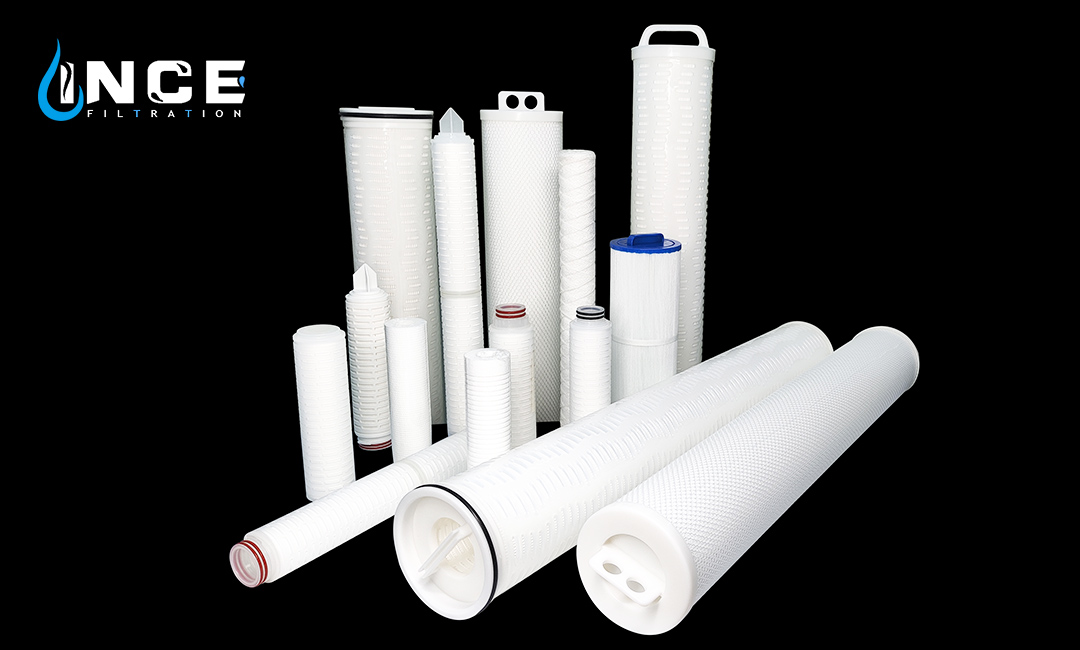

High Flow Pleated Cartridges: An Innovation in Filtration Technology

Advantages of High Flow Pleated Cartridges in Industrial Applications

High flow pleated cartridges represent a significant advancement in filtration technology, particularly within industrial applications. These cartridges are designed to enhance the efficiency and effectiveness of filtration processes, addressing the growing demands for cleaner fluids and improved operational performance. One of the primary advantages of high flow pleated cartridges is their ability to provide a larger surface area compared to traditional filter media. This increased surface area allows for a higher flow rate while maintaining optimal filtration efficiency, which is crucial in industries where large volumes of liquids need to be processed quickly and effectively.

Moreover, the pleated design of these cartridges facilitates a more uniform flow distribution, reducing the risk of channeling and ensuring that the entire filter media is utilized. This characteristic not only enhances the lifespan of the cartridge but also minimizes the frequency of replacements, leading to significant cost savings over time. In addition to their economic benefits, high flow pleated cartridges also contribute to sustainability efforts by reducing waste generated from discarded filters. As industries increasingly prioritize environmental responsibility, the longevity and efficiency of these cartridges align well with green initiatives.

Another notable advantage is their versatility in handling various types of fluids, including water, chemicals, and oils. This adaptability makes high flow pleated cartridges suitable for a wide range of industrial applications, from food and beverage processing to pharmaceuticals and petrochemicals. The ability to filter out particulates, bacteria, and other contaminants effectively ensures that the end products meet stringent quality standards, which is essential in maintaining compliance with regulatory requirements. Furthermore, the materials used in the construction of these cartridges are often resistant to a variety of chemicals, enhancing their durability and performance in challenging environments.

Transitioning to the operational aspects, high flow pleated cartridges are designed for easy installation and maintenance. Their compatibility with existing filtration systems allows for seamless integration, minimizing downtime during upgrades or replacements. This ease of use is particularly beneficial in industries where time is of the essence, as it enables facilities to maintain continuous operations without significant interruptions. Additionally, the reduced maintenance requirements associated with these cartridges free up valuable resources, allowing personnel to focus on other critical tasks within the facility.

In terms of performance, high flow pleated cartridges excel in providing consistent filtration results. Their design minimizes pressure drop, which is a common issue in traditional filtration systems. By maintaining lower pressure differentials, these cartridges not only enhance the overall efficiency of the filtration process but also contribute to energy savings. This aspect is particularly relevant in large-scale industrial operations where energy consumption can significantly impact operational costs.

In conclusion, the advantages of high flow pleated cartridges in industrial applications are manifold. Their ability to provide a larger surface area for filtration, coupled with their versatility and ease of maintenance, positions them as a superior choice for industries seeking to optimize their filtration processes. As the demand for efficient and sustainable filtration solutions continues to grow, high flow pleated cartridges stand out as a pivotal innovation in the realm of filtration technology, promising enhanced performance, cost savings, and environmental benefits. As industries evolve and adapt to new challenges, the adoption of such advanced filtration solutions will undoubtedly play a crucial role in achieving operational excellence and sustainability.

Comparing High Flow Pleated Cartridges to Traditional Filtration Methods

High flow pleated cartridges represent a significant advancement in filtration technology, particularly when compared to traditional filtration methods. As industries increasingly seek efficient and effective solutions for their filtration needs, understanding the distinctions between these modern cartridges and conventional systems becomes essential. Traditional filtration methods, such as bag filters and depth filters, have long been the standard in various applications, but they often come with limitations that high flow pleated cartridges effectively address.

One of the primary advantages of high flow pleated cartridges is their superior surface area, which allows for increased flow rates without compromising filtration efficiency. Traditional filters, particularly bag filters, tend to have a limited surface area, which can lead to rapid clogging and necessitate frequent replacements. In contrast, the pleated design of high flow cartridges maximizes the available surface area, enabling them to handle higher volumes of fluid while maintaining optimal performance over extended periods. This characteristic not only reduces the frequency of filter changes but also minimizes downtime and operational costs, making high flow pleated cartridges a more economical choice in the long run.

Moreover, the materials used in high flow pleated cartridges are often engineered to enhance filtration efficiency and durability. Many traditional filters utilize materials that may not withstand harsh operating conditions, leading to premature failure and contamination of the filtered fluid. High flow pleated cartridges, on the other hand, are typically constructed from advanced synthetic materials that offer greater chemical resistance and mechanical strength. This resilience ensures that they can perform effectively in a wider range of applications, from water treatment to food and beverage processing, without the risk of filter degradation.

In addition to their robust construction, high flow pleated cartridges also provide a more consistent filtration performance. Traditional filtration methods can exhibit variability in their filtration capabilities due to factors such as media loading and flow dynamics. This inconsistency can result in suboptimal filtration and potential product contamination. High flow pleated cartridges, with their uniform pleat design and optimized flow characteristics, deliver a more reliable filtration process. This reliability is particularly crucial in industries where product purity is paramount, such as pharmaceuticals and electronics manufacturing.

Furthermore, the installation and maintenance of high flow pleated cartridges are generally more straightforward than those of traditional filtration systems. Many high flow cartridges are designed for easy integration into existing filtration setups, allowing for quick replacements without the need for extensive modifications. This ease of use not only saves time but also reduces the likelihood of operational disruptions. In contrast, traditional filtration systems often require more complex maintenance procedures, which can lead to increased labor costs and potential errors during filter changes.

As industries continue to evolve and demand more efficient filtration solutions, high flow pleated cartridges stand out as a modern alternative to traditional methods. Their enhanced surface area, durable materials, consistent performance, and ease of maintenance make them an attractive option for a variety of applications. By adopting high flow pleated cartridges, organizations can improve their filtration processes, reduce operational costs, and ensure the integrity of their products. In conclusion, the transition from traditional filtration methods to high flow pleated cartridges not only reflects a technological advancement but also signifies a commitment to efficiency and quality in filtration practices.

The Role of High Flow Pleated Cartridges in Water Treatment Systems

Water treatment systems play a crucial role in ensuring the safety and quality of our drinking water. One key component of these systems is the filtration technology used to remove impurities and contaminants from the water. In recent years, high flow pleated cartridges have emerged as an innovative solution in this field.

High flow pleated cartridges are designed to handle large volumes of water while maintaining high levels of filtration efficiency. Unlike traditional filters, which often have limited flow rates and require frequent replacements, high flow pleated cartridges offer a more efficient and cost-effective solution.

One of the main advantages of high flow pleated cartridges is their ability to handle high flow rates. This makes them ideal for applications where large volumes of water need to be treated, such as industrial processes or municipal water treatment plants. By allowing water to pass through at a faster rate, these cartridges can significantly reduce the time and energy required for filtration.

Another key feature of high flow pleated cartridges is their superior filtration efficiency. The pleated design increases the surface area available for filtration, allowing for more effective removal of particles and contaminants. This means that even small particles, such as sediment or bacteria, can be effectively captured and removed from the water.

Furthermore, high flow pleated cartridges are designed to have a longer lifespan compared to traditional filters. This is due to their larger surface area and the use of durable materials. As a result, these cartridges require less frequent replacements, reducing maintenance costs and downtime.

In addition to their efficiency and durability, high flow pleated cartridges also offer easy installation and maintenance. They are designed to fit into standard filter housings, making it simple to integrate them into existing water treatment systems. Moreover, their larger size means that fewer cartridges are needed, further simplifying the installation process.

Maintenance is also made easier by the design of high flow pleated cartridges. They can be easily cleaned and reused, reducing the need for frequent replacements. This not only saves time and money but also reduces waste and environmental impact.

High flow pleated cartridges are also compatible with a wide range of filtration media, allowing for customization based on specific water treatment needs. Whether it is removing chlorine, heavy metals, or organic compounds, these cartridges can be tailored to meet the requirements of different applications.

In conclusion, high flow pleated cartridges have revolutionized the field of water treatment systems. Their ability to handle high flow rates, superior filtration efficiency, and longer lifespan make them an ideal choice for various applications. With easy installation and maintenance, as well as compatibility with different filtration media, these cartridges offer a cost-effective and sustainable solution for ensuring the safety and quality of our drinking water. As technology continues to advance, high flow pleated cartridges are likely to play an even more significant role in the future of water treatment.

Future Trends in High Flow Pleated Cartridge Technology

High flow pleated cartridges are a revolutionary innovation in filtration technology that is changing the way industries approach liquid filtration. These cartridges are designed to handle high flow rates while maintaining efficiency and effectiveness in removing contaminants from liquids. As industries continue to evolve and demand higher flow rates for their filtration systems, high flow pleated cartridges are becoming increasingly popular due to their superior performance and cost-effectiveness.

One of the key advantages of high flow pleated cartridges is their ability to handle significantly higher flow rates compared to traditional filter cartridges. This is achieved through the unique design of the pleated cartridges, which allows for a larger surface area for filtration. The pleated design increases the filtration area without increasing the overall size of the cartridge, making it a compact and efficient solution for high flow applications.

In addition to their high flow capabilities, pleated cartridges are also known for their exceptional dirt-holding capacity. The pleated design creates more space for contaminants to be captured, resulting in longer service life and fewer cartridge changeouts. This not only reduces maintenance costs but also minimizes downtime, making high flow pleated cartridges a reliable and cost-effective filtration solution for industries with high flow rate requirements.

Furthermore, high flow pleated cartridges are designed to provide consistent and reliable filtration performance over time. The pleated design ensures uniform flow distribution across the entire filtration surface, preventing channeling and ensuring that all contaminants are captured effectively. This results in a more efficient filtration process and cleaner liquids, which is crucial for industries that require high-quality filtered liquids for their operations.

Another key benefit of high flow pleated cartridges is their compatibility with a wide range of liquids and applications. These cartridges are available in various materials and micron ratings to suit different filtration needs, making them versatile and adaptable to different industries and processes. Whether filtering water, chemicals, oils, or other liquids, high flow pleated cartridges can provide the necessary filtration performance to meet the specific requirements of each application.

As industries continue to advance and demand higher flow rates for their filtration systems, the need for innovative filtration solutions like high flow pleated cartridges will only continue to grow. These cartridges offer a combination of high flow capabilities, exceptional dirt-holding capacity, consistent performance, and versatility that make them an ideal choice for a wide range of applications. With their superior performance and cost-effectiveness, high flow pleated cartridges are poised to become the future trend in filtration technology.

In conclusion, high flow pleated cartridges represent a significant advancement in filtration technology that is revolutionizing the way industries approach liquid filtration. With their high flow capabilities, exceptional dirt-holding capacity, consistent performance, and versatility, these cartridges offer a superior filtration solution for industries with high flow rate requirements. As industries continue to evolve and demand more efficient and cost-effective filtration solutions, high flow pleated cartridges are set to become the future trend in filtration technology.