High Flow Pleated Filters: Revolutionizing Industrial Water Treatment

Benefits of High Flow Pleated Filters in Industrial Water Treatment

High flow pleated filters have revolutionized the way industrial water treatment is conducted. These filters offer numerous benefits that make them a popular choice for companies looking to improve their water treatment processes. In this article, we will explore the advantages of high flow pleated filters in industrial water treatment.

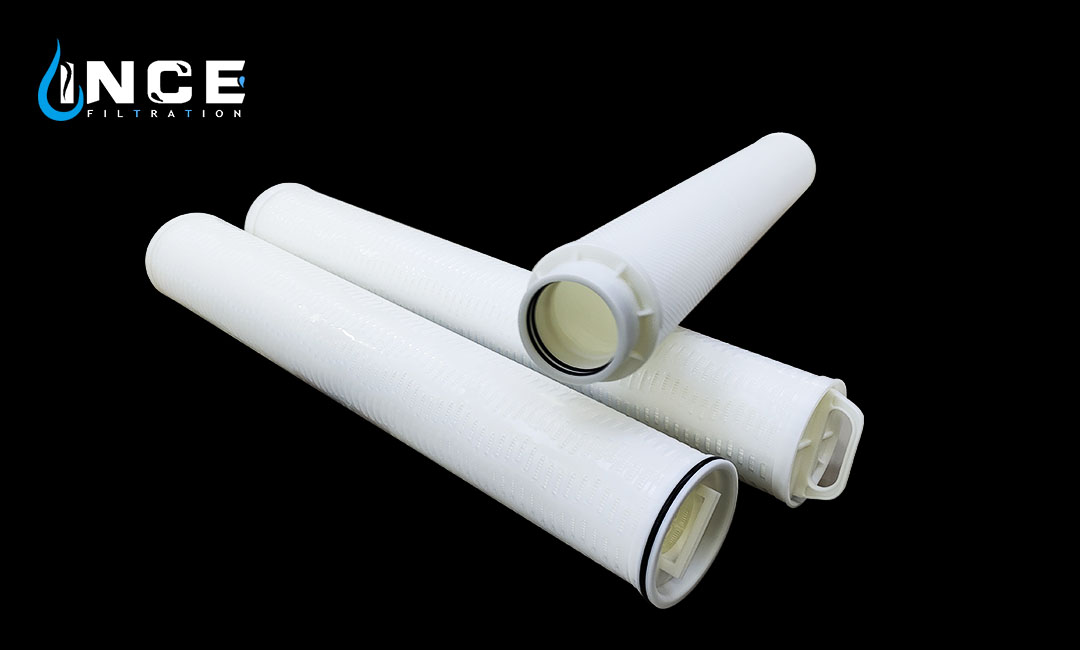

One of the key benefits of high flow pleated filters is their efficiency. These filters are designed to handle high flow rates, allowing for faster water treatment processes. This can help companies save time and money by reducing the amount of time it takes to treat water. Additionally, high flow pleated filters are capable of removing a wide range of contaminants from water, making them a versatile option for industrial water treatment.

Another advantage of high flow pleated filters is their durability. These filters are constructed from high-quality materials that are designed to withstand the harsh conditions often found in industrial settings. This means that high flow pleated filters are less likely to break or become damaged during the water treatment process, reducing the need for frequent replacements and maintenance.

In addition to their efficiency and durability, high flow pleated filters are also easy to install and maintain. These filters can be quickly and easily installed in existing water treatment systems, allowing companies to upgrade their processes without significant downtime. Additionally, high flow pleated filters are designed to be easy to clean and maintain, further reducing the time and effort required to keep them in optimal working condition.

High flow pleated filters are also cost-effective. These filters are designed to be long-lasting, reducing the need for frequent replacements. Additionally, the efficiency of high flow pleated filters means that companies can treat water more quickly and with less energy, saving money on utility costs. Overall, high flow pleated filters offer a cost-effective solution for industrial water treatment.

Furthermore, high flow pleated filters are environmentally friendly. These filters are designed to remove contaminants from water without the need for harsh chemicals, making them a more sustainable option for water treatment. By using high flow pleated filters, companies can reduce their environmental impact and contribute to a cleaner, healthier planet.

In conclusion, high flow pleated filters offer numerous benefits for industrial water treatment. From their efficiency and durability to their cost-effectiveness and environmental friendliness, these filters are a versatile and effective option for companies looking to improve their water treatment processes. By investing in high flow pleated filters, companies can save time and money, while also reducing their environmental impact. Overall, high flow pleated filters are a valuable tool for companies looking to enhance their industrial water treatment processes.

How High Flow Pleated Filters Improve Efficiency in Water Treatment Processes

High flow pleated filters have become a game-changer in the field of industrial water treatment. These filters are designed to handle high flow rates while maintaining efficiency and effectiveness in removing contaminants from water. In this article, we will explore how high flow pleated filters are revolutionizing industrial water treatment processes by improving efficiency and performance.

One of the key advantages of high flow pleated filters is their ability to handle a large volume of water flow without sacrificing filtration quality. Traditional filters may struggle to keep up with high flow rates, leading to decreased efficiency and potential contamination of the water supply. High flow pleated filters, on the other hand, are specifically designed to handle high flow rates, making them ideal for industrial applications where large volumes of water need to be treated quickly and effectively.

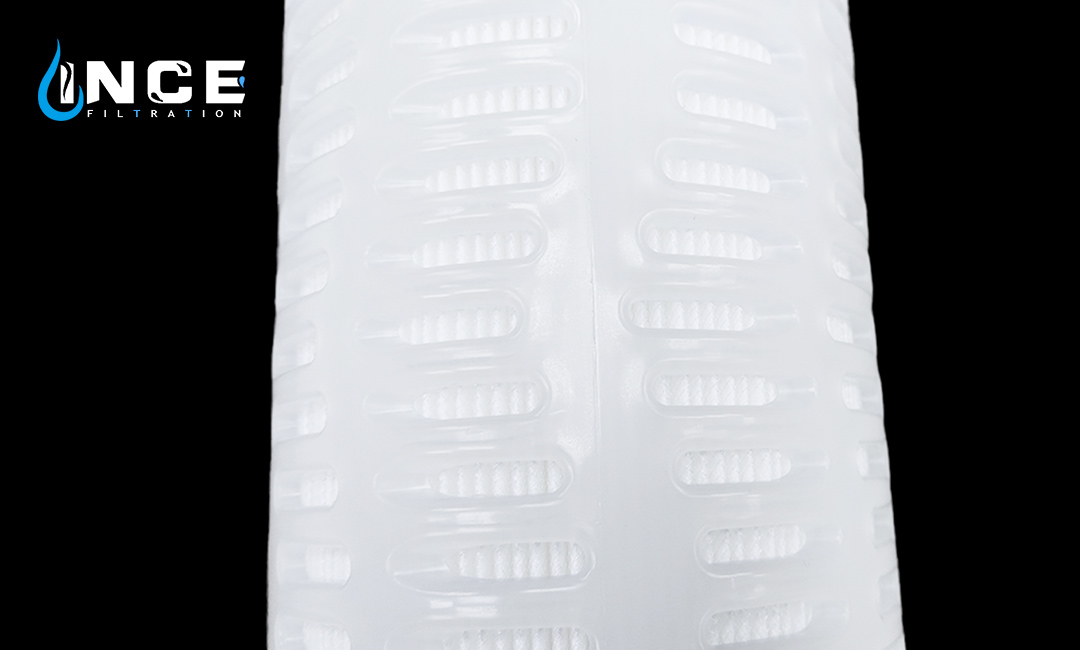

In addition to their high flow capacity, pleated filters also offer superior filtration performance. The pleated design of these filters provides a larger surface area for filtration, allowing them to capture more contaminants and particles from the water. This results in cleaner, safer water that meets industry standards for quality and purity. By using high flow pleated filters, industrial facilities can ensure that their water treatment processes are efficient and effective in removing harmful substances from the water supply.

Another benefit of high flow pleated filters is their long lifespan and durability. These filters are made from high-quality materials that are designed to withstand the rigors of industrial use. Unlike traditional filters that may need to be replaced frequently, high flow pleated filters can last for an extended period of time without losing their effectiveness. This not only reduces maintenance costs for industrial facilities but also ensures that water treatment processes can continue uninterrupted without the need for frequent filter changes.

Furthermore, high flow pleated filters are easy to install and maintain, making them a convenient option for industrial water treatment systems. These filters can be quickly and easily replaced when needed, minimizing downtime and ensuring that water treatment processes can continue without interruption. Additionally, the pleated design of these filters allows for easy cleaning and maintenance, further extending their lifespan and ensuring optimal performance over time.

Overall, high flow pleated filters are revolutionizing industrial water treatment processes by improving efficiency, performance, and reliability. These filters are specifically designed to handle high flow rates while providing superior filtration performance, making them an ideal choice for industrial facilities that require clean, safe water for their operations. With their long lifespan, durability, and ease of maintenance, high flow pleated filters offer a cost-effective and efficient solution for industrial water treatment needs.

In conclusion, high flow pleated filters are a valuable asset for industrial facilities looking to improve their water treatment processes. By utilizing these filters, industrial facilities can ensure that their water supply is clean, safe, and free from contaminants. With their high flow capacity, superior filtration performance, and long lifespan, high flow pleated filters are revolutionizing the way industrial facilities approach water treatment.

The Role of High Flow Pleated Filters in Enhancing Water Quality

High flow pleated filters have become a game-changer in the realm of industrial water treatment. These innovative filters are designed to handle high flow rates while effectively removing contaminants from water, making them an essential component in ensuring water quality in various industrial applications.

One of the key advantages of high flow pleated filters is their ability to handle a large volume of water without compromising filtration efficiency. Traditional filters may struggle to keep up with high flow rates, leading to decreased filtration performance and potential system failures. High flow pleated filters, on the other hand, are specifically engineered to handle high flow rates, making them ideal for industrial settings where large volumes of water need to be treated quickly and efficiently.

In addition to their high flow capacity, high flow pleated filters are also known for their superior filtration efficiency. These filters are designed with a large surface area and a pleated design, allowing them to capture a wide range of contaminants, including sediment, dirt, rust, and other particles that can compromise water quality. By effectively removing these contaminants, high flow pleated filters help to ensure that the water used in industrial processes meets the required quality standards.

Furthermore, high flow pleated filters are easy to install and maintain, making them a cost-effective solution for industrial water treatment. These filters can be quickly and easily replaced when needed, minimizing downtime and ensuring that water treatment systems remain operational. Additionally, the durable construction of high flow pleated filters means that they can withstand harsh operating conditions, making them a reliable and long-lasting solution for industrial water treatment.

The use of high flow pleated filters in industrial water treatment has numerous benefits, including improved water quality, increased system efficiency, and reduced maintenance costs. By effectively removing contaminants from water, these filters help to protect equipment and processes from damage, ensuring that industrial operations run smoothly and efficiently.

In conclusion, high flow pleated filters are revolutionizing industrial water treatment by providing a reliable and efficient solution for handling high flow rates and removing contaminants from water. With their superior filtration efficiency, ease of installation and maintenance, and durability, these filters are an essential component in ensuring water quality in various industrial applications. As industries continue to prioritize water quality and sustainability, high flow pleated filters will play an increasingly important role in meeting these goals and ensuring the long-term success of industrial operations.

High Flow Pleated Filters: A Sustainable Solution for Industrial Water Treatment

High flow pleated filters have emerged as a revolutionary solution for industrial water treatment, offering a sustainable and efficient way to remove contaminants from water. These filters are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for a wide range of industrial applications.

One of the key advantages of high flow pleated filters is their ability to handle large volumes of water without sacrificing filtration performance. Traditional filters often struggle to maintain their efficiency at high flow rates, leading to increased maintenance costs and decreased overall effectiveness. High flow pleated filters, on the other hand, are specifically engineered to handle high flow rates while still providing excellent filtration results.

In addition to their high flow capabilities, pleated filters are also known for their durability and longevity. These filters are constructed from high-quality materials that are designed to withstand the rigors of industrial use, ensuring that they will continue to perform effectively over an extended period of time. This durability not only reduces maintenance costs but also helps to minimize downtime and ensure that water treatment processes can continue uninterrupted.

Another key benefit of high flow pleated filters is their sustainability. These filters are designed to be reusable, allowing them to be cleaned and reused multiple times before needing to be replaced. This not only reduces waste but also helps to lower overall operating costs, making high flow pleated filters a cost-effective and environmentally friendly option for industrial water treatment.

Furthermore, high flow pleated filters are highly versatile and can be customized to meet the specific needs of different industrial applications. Whether filtering out sediment, contaminants, or other impurities, these filters can be tailored to provide the level of filtration required for each unique situation. This flexibility makes high flow pleated filters a valuable tool for a wide range of industries, from manufacturing and food processing to pharmaceuticals and wastewater treatment.

In conclusion, high flow pleated filters are revolutionizing industrial water treatment by offering a sustainable, efficient, and cost-effective solution for removing contaminants from water. With their high flow capabilities, durability, and versatility, these filters are quickly becoming the go-to choice for industries looking to improve their water treatment processes. By investing in high flow pleated filters, companies can not only improve the quality of their water but also reduce costs, minimize downtime, and contribute to a more sustainable future.