters, on the other hand, may require more frequent replacements and maintenance, which can add up in terms of overall operating costs. While standard filters may be more budget-friendly initially, businesses should consider the long-term cost implications of using standard filters versus high flow filter cartridges.

In conclusion, high flow filter cartridges and standard filters differ significantly in terms of efficiency, flow rate capabilities, filtration performance, and cost-effectiveness. Businesses should carefully evaluate their specific filtration needs and requirements to determine which type of filter is best suited for their operations. While standard filters may be sufficient for some applications, high flow filter cartridges offer superior performance and long-term cost savings, making them a preferred choice for industries with high filtration demands. By understanding these key differences, businesses can make informed decisions when selecting the right filtration system for their operations.

Flow Rate

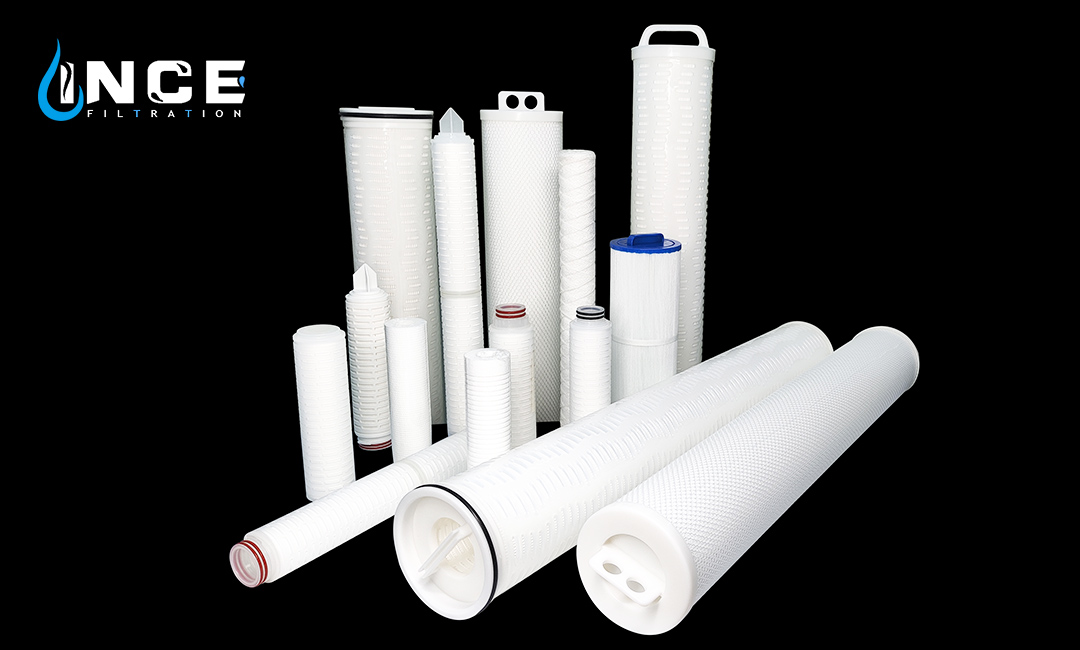

High flow filter cartridges and standard filters are two common types of filtration systems used in various industries to remove impurities from liquids or gases. One key difference between these two types of filters is their flow rate capabilities. High flow filter cartridges are designed to handle a higher flow rate compared to standard filters, making them ideal for applications where a large volume of fluid needs to be filtered quickly and efficiently.

High flow filter cartridges are typically used in industrial settings where there is a need to process large quantities of liquid or gas in a short amount of time. These filters are designed with a larger surface area and a higher dirt-holding capacity, allowing them to handle a higher flow rate without compromising on filtration efficiency. This makes high flow filter cartridges a cost-effective solution for applications that require high throughput and minimal downtime.

On the other hand, standard filters are designed for applications where the flow rate is not a critical factor. These filters are commonly used in residential and commercial settings, as well as in smaller-scale industrial applications where the volume of fluid to be filtered is relatively low. Standard filters are typically smaller in size and have a lower dirt-holding capacity compared to high flow filter cartridges, which limits their ability to handle high flow rates.

When it comes to choosing between high flow filter cartridges and standard filters, the flow rate requirements of the application play a crucial role. If you need to filter a large volume of fluid quickly, a high flow filter cartridge would be the ideal choice. These filters can handle flow rates of up to 500 gallons per minute or more, depending on the specific model and design. In contrast, standard filters are typically limited to flow rates of 10-50 gallons per minute, making them unsuitable for high-volume applications.

In addition to their flow rate capabilities, high flow filter cartridges and standard filters also differ in terms of their maintenance requirements. High flow filter cartridges are designed to be more durable and long-lasting compared to standard filters, which means they require less frequent replacement and maintenance. This can result in cost savings over time, especially in applications where filters need to be replaced frequently due to high flow rates.

Furthermore, high flow filter cartridges are often easier to install and replace compared to standard filters, thanks to their larger size and design. This can help reduce downtime and improve overall efficiency in applications where filter replacement is a regular occurrence. Standard filters, on the other hand, may require more frequent maintenance and replacement due to their smaller size and lower dirt-holding capacity, which can increase operating costs and downtime.

In conclusion, high flow filter cartridges and standard filters differ significantly in terms of their flow rate capabilities and maintenance requirements. High flow filter cartridges are designed to handle high flow rates efficiently, making them ideal for applications that require fast and effective filtration of large volumes of fluid. Standard filters, on the other hand, are better suited for applications where the flow rate is not a critical factor and where maintenance requirements are minimal. By understanding the key differences between these two types of filters, you can choose the right filtration system for your specific application and ensure optimal performance and efficiency.

Pressure Drop

High Flow Filter Cartridges vs. Standard Filters: Key Differences

When it comes to filtration systems, one of the key factors to consider is the pressure drop. Pressure drop refers to the decrease in pressure that occurs as a fluid passes through a filter. In the case of high flow filter cartridges and standard filters, there are significant differences in how they handle pressure drop.

High flow filter cartridges are designed to handle a higher flow rate than standard filters. This means that they can process a larger volume of fluid in a shorter amount of time. As a result, high flow filter cartridges typically have a lower pressure drop compared to standard filters. This is because the larger surface area of the filter allows for a more efficient filtration process, reducing the resistance to flow and minimizing pressure drop.

On the other hand, standard filters are designed for lower flow rates and may not be able to handle the same volume of fluid as high flow filter cartridges. As a result, standard filters may experience a higher pressure drop due to the smaller surface area available for filtration. This can lead to increased energy consumption and reduced efficiency in the filtration process.

In addition to the differences in pressure drop, high flow filter cartridges and standard filters also vary in terms of their maintenance requirements. High flow filter cartridges typically have a longer lifespan and require less frequent replacement compared to standard filters. This is because the larger surface area of the filter allows for more particles to be captured before the filter becomes clogged. As a result, high flow filter cartridges can provide more consistent filtration performance over time.

Standard filters, on the other hand, may need to be replaced more frequently due to their smaller surface area and lower capacity for capturing particles. This can result in higher maintenance costs and downtime for the filtration system. Additionally, standard filters may be more prone to clogging, which can further increase pressure drop and reduce the efficiency of the filtration process.

In conclusion, the key differences between high flow filter cartridges and standard filters lie in their handling of pressure drop and maintenance requirements. High flow filter cartridges are designed to handle higher flow rates and have a lower pressure drop compared to standard filters. They also have a longer lifespan and require less frequent replacement, making them a more cost-effective and efficient option for filtration systems.

On the other hand, standard filters may experience a higher pressure drop due to their smaller surface area and lower capacity for capturing particles. They may also require more frequent replacement and maintenance, leading to higher costs and reduced efficiency in the filtration process. Ultimately, the choice between high flow filter cartridges and standard filters will depend on the specific needs and requirements of the filtration system in question.

Cost Effectiveness

High Flow Filter Cartridges vs. Standard Filters: Key Differences

When it comes to choosing the right filtration system for your industrial or commercial needs, there are several factors to consider. One of the key decisions you will need to make is whether to use high flow filter cartridges or standard filters. Both options have their own set of advantages and disadvantages, but understanding the key differences between the two can help you make an informed decision.

Cost effectiveness is a crucial factor to consider when choosing between high flow filter cartridges and standard filters. High flow filter cartridges are generally more expensive upfront compared to standard filters. However, high flow filter cartridges have a longer lifespan and require less frequent replacement, which can result in cost savings in the long run. Standard filters, on the other hand, are typically cheaper to purchase initially but may need to be replaced more frequently, leading to higher maintenance costs over time.

In terms of efficiency, high flow filter cartridges are designed to handle a higher flow rate compared to standard filters. This means that high flow filter cartridges can process a larger volume of fluid in a shorter amount of time, making them ideal for applications that require high flow rates. Standard filters, on the other hand, may struggle to keep up with high flow rates and may become clogged more easily, leading to decreased efficiency and potentially costly downtime.

Another key difference between high flow filter cartridges and standard filters is their filtration capacity. High flow filter cartridges are typically designed to remove larger particles and contaminants from fluids, making them suitable for applications where a high level of filtration is required. Standard filters, on the other hand, may not be able to capture as many particles or contaminants, leading to lower filtration efficiency.

When it comes to maintenance, high flow filter cartridges are generally easier to replace and require less frequent maintenance compared to standard filters. High flow filter cartridges are typically designed to be easily installed and removed, making them a convenient option for applications where downtime needs to be minimized. Standard filters, on the other hand, may require more frequent maintenance and replacement, which can be time-consuming and costly.

Overall, the choice between high flow filter cartridges and standard filters will depend on your specific needs and requirements. If you require a filtration system that can handle high flow rates, provide efficient filtration, and minimize maintenance costs, high flow filter cartridges may be the best option for you. However, if cost is a primary concern and you do not require high flow rates or advanced filtration capabilities, standard filters may be a more cost-effective choice.

In conclusion, high flow filter cartridges and standard filters each have their own set of advantages and disadvantages when it comes to cost effectiveness. Understanding the key differences between the two options can help you make an informed decision that meets your specific needs and requirements. Whether you choose high flow filter cartridges or standard filters, it is important to consider factors such as efficiency, filtration capacity, and maintenance requirements to ensure that you select the best filtration system for your application.