High Flow Filter Elements: Designed for Precision and Efficiency

High Flow Filter Elements: Key Features and Benefits

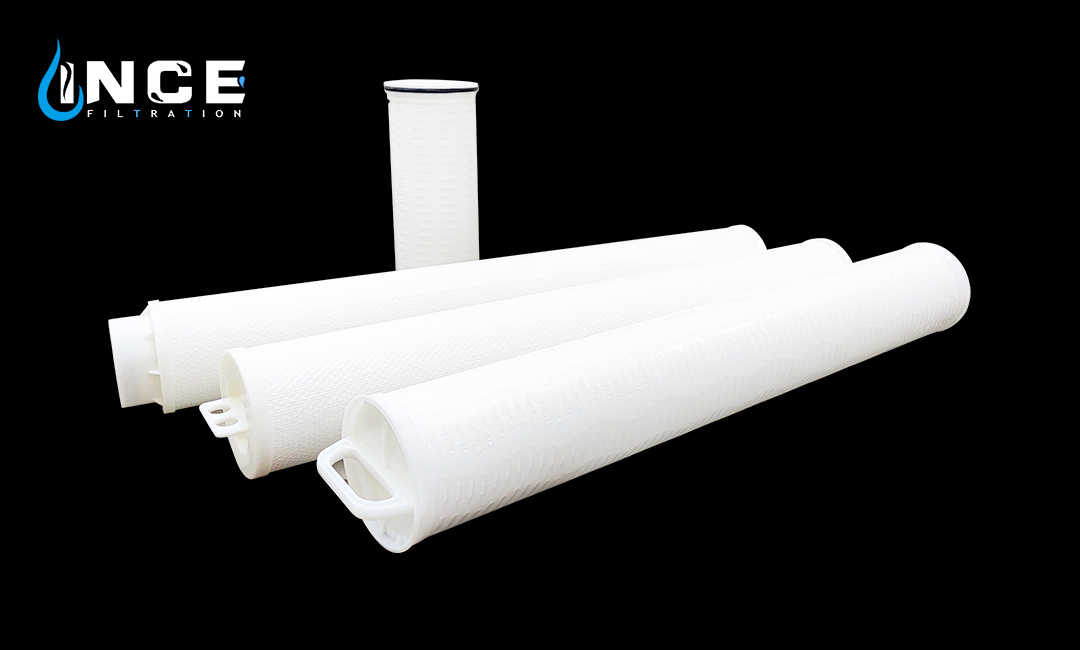

High flow filter elements are engineered to meet the demanding requirements of various industrial applications, providing a blend of precision and efficiency that is essential in today’s fast-paced environments. One of the most significant features of these filter elements is their ability to handle large volumes of fluid while maintaining optimal filtration performance. This capability is particularly crucial in sectors such as pharmaceuticals, food and beverage, and chemical processing, where the purity of the final product is paramount. By utilizing advanced materials and innovative designs, high flow filter elements ensure that contaminants are effectively removed, thereby safeguarding product integrity and compliance with stringent regulatory standards.

Another key feature of high flow filter elements is their enhanced surface area, which allows for greater dirt-holding capacity. This characteristic not only extends the service life of the filter but also reduces the frequency of replacements, leading to lower operational costs. The design of these filter elements often incorporates pleated configurations, which maximize the surface area without significantly increasing the overall size of the filter. As a result, users can benefit from longer intervals between maintenance and reduced downtime, which is critical for maintaining productivity in industrial settings.

Moreover, high flow filter elements are designed for easy installation and replacement, which further contributes to their efficiency. Many models feature standardized dimensions that allow for seamless integration into existing filtration systems. This compatibility minimizes the need for extensive modifications or additional equipment, making it easier for operators to upgrade their filtration capabilities without incurring significant costs. Additionally, the straightforward design of these elements facilitates quick change-outs, enabling facilities to maintain continuous operations with minimal disruption.

In terms of versatility, high flow filter elements can be tailored to meet specific application needs. They are available in various materials, such as polypropylene, stainless steel, and fiberglass, each offering unique benefits depending on the fluid being filtered and the operating conditions. For instance, polypropylene filters are often chosen for their chemical resistance and lightweight properties, making them ideal for aggressive fluids. Conversely, stainless steel filters provide durability and can withstand higher temperatures and pressures, making them suitable for more demanding applications. This adaptability ensures that users can select the most appropriate filter element for their specific requirements, enhancing overall system performance.

Furthermore, the efficiency of high flow filter elements is complemented by their ability to maintain low pressure drops across the filter media. This characteristic is essential for energy conservation, as it reduces the workload on pumps and other equipment in the filtration system. By minimizing pressure loss, these filter elements contribute to lower energy consumption, which not only reduces operational costs but also supports sustainability initiatives within organizations.

In conclusion, high flow filter elements represent a significant advancement in filtration technology, offering a combination of precision, efficiency, and versatility that is essential for modern industrial applications. Their ability to handle large volumes of fluid while maintaining high filtration performance, coupled with features such as enhanced surface area and easy installation, makes them an invaluable asset in various sectors. As industries continue to prioritize efficiency and compliance, the adoption of high flow filter elements will likely become increasingly prevalent, driving improvements in product quality and operational effectiveness.

Applications of High Flow Filter Elements in Various Industries

High flow filter elements play a crucial role in a variety of industries, providing essential filtration solutions that enhance operational efficiency and product quality. These filters are designed to handle large volumes of fluid while maintaining a high level of precision, making them indispensable in sectors such as pharmaceuticals, food and beverage, water treatment, and industrial manufacturing. In the pharmaceutical industry, for instance, high flow filter elements are employed to ensure the purity of products by removing contaminants from raw materials and final formulations. The stringent regulatory requirements necessitate the use of filters that can deliver consistent performance, and high flow filters meet these demands by providing reliable filtration without compromising flow rates.

Similarly, in the food and beverage sector, maintaining product integrity is paramount. High flow filter elements are utilized to eliminate particulates and microorganisms from liquids, ensuring that the final products are safe for consumption. The ability of these filters to operate efficiently under varying pressure conditions allows manufacturers to optimize their processes, reducing downtime and enhancing productivity. Furthermore, the use of high flow filters can lead to significant cost savings by minimizing waste and improving yield, which is particularly important in an industry where margins can be tight.

In the realm of water treatment, high flow filter elements are essential for both municipal and industrial applications. These filters are designed to handle large volumes of water, effectively removing sediments, algae, and other impurities that can compromise water quality. As water scarcity becomes an increasingly pressing issue, the demand for efficient filtration solutions has grown. High flow filters not only improve the quality of treated water but also contribute to the sustainability of water resources by enabling the recycling and reuse of water in various applications. This is particularly relevant in industries such as agriculture, where treated water can be used for irrigation, thus conserving freshwater supplies.

Moreover, in industrial manufacturing, high flow filter elements are critical for maintaining the cleanliness of process fluids. Whether in hydraulic systems, cooling towers, or lubrication systems, these filters help to protect equipment from damage caused by contaminants. By ensuring that only clean fluids circulate through machinery, high flow filters extend the lifespan of equipment and reduce maintenance costs. Additionally, the ability to filter large volumes of fluid quickly allows manufacturers to maintain high production rates without sacrificing quality.

Transitioning to the energy sector, high flow filter elements are increasingly being used in oil and gas applications. These filters are vital for separating particulates from crude oil and natural gas, ensuring that the extracted resources meet quality standards before refining. The efficiency of high flow filters in these applications not only enhances the quality of the final products but also minimizes the environmental impact by reducing the likelihood of spills and leaks.

In conclusion, the applications of high flow filter elements span a wide range of industries, each benefiting from the precision and efficiency these filters provide. As industries continue to evolve and face new challenges, the demand for advanced filtration solutions will only increase. High flow filter elements stand out as a key technology that not only meets current needs but also paves the way for future innovations in filtration and fluid management. By ensuring the purity and quality of products across various sectors, these filters play an integral role in promoting operational excellence and sustainability.

Comparing High Flow Filter Elements to Traditional Filters

High flow filter elements have emerged as a significant advancement in filtration technology, particularly when compared to traditional filters. The primary distinction between these two types of filtration systems lies in their design and operational efficiency. Traditional filters, often characterized by their smaller surface areas and lower flow rates, can struggle to meet the demands of modern industrial applications. In contrast, high flow filter elements are engineered to provide superior performance, allowing for higher flow rates while maintaining effective filtration.

One of the most notable advantages of high flow filter elements is their ability to handle larger volumes of fluid without compromising filtration quality. This is largely due to their innovative design, which typically features a larger surface area and a more open structure. As a result, these filters can accommodate higher flow rates, reducing the need for multiple filter units in a system. This not only streamlines the filtration process but also minimizes the overall footprint of the filtration system, making it a more efficient choice for facilities with space constraints.

Moreover, high flow filter elements are designed to operate effectively under varying pressure conditions. Traditional filters often experience a drop in performance as pressure increases, leading to potential clogging and reduced efficiency. In contrast, high flow filters maintain their performance even under high-pressure scenarios, ensuring consistent filtration and reducing the frequency of filter replacements. This reliability translates into lower operational costs and less downtime, which are critical factors for industries that rely on continuous processes.

In addition to their operational efficiency, high flow filter elements also offer enhanced precision in filtration. The materials used in their construction are often engineered to capture a wider range of particle sizes, from larger contaminants to microscopic impurities. This capability is particularly important in industries such as pharmaceuticals and food processing, where product purity is paramount. By ensuring that even the smallest particles are effectively removed, high flow filters contribute to the overall quality and safety of the end product.

Furthermore, the maintenance requirements for high flow filter elements are generally less demanding than those of traditional filters. With their extended service life and reduced frequency of replacement, these filters can significantly lower maintenance costs and labor efforts. This is particularly advantageous in large-scale operations where maintenance personnel may be stretched thin. The ease of maintenance associated with high flow filters allows for more efficient resource allocation, enabling companies to focus on core operations rather than routine upkeep.

Transitioning from traditional filters to high flow filter elements can also lead to improved environmental sustainability. By reducing the number of filters required and extending their service life, companies can decrease waste generation and lower their overall environmental footprint. This aligns with the growing emphasis on sustainability in industrial practices, as organizations seek to minimize their impact on the environment while maintaining operational efficiency.

In conclusion, the comparison between high flow filter elements and traditional filters reveals significant advantages in terms of efficiency, precision, and sustainability. As industries continue to evolve and demand more from their filtration systems, high flow filter elements stand out as a superior choice. Their ability to handle higher flow rates, maintain performance under pressure, and provide precise filtration makes them an essential component in modern filtration applications. As organizations strive for greater efficiency and sustainability, the adoption of high flow filter elements is likely to become increasingly prevalent, marking a pivotal shift in filtration technology.

Maintenance Tips for High Flow Filter Elements to Ensure Longevity

High flow filter elements are essential components in various industrial applications, providing critical filtration to ensure the efficiency and longevity of systems. However, to maintain their effectiveness, regular maintenance is paramount. Proper care not only extends the lifespan of these filter elements but also enhances their performance, ensuring that they continue to operate at optimal levels. To achieve this, several maintenance tips should be considered.

First and foremost, it is crucial to establish a routine inspection schedule. Regularly checking the condition of high flow filter elements allows for the early detection of any potential issues, such as clogging or damage. During these inspections, operators should look for signs of wear, such as discoloration or physical deformities, which may indicate that the filter is nearing the end of its service life. Additionally, monitoring pressure differentials across the filter can provide valuable insights into its performance. A significant increase in pressure drop may suggest that the filter is becoming clogged and requires cleaning or replacement.

In conjunction with routine inspections, cleaning high flow filter elements is an essential maintenance practice. Depending on the application and the type of contaminants being filtered, some elements can be cleaned and reused, while others may need to be replaced entirely. For reusable filters, a thorough cleaning process should be employed, which may involve backwashing or using appropriate solvents to remove accumulated debris. It is important to follow the manufacturer’s guidelines during this process to avoid damaging the filter media. Furthermore, ensuring that the cleaning method is compatible with the filter material will help maintain its integrity and performance.

Another critical aspect of maintenance is the proper storage of high flow filter elements when they are not in use. Filters should be stored in a clean, dry environment to prevent contamination from dust, moisture, or other environmental factors. It is advisable to keep them in their original packaging until they are ready to be installed. This practice not only protects the filters from physical damage but also ensures that they remain free from contaminants that could compromise their effectiveness upon installation.

Moreover, it is essential to adhere to the manufacturer’s recommendations regarding replacement intervals. While some filters may appear to be functioning well, they may not be providing adequate filtration if they have exceeded their recommended service life. Regularly replacing filters as per the manufacturer’s guidelines helps maintain system efficiency and prevents costly downtime due to unexpected failures.

In addition to these practices, training personnel on the importance of filter maintenance cannot be overlooked. Ensuring that staff members are knowledgeable about the proper handling, installation, and maintenance of high flow filter elements fosters a culture of care and responsibility. This training should include understanding the specific requirements of the filters used in their systems, as well as the consequences of neglecting maintenance.

In conclusion, maintaining high flow filter elements is vital for ensuring their longevity and efficiency. By implementing routine inspections, proper cleaning techniques, appropriate storage practices, adhering to replacement schedules, and training personnel, organizations can significantly enhance the performance and lifespan of their filtration systems. Ultimately, these maintenance tips not only contribute to the reliability of operations but also promote a more sustainable approach to industrial processes, reducing waste and optimizing resource use.