High Flow Pleated Filter Cartridges Explained: A Comprehensive Guide

Benefits of Using High Flow Pleated Filter Cartridges

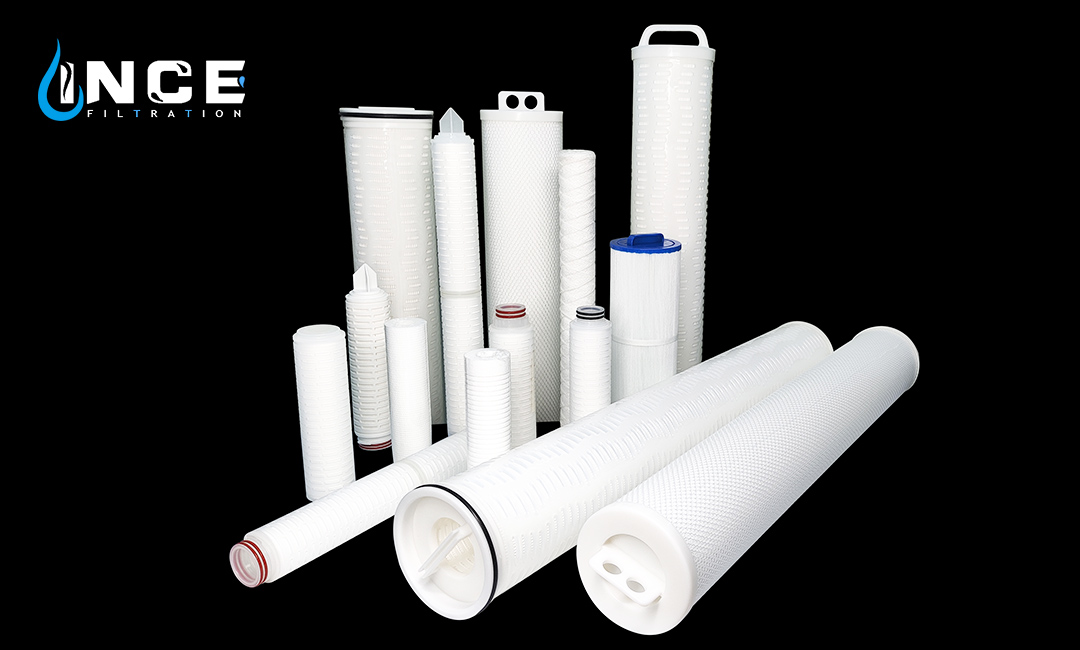

High flow pleated filter cartridges are an essential component in many industrial and commercial filtration systems. These cartridges offer a number of benefits that make them a popular choice for a wide range of applications. In this comprehensive guide, we will explore the benefits of using high flow pleated filter cartridges and why they are a superior choice for many filtration needs.

One of the primary benefits of high flow pleated filter cartridges is their increased filtration efficiency. These cartridges are designed with a larger surface area than traditional filter cartridges, allowing them to capture more contaminants and particles from the fluid being filtered. This increased efficiency results in cleaner, purer fluid and improved overall system performance.

In addition to their enhanced filtration efficiency, high flow pleated filter cartridges also offer a longer service life than traditional filter cartridges. The pleated design of these cartridges allows for a greater amount of particulate matter to be captured before the cartridge needs to be replaced. This extended service life not only reduces maintenance costs but also minimizes system downtime, making high flow pleated filter cartridges a cost-effective choice for many applications.

Another key benefit of using high flow pleated filter cartridges is their high flow rates. These cartridges are specifically designed to handle high flow rates, making them ideal for applications where a large volume of fluid needs to be filtered quickly and efficiently. Whether you are filtering water, chemicals, or other fluids, high flow pleated filter cartridges can help you achieve the flow rates you need without sacrificing filtration quality.

Furthermore, high flow pleated filter cartridges are easy to install and replace, making them a convenient choice for many filtration systems. These cartridges are typically designed to fit standard filter housings, allowing for easy integration into existing systems. Additionally, their pleated design makes them easy to remove and replace when necessary, minimizing downtime and ensuring that your filtration system remains operational.

In addition to their practical benefits, high flow pleated filter cartridges are also environmentally friendly. By capturing more contaminants and particles from the fluid being filtered, these cartridges help to reduce waste and minimize environmental impact. This can be especially important in applications where the filtered fluid is discharged back into the environment, such as in wastewater treatment systems.

Overall, high flow pleated filter cartridges offer a number of benefits that make them a superior choice for many filtration applications. From their increased filtration efficiency and longer service life to their high flow rates and ease of installation, these cartridges provide a cost-effective and environmentally friendly solution for a wide range of filtration needs. Whether you are filtering water, chemicals, or other fluids, high flow pleated filter cartridges can help you achieve cleaner, purer fluid and improved system performance.

How High Flow Pleated Filter Cartridges Work

High flow pleated filter cartridges are an essential component in many industrial and commercial filtration systems. These cartridges are designed to handle high flow rates while effectively removing contaminants from liquids. Understanding how high flow pleated filter cartridges work is crucial for ensuring optimal performance and efficiency in filtration systems.

At the core of a high flow pleated filter cartridge is a pleated filter media. This media is made up of a series of pleats or folds that increase the surface area available for filtration. The pleats create a larger filtration area within a compact cartridge, allowing for higher flow rates without sacrificing filtration efficiency.

The pleated filter media is typically made from materials such as polypropylene, polyester, or cellulose. These materials are chosen for their ability to effectively capture contaminants while maintaining high flow rates. The pleats in the filter media create a tortuous path for the liquid to flow through, trapping particles and impurities along the way.

One of the key advantages of high flow pleated filter cartridges is their ability to handle a large volume of liquid flow. Traditional filter cartridges may struggle to keep up with high flow rates, leading to reduced filtration efficiency and increased maintenance requirements. High flow pleated filter cartridges are specifically designed to handle these high flow rates, making them ideal for applications where large volumes of liquid need to be filtered quickly and efficiently.

In addition to their high flow capabilities, pleated filter cartridges are also known for their long service life. The pleated design of the filter media helps to prevent premature clogging and extends the time between filter replacements. This not only reduces maintenance costs but also ensures consistent filtration performance over time.

The pleated filter media in high flow filter cartridges is supported by a rigid core that helps maintain the shape and integrity of the cartridge. This core also provides structural support, preventing the pleats from collapsing under high flow rates. The combination of pleated filter media and a sturdy core ensures that the cartridge can withstand the rigors of industrial filtration applications.

High flow pleated filter cartridges are available in a variety of sizes and micron ratings to suit different filtration needs. The micron rating refers to the size of particles that the filter can effectively capture. Lower micron ratings indicate finer filtration, while higher micron ratings are suitable for larger particles.

In conclusion, high flow pleated filter cartridges are a versatile and efficient filtration solution for industrial and commercial applications. Their unique design allows for high flow rates without compromising filtration efficiency, making them ideal for applications where large volumes of liquid need to be filtered quickly and effectively. By understanding how high flow pleated filter cartridges work, users can ensure that their filtration systems operate at peak performance and deliver clean, contaminant-free liquids.

Factors to Consider When Choosing High Flow Pleated Filter Cartridges

High flow pleated filter cartridges are an essential component in many industrial processes, providing efficient filtration of liquids and gases. When choosing the right high flow pleated filter cartridge for your application, there are several factors to consider to ensure optimal performance and longevity.

One of the most important factors to consider when selecting a high flow pleated filter cartridge is the filtration efficiency. The filtration efficiency of a filter cartridge is determined by its ability to remove contaminants from the fluid or gas being filtered. High flow pleated filter cartridges are available in a range of filtration efficiencies, typically measured in microns. The lower the micron rating, the finer the particles that can be captured by the filter cartridge. It is important to select a filter cartridge with the appropriate filtration efficiency for your specific application to ensure effective filtration.

Another important factor to consider when choosing a high flow pleated filter cartridge is the flow rate. The flow rate of a filter cartridge is the rate at which fluid or gas can pass through the filter media. High flow pleated filter cartridges are designed to handle high flow rates, making them ideal for applications that require fast filtration. It is important to select a filter cartridge with a flow rate that matches the requirements of your application to prevent clogging and ensure efficient filtration.

In addition to filtration efficiency and flow rate, it is important to consider the material construction of the high flow pleated filter cartridge. Filter cartridges are typically made from a variety of materials, including polypropylene, polyester, and fiberglass. The material construction of the filter cartridge will impact its compatibility with different fluids and gases, as well as its resistance to chemicals and high temperatures. It is important to select a filter cartridge made from a material that is compatible with the fluid or gas being filtered and can withstand the operating conditions of your application.

The size and dimensions of the high flow pleated filter cartridge are also important factors to consider when choosing a filter cartridge. Filter cartridges are available in a range of sizes and configurations to accommodate different flow rates and installation requirements. It is important to select a filter cartridge that fits the dimensions of your filtration system and can handle the flow rate of your application. Additionally, the design of the filter cartridge, including the number of pleats and the spacing between pleats, can impact its filtration efficiency and dirt-holding capacity.

When selecting a high flow pleated filter cartridge, it is important to consider the overall cost of the filter cartridge, including the initial purchase price and ongoing maintenance costs. While high flow pleated filter cartridges may have a higher upfront cost compared to standard filter cartridges, they offer longer service life and higher dirt-holding capacity, resulting in lower overall operating costs. It is important to consider the total cost of ownership when selecting a filter cartridge to ensure cost-effective filtration.

In conclusion, there are several factors to consider when choosing a high flow pleated filter cartridge for your application, including filtration efficiency, flow rate, material construction, size and dimensions, and overall cost. By carefully evaluating these factors and selecting a filter cartridge that meets the requirements of your application, you can ensure efficient filtration and optimal performance.

Maintenance and Cleaning Tips for High Flow Pleated Filter Cartridges

High flow pleated filter cartridges are an essential component in many industrial and commercial filtration systems. These cartridges are designed to handle high flow rates while effectively removing contaminants from liquids. To ensure the optimal performance of high flow pleated filter cartridges, proper maintenance and cleaning are crucial. In this comprehensive guide, we will discuss some important tips for maintaining and cleaning high flow pleated filter cartridges.

Regular maintenance is key to ensuring the longevity and efficiency of high flow pleated filter cartridges. One of the most important maintenance tasks is to regularly inspect the cartridges for any signs of damage or clogging. Inspecting the cartridges can help identify any issues early on and prevent them from causing more serious problems down the line.

In addition to regular inspections, it is also important to replace the cartridges on a regular basis. Over time, the pleats in the cartridges can become clogged with contaminants, reducing their effectiveness. By replacing the cartridges according to the manufacturer’s recommendations, you can ensure that your filtration system continues to operate at peak performance.

Cleaning high flow pleated filter cartridges is another important maintenance task. While some cartridges are designed to be disposable and replaced when they become clogged, others can be cleaned and reused multiple times. To clean pleated filter cartridges, you will need to follow a few simple steps.

First, remove the cartridges from the filtration system and rinse them with clean water to remove any surface contaminants. Next, soak the cartridges in a cleaning solution that is specifically designed for pleated filter cartridges. Be sure to follow the manufacturer’s instructions for the cleaning solution and the recommended soaking time.

After soaking, rinse the cartridges again with clean water to remove any remaining cleaning solution. Finally, allow the cartridges to dry completely before reinstalling them in the filtration system. It is important to ensure that the cartridges are completely dry before reusing them to prevent the growth of mold or bacteria.

In addition to regular maintenance and cleaning, there are a few other tips that can help prolong the life of high flow pleated filter cartridges. One important tip is to avoid exposing the cartridges to extreme temperatures or harsh chemicals, as this can damage the pleats and reduce their effectiveness.

Another tip is to handle the cartridges with care to avoid damaging the pleats. When installing or removing the cartridges, be sure to follow the manufacturer’s instructions and avoid bending or twisting the cartridges. Proper handling can help prevent damage and ensure that the cartridges continue to perform effectively.

In conclusion, proper maintenance and cleaning are essential for ensuring the optimal performance of high flow pleated filter cartridges. By following the tips outlined in this guide, you can help prolong the life of your cartridges and keep your filtration system operating at peak efficiency. Remember to regularly inspect, replace, and clean the cartridges to ensure that your filtration system continues to provide clean, contaminant-free liquids.