How High Flow Filter Cartridges Optimize Industrial Filtration Systems

Benefits of Using High Flow Filter Cartridges in Industrial Filtration Systems

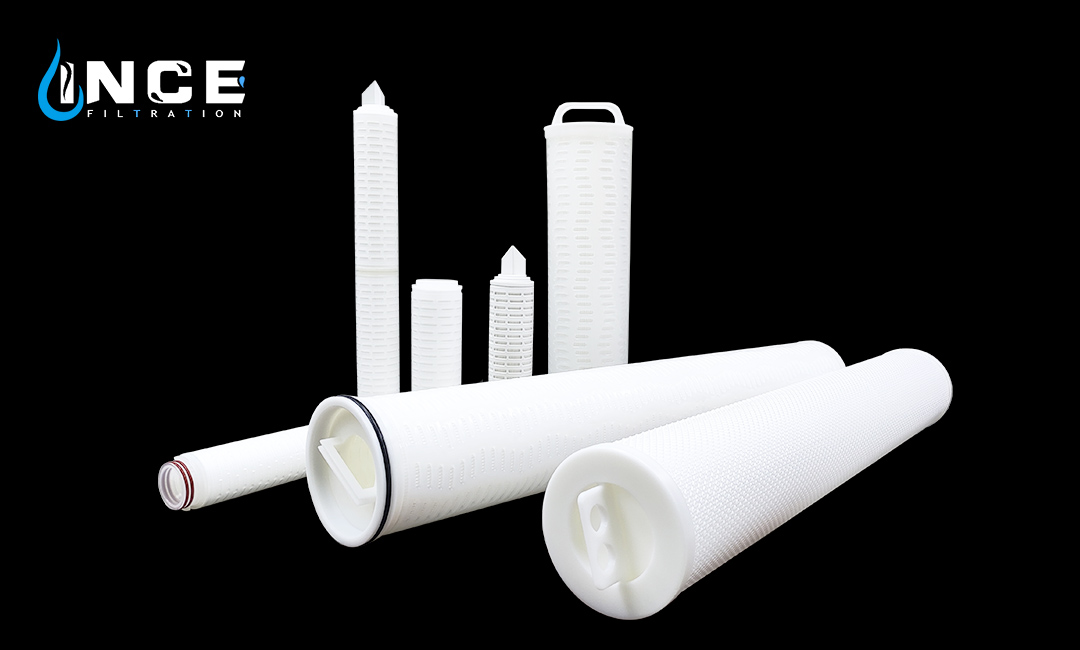

High flow filter cartridges are an essential component of industrial filtration systems, playing a crucial role in ensuring the efficiency and effectiveness of the filtration process. These filter cartridges are designed to handle high flow rates while maintaining optimal filtration performance, making them ideal for industrial applications where large volumes of liquid need to be filtered.

One of the key benefits of using high flow filter cartridges in industrial filtration systems is their ability to handle high flow rates without compromising on filtration efficiency. Traditional filter cartridges may struggle to keep up with the demands of high flow applications, leading to decreased filtration performance and potential system failures. High flow filter cartridges, on the other hand, are specifically designed to handle high flow rates, ensuring that the filtration system operates at peak efficiency even under high flow conditions.

In addition to their high flow capabilities, high flow filter cartridges also offer superior dirt-holding capacity compared to traditional filter cartridges. This means that they can capture and retain a larger volume of contaminants before needing to be replaced, reducing downtime and maintenance costs associated with frequent filter changes. The increased dirt-holding capacity of high flow filter cartridges also helps to prolong the life of the filtration system, ensuring consistent performance over an extended period of time.

Another advantage of using high flow filter cartridges in industrial filtration systems is their compact size and space-saving design. High flow filter cartridges are typically smaller and more lightweight than traditional filter cartridges, making them easier to install and replace in tight spaces. Their compact design also allows for more efficient use of space within the filtration system, maximizing the available filtration area and improving overall system performance.

Furthermore, high flow filter cartridges are available in a variety of materials and configurations to suit different industrial applications. Whether filtering water, chemicals, or other liquids, there is a high flow filter cartridge option that can meet the specific requirements of the application. From pleated to depth filter cartridges, manufacturers offer a wide range of options to ensure that industrial filtration systems are optimized for maximum performance and efficiency.

In conclusion, high flow filter cartridges offer a range of benefits that can help optimize industrial filtration systems. From their ability to handle high flow rates and superior dirt-holding capacity to their compact size and customizable configurations, high flow filter cartridges are a versatile and efficient solution for industrial filtration applications. By incorporating high flow filter cartridges into their filtration systems, industrial operators can ensure that their systems operate at peak performance, with minimal downtime and maintenance costs.

Types of Contaminants High Flow Filter Cartridges Can Remove

High flow filter cartridges are an essential component of industrial filtration systems, designed to remove various types of contaminants from liquids and gases. These filter cartridges are specifically engineered to handle high flow rates, making them ideal for applications where large volumes of fluid need to be filtered quickly and efficiently. In this article, we will explore the different types of contaminants that high flow filter cartridges can effectively remove, highlighting the importance of using these specialized filters in industrial settings.

One of the most common types of contaminants that high flow filter cartridges can remove is particulate matter. Particulate matter refers to solid particles suspended in a liquid or gas, such as dirt, rust, scale, and other debris. These particles can cause damage to equipment, clog pipelines, and affect the quality of the end product. High flow filter cartridges are designed with a high dirt-holding capacity, allowing them to capture and retain a large amount of particulate matter before needing to be replaced.

In addition to particulate matter, high flow filter cartridges are also effective at removing microorganisms and bacteria from liquids. In industries such as food and beverage, pharmaceuticals, and biotechnology, maintaining a sterile environment is crucial to prevent contamination and ensure product quality. High flow filter cartridges with a fine micron rating can effectively remove microorganisms and bacteria, helping to meet stringent regulatory requirements and industry standards.

Another type of contaminant that high flow filter cartridges can remove is oil and grease. In industrial processes where oils and lubricants are used, it is important to remove any traces of oil and grease from the fluid stream to prevent equipment damage and maintain product purity. High flow filter cartridges with specialized media can efficiently adsorb and trap oil and grease particles, ensuring that the filtered fluid meets the required cleanliness standards.

Chemical contaminants are also a common concern in industrial filtration applications. High flow filter cartridges are available with different types of media that are specifically designed to remove specific chemicals and contaminants from liquids and gases. Whether it is removing chlorine, heavy metals, or organic compounds, high flow filter cartridges can be customized to meet the unique filtration requirements of different industries.

In conclusion, high flow filter cartridges play a crucial role in optimizing industrial filtration systems by effectively removing various types of contaminants from liquids and gases. From particulate matter and microorganisms to oil and grease, these specialized filters are designed to handle high flow rates and provide reliable filtration performance. By choosing the right high flow filter cartridges for specific applications, industries can ensure the cleanliness, purity, and efficiency of their processes. Whether it is improving product quality, protecting equipment, or meeting regulatory requirements, high flow filter cartridges are an essential component of any industrial filtration system.

Cost Savings Associated with High Flow Filter Cartridges

High flow filter cartridges are an essential component of industrial filtration systems, playing a crucial role in removing contaminants from liquids and gases. These filter cartridges are designed to handle high flow rates, making them ideal for applications where large volumes of fluid need to be filtered quickly and efficiently. One of the key benefits of using high flow filter cartridges is the cost savings they can provide to industrial operations.

When it comes to industrial filtration systems, efficiency is key. High flow filter cartridges are designed to handle higher flow rates than traditional filter cartridges, allowing for faster filtration of fluids. This increased flow rate means that industrial processes can be completed more quickly, leading to higher productivity and reduced downtime. By optimizing the filtration process, high flow filter cartridges can help industrial operations save time and money.

In addition to increased efficiency, high flow filter cartridges can also lead to cost savings by reducing the need for frequent filter cartridge replacements. Traditional filter cartridges often need to be replaced frequently, especially in high-flow applications where they can become clogged with contaminants quickly. This frequent replacement can be costly, both in terms of the cost of the filter cartridges themselves and the labor required to replace them.

High flow filter cartridges, on the other hand, are designed to handle higher flow rates without becoming clogged as quickly. This means that they can last longer between replacements, reducing the overall cost of filtration for industrial operations. By using high flow filter cartridges, industrial operations can save money on filter cartridge replacements and reduce the amount of downtime required for maintenance.

Another cost-saving benefit of high flow filter cartridges is their compatibility with a wide range of industrial filtration systems. These filter cartridges can be easily integrated into existing filtration systems, making them a cost-effective solution for upgrading filtration processes. By simply replacing traditional filter cartridges with high flow filter cartridges, industrial operations can improve the efficiency of their filtration systems without the need for costly system upgrades.

Furthermore, high flow filter cartridges are designed to be more durable than traditional filter cartridges, reducing the risk of damage and the need for frequent replacements. This durability can lead to long-term cost savings for industrial operations, as the filter cartridges will last longer and require less maintenance over time. By investing in high flow filter cartridges, industrial operations can reduce their overall filtration costs and improve the reliability of their filtration systems.

In conclusion, high flow filter cartridges offer a cost-effective solution for optimizing industrial filtration systems. By increasing efficiency, reducing the need for frequent replacements, and improving durability, these filter cartridges can help industrial operations save money and improve the performance of their filtration processes. With their compatibility with a wide range of filtration systems, high flow filter cartridges are a versatile and cost-saving option for industrial applications.

Maintenance Tips for High Flow Filter Cartridges in Industrial Filtration Systems

How High Flow Filter Cartridges Optimize Industrial Filtration Systems

Industrial filtration systems play a crucial role in maintaining the efficiency and productivity of various manufacturing processes. These systems are responsible for removing contaminants and impurities from liquids and gases, ensuring that the final product meets the required quality standards. One key component of these filtration systems is the high flow filter cartridge, which is designed to handle large volumes of fluid while maintaining optimal filtration performance.

High flow filter cartridges are specifically engineered to handle high flow rates, making them ideal for industrial applications where large quantities of fluid need to be processed within a short period. These cartridges are typically made from durable materials such as polypropylene or stainless steel, ensuring their longevity and resistance to harsh operating conditions. The design of high flow filter cartridges allows for a larger surface area, which enhances their filtration capacity and efficiency.

One of the main advantages of using high flow filter cartridges in industrial filtration systems is their ability to optimize the overall system performance. By efficiently removing contaminants from the fluid, these cartridges help prevent clogging and fouling of downstream equipment, such as pumps, valves, and heat exchangers. This not only reduces maintenance and downtime but also extends the lifespan of the entire system, resulting in significant cost savings for the industrial facility.

To ensure that high flow filter cartridges continue to operate at their peak performance, regular maintenance is essential. Here are some maintenance tips to keep in mind:

1. Regular Inspection: It is important to visually inspect the filter cartridges on a regular basis to check for any signs of damage or wear. This includes checking for cracks, tears, or deformities that may affect their filtration efficiency. Any damaged cartridges should be replaced immediately to avoid compromising the overall system performance.

2. Cleaning: High flow filter cartridges can accumulate debris and contaminants over time, reducing their filtration capacity. Regular cleaning is necessary to remove these impurities and restore the cartridges’ efficiency. Depending on the type of contaminants and the filtration system, cleaning can be done through backwashing, chemical cleaning, or mechanical cleaning methods.

3. Replacement Schedule: High flow filter cartridges have a limited lifespan, and it is important to establish a replacement schedule based on the manufacturer’s recommendations and the specific operating conditions of the filtration system. Regularly replacing the cartridges ensures that the system continues to operate at its optimal performance and prevents any potential issues caused by worn-out cartridges.

4. Pressure Differential Monitoring: Monitoring the pressure differential across the high flow filter cartridges is crucial in determining their condition and performance. A sudden increase in pressure drop may indicate a clogged or fouled cartridge, requiring immediate attention. By regularly monitoring the pressure differential, maintenance personnel can take proactive measures to prevent any potential system failures.

In conclusion, high flow filter cartridges are essential components of industrial filtration systems, optimizing their performance and ensuring the quality of the final product. Regular maintenance, including inspection, cleaning, and replacement, is necessary to keep these cartridges operating at their peak efficiency. By following these maintenance tips, industrial facilities can maximize the lifespan of their filtration systems and minimize downtime, resulting in improved productivity and cost savings.