High Flow Pleated Filters vs. Traditional Filters: A Performance Comparison

Benefits of High Flow Pleated Filters

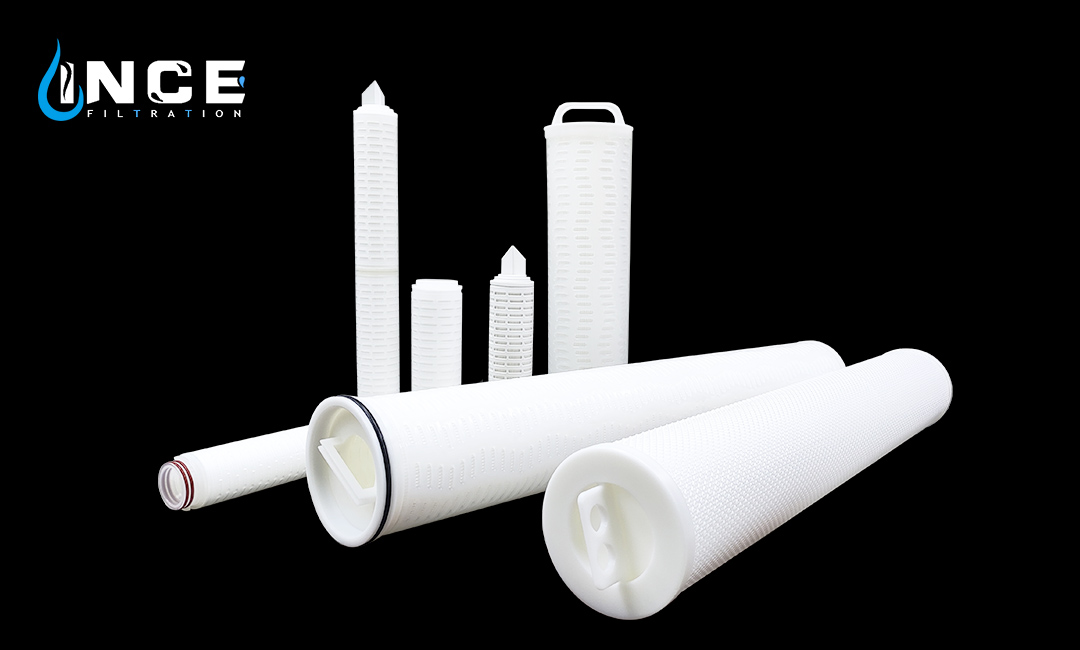

High flow pleated filters have become increasingly popular in recent years due to their superior performance compared to traditional filters. These filters are designed to handle higher flow rates while maintaining efficiency and durability. In this article, we will explore the benefits of high flow pleated filters and compare them to traditional filters to highlight their advantages.

One of the key benefits of high flow pleated filters is their increased surface area. Traditional filters have a limited surface area, which can lead to clogging and reduced efficiency over time. High flow pleated filters, on the other hand, have a larger surface area due to their pleated design. This allows them to capture more contaminants and particles without clogging, resulting in improved performance and longer filter life.

Another advantage of high flow pleated filters is their higher dirt-holding capacity. Traditional filters can quickly become saturated with contaminants, leading to reduced flow rates and increased pressure drop. High flow pleated filters are designed to hold more dirt and debris, allowing them to maintain optimal flow rates for longer periods. This not only improves the efficiency of the filtration system but also reduces maintenance costs and downtime.

In addition to their increased surface area and dirt-holding capacity, high flow pleated filters also offer better filtration efficiency. Traditional filters may allow some particles to pass through, compromising the quality of the filtrate. High flow pleated filters are designed to capture even the smallest particles, ensuring that the filtrate is clean and free of contaminants. This is especially important in applications where the quality of the filtrate is critical, such as in the pharmaceutical or food and beverage industries.

Furthermore, high flow pleated filters are more durable and resistant to damage compared to traditional filters. The pleated design provides structural support and prevents the filter media from collapsing under high flow rates or pressure. This makes high flow pleated filters ideal for demanding applications where reliability and longevity are essential. Additionally, the robust construction of these filters allows them to withstand harsh operating conditions, such as high temperatures or corrosive environments.

Overall, high flow pleated filters offer several advantages over traditional filters, including increased surface area, higher dirt-holding capacity, better filtration efficiency, and improved durability. These benefits make high flow pleated filters a superior choice for applications that require high flow rates, efficient filtration, and long-lasting performance.

In conclusion, high flow pleated filters outperform traditional filters in terms of performance, efficiency, and durability. Their innovative design and superior capabilities make them the ideal choice for a wide range of applications, from industrial processes to water treatment systems. By investing in high flow pleated filters, businesses can improve the quality of their products, reduce maintenance costs, and enhance overall operational efficiency.

Drawbacks of Traditional Filters

Traditional filters have long been a staple in the filtration industry, providing a cost-effective solution for removing contaminants from various fluids. However, as technology advances and demands for higher filtration efficiency increase, traditional filters are starting to show their limitations. In this article, we will explore the drawbacks of traditional filters and compare them to high flow pleated filters to highlight the performance differences between the two.

One of the main drawbacks of traditional filters is their limited surface area. Traditional filters typically have a flat design, which restricts the amount of filter media available for capturing contaminants. This limited surface area can result in a shorter filter life and reduced filtration efficiency, especially when dealing with high flow rates or heavily contaminated fluids.

Additionally, traditional filters are prone to clogging. As contaminants accumulate on the filter media, the flow rate through the filter decreases, leading to pressure drops and reduced system performance. This clogging effect can result in frequent filter replacements and increased maintenance costs, making traditional filters less cost-effective in the long run.

Another drawback of traditional filters is their lower dirt-holding capacity. Traditional filters are often made of paper or cellulose materials, which have limited capacity to hold onto contaminants. This can lead to premature filter failure and decreased filtration efficiency, especially in applications where high levels of contaminants are present.

Furthermore, traditional filters are not as versatile as high flow pleated filters. Traditional filters are typically designed for specific applications and flow rates, limiting their flexibility in different operating conditions. High flow pleated filters, on the other hand, are available in a wide range of sizes and configurations, making them suitable for a variety of applications and flow rates.

In conclusion, traditional filters have several drawbacks that can impact their performance and cost-effectiveness in filtration applications. From limited surface area and clogging issues to lower dirt-holding capacity and lack of versatility, traditional filters are starting to fall behind in meeting the demands of modern filtration requirements.

Transitioning to high flow pleated filters can offer significant advantages in terms of filtration efficiency, filter life, and system performance. High flow pleated filters have a larger surface area, higher dirt-holding capacity, and better flow rates compared to traditional filters, making them a superior choice for applications that require high filtration efficiency and long filter life.

By understanding the drawbacks of traditional filters and comparing them to the performance benefits of high flow pleated filters, filtration system designers and operators can make informed decisions on selecting the most suitable filter technology for their specific needs. High flow pleated filters offer a cost-effective solution for achieving higher filtration efficiency and system performance, making them a valuable asset in the filtration industry.

Efficiency Comparison between High Flow Pleated Filters and Traditional Filters

High flow pleated filters and traditional filters are both commonly used in various industries to remove contaminants from liquids and gases. However, there are significant differences in their performance and efficiency. In this article, we will compare the efficiency of high flow pleated filters and traditional filters to help you make an informed decision on which type of filter is best suited for your specific needs.

High flow pleated filters are designed to handle a higher flow rate compared to traditional filters. This means that they can process a larger volume of liquid or gas in a shorter amount of time, making them ideal for applications where high flow rates are required. Traditional filters, on the other hand, have a lower flow rate capacity and may not be able to keep up with the demands of high-flow applications.

In terms of filtration efficiency, high flow pleated filters are known to provide superior performance compared to traditional filters. The pleated design of high flow filters increases the surface area available for filtration, allowing them to capture more contaminants and particles from the liquid or gas passing through. This results in cleaner and purer output, making high flow pleated filters a preferred choice for critical applications where the purity of the filtered product is essential.

Traditional filters, while effective in removing contaminants, may not be as efficient as high flow pleated filters due to their limited surface area for filtration. This can result in a higher pressure drop across the filter, reducing the flow rate and overall efficiency of the filtration process. In contrast, high flow pleated filters offer lower pressure drop and higher flow rates, ensuring optimal performance and efficiency in filtration applications.

Another key difference between high flow pleated filters and traditional filters is their lifespan and maintenance requirements. High flow pleated filters are designed to have a longer service life compared to traditional filters, thanks to their durable construction and efficient filtration capabilities. This means that high flow pleated filters can operate for extended periods without the need for frequent replacements, reducing downtime and maintenance costs.

Traditional filters, on the other hand, may require more frequent replacements due to their lower efficiency and capacity. This can result in increased maintenance costs and downtime, making them less cost-effective in the long run compared to high flow pleated filters. Additionally, the higher flow rates and superior filtration efficiency of high flow pleated filters can help improve overall system performance and reduce energy consumption, further enhancing their cost-effectiveness.

In conclusion, high flow pleated filters outperform traditional filters in terms of efficiency, flow rate capacity, filtration performance, and cost-effectiveness. Their superior design and construction make them an ideal choice for applications where high purity and efficiency are essential. By choosing high flow pleated filters over traditional filters, you can ensure optimal performance and reliability in your filtration system.

Cost Analysis of High Flow Pleated Filters vs. Traditional Filters

When it comes to choosing the right filter for your industrial or commercial application, there are many factors to consider. One of the most important considerations is the cost of the filter and its overall performance. In this article, we will compare the cost analysis of high flow pleated filters versus traditional filters to help you make an informed decision.

High flow pleated filters are designed to handle a higher flow rate than traditional filters, making them ideal for applications where a large volume of fluid needs to be filtered quickly. These filters are typically made from a pleated material that provides a larger surface area for filtration, allowing for more efficient removal of contaminants from the fluid. Traditional filters, on the other hand, are usually made from a single layer of material and may not be able to handle as high of a flow rate as high flow pleated filters.

In terms of cost, high flow pleated filters are generally more expensive upfront than traditional filters. However, when you consider the performance benefits of high flow pleated filters, the cost may be justified. High flow pleated filters can last longer and require less frequent replacement than traditional filters, which can help offset the initial higher cost.

Additionally, high flow pleated filters are more efficient at removing contaminants from the fluid, which can lead to cost savings in the long run. By using a high flow pleated filter, you may be able to reduce the amount of maintenance and downtime required for your equipment, ultimately saving you money in the long term.

Another factor to consider when comparing the cost of high flow pleated filters versus traditional filters is the energy efficiency of the filters. High flow pleated filters are designed to minimize pressure drop across the filter, which can help reduce energy consumption and lower operating costs. Traditional filters may have a higher pressure drop, which can result in increased energy usage and higher operating costs over time.

Overall, when considering the cost analysis of high flow pleated filters versus traditional filters, it is important to weigh the upfront cost of the filter against its long-term performance and efficiency benefits. While high flow pleated filters may be more expensive initially, their superior performance and efficiency can lead to cost savings over time.

In conclusion, high flow pleated filters offer a number of performance benefits over traditional filters, including higher flow rates, more efficient contaminant removal, and lower energy consumption. While high flow pleated filters may be more expensive upfront, their long-term cost savings and performance advantages make them a worthwhile investment for many industrial and commercial applications. By carefully considering the cost analysis of high flow pleated filters versus traditional filters, you can make an informed decision that will benefit your operation in the long run.