How Industrial Spiral Filter Belts Improve Process Efficiency

Increased Filtration Capacity

Industrial spiral filter belts are an essential component in many manufacturing processes, particularly in industries that require solid-liquid separation. These belts are designed to efficiently filter out impurities and contaminants from liquids, allowing for a cleaner and more refined end product. One of the key benefits of using industrial spiral filter belts is their ability to increase filtration capacity, ultimately improving process efficiency.

By utilizing industrial spiral filter belts, manufacturers can significantly enhance their filtration capabilities. These belts are specifically engineered to maximize surface area, allowing for a greater volume of liquid to pass through the filter at any given time. This increased filtration capacity means that more impurities can be removed from the liquid in a shorter amount of time, leading to faster processing times and higher throughput.

In addition to their enhanced filtration capacity, industrial spiral filter belts also offer improved efficiency in terms of maintenance and cleaning. These belts are constructed from durable materials that are resistant to wear and tear, making them ideal for continuous use in demanding industrial environments. Furthermore, the design of spiral filter belts allows for easy cleaning and maintenance, reducing downtime and ensuring that the filtration system operates at peak performance.

Another advantage of industrial spiral filter belts is their versatility and adaptability to a wide range of applications. These belts can be customized to meet the specific requirements of different industries, allowing manufacturers to achieve optimal filtration results for their unique processes. Whether filtering out solids from wastewater in the food and beverage industry or separating contaminants from chemicals in the pharmaceutical sector, industrial spiral filter belts can be tailored to deliver the desired filtration efficiency.

Furthermore, industrial spiral filter belts are designed to withstand high temperatures and harsh chemicals, making them suitable for use in a variety of industrial settings. This durability and resilience ensure that the filtration system remains operational even in the most challenging conditions, providing consistent and reliable performance over time.

In conclusion, industrial spiral filter belts play a crucial role in improving process efficiency by increasing filtration capacity. These belts offer a range of benefits, including enhanced surface area for greater liquid throughput, easy maintenance and cleaning, versatility for different applications, and durability in demanding environments. By incorporating industrial spiral filter belts into their filtration systems, manufacturers can achieve higher throughput, faster processing times, and cleaner end products. Ultimately, industrial spiral filter belts are a valuable investment for any industry that requires efficient solid-liquid separation.

Enhanced Productivity

Industrial spiral filter belts are an essential component in many manufacturing processes, particularly in industries such as food processing, chemical production, and wastewater treatment. These belts play a crucial role in separating solids from liquids, dewatering sludge, and filtering out impurities. By using industrial spiral filter belts, companies can improve their process efficiency, reduce downtime, and ultimately enhance productivity.

One of the key benefits of industrial spiral filter belts is their ability to handle high volumes of material while maintaining a consistent level of filtration. These belts are designed to withstand the rigors of continuous operation, making them ideal for use in demanding industrial environments. By using industrial spiral filter belts, companies can ensure that their filtration systems operate at peak efficiency, resulting in higher throughput and reduced processing times.

In addition to their durability, industrial spiral filter belts are also highly versatile. These belts can be customized to meet the specific needs of different industries, allowing companies to achieve optimal filtration results. Whether it’s removing solids from wastewater, separating ingredients in food processing, or dewatering sludge in a chemical plant, industrial spiral filter belts can be tailored to deliver the desired outcome.

Furthermore, industrial spiral filter belts are easy to install and maintain, making them a cost-effective solution for companies looking to improve their process efficiency. These belts are designed to be user-friendly, with simple installation procedures and minimal maintenance requirements. By using industrial spiral filter belts, companies can reduce the need for costly repairs and downtime, resulting in significant cost savings over time.

Another advantage of industrial spiral filter belts is their ability to improve product quality. By effectively separating solids from liquids and removing impurities, these belts help companies produce cleaner, purer products. This not only enhances the overall quality of the end product but also reduces the risk of contamination and ensures compliance with industry regulations.

Moreover, industrial spiral filter belts can help companies reduce their environmental footprint. By efficiently filtering out impurities and dewatering sludge, these belts can minimize waste and lower energy consumption. This not only benefits the environment but also helps companies reduce their operating costs and improve their sustainability efforts.

In conclusion, industrial spiral filter belts are a valuable tool for companies looking to enhance their process efficiency and productivity. These belts offer a range of benefits, including high durability, versatility, ease of installation and maintenance, improved product quality, and environmental sustainability. By incorporating industrial spiral filter belts into their filtration systems, companies can achieve higher throughput, reduced processing times, and cost savings. Ultimately, industrial spiral filter belts are a smart investment for companies looking to optimize their manufacturing processes and stay ahead of the competition.

Reduced Maintenance Costs

Industrial spiral filter belts are an essential component in many manufacturing processes, particularly in industries such as food processing, wastewater treatment, and chemical production. These belts play a crucial role in separating solids from liquids, dewatering sludge, and filtering out impurities. One of the key benefits of using industrial spiral filter belts is their ability to improve process efficiency, ultimately leading to reduced maintenance costs for businesses.

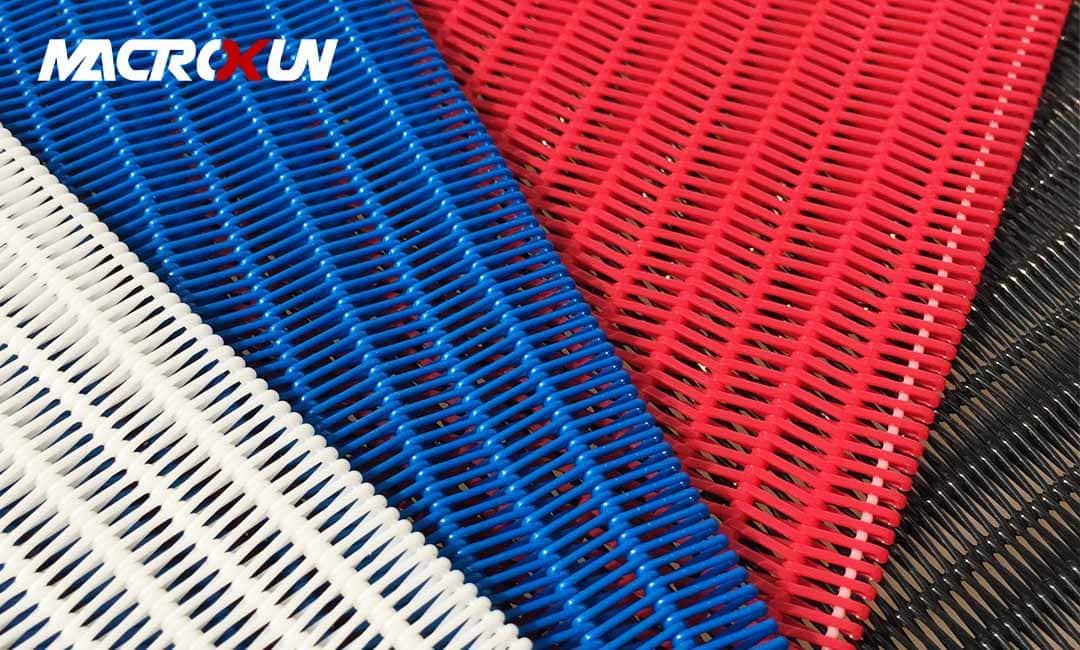

One way in which industrial spiral filter belts contribute to improved process efficiency is by enhancing the filtration process. These belts are designed with a spiral weave pattern that allows for maximum filtration surface area, ensuring that solids are effectively separated from liquids. This increased filtration efficiency results in cleaner filtrate and reduced downtime for maintenance and cleaning.

Furthermore, industrial spiral filter belts are highly durable and resistant to wear and tear. This durability is essential in industries where the filtration process is continuous and demanding. By using high-quality spiral filter belts, businesses can reduce the frequency of belt replacements and maintenance, ultimately saving time and money in the long run.

In addition to their durability, industrial spiral filter belts are also easy to clean and maintain. The spiral weave design allows for easy access to the belt surface, making it simple to remove debris and contaminants. This ease of maintenance not only reduces downtime for cleaning but also ensures that the filtration process remains efficient and effective.

Another way in which industrial spiral filter belts improve process efficiency is by reducing the risk of belt slippage and misalignment. The spiral weave pattern provides a stable and uniform surface for filtration, preventing the belt from slipping or becoming misaligned during operation. This stability ensures consistent filtration performance and minimizes the need for adjustments and realignments, further reducing maintenance costs for businesses.

Furthermore, industrial spiral filter belts are designed to withstand high temperatures and harsh chemicals, making them suitable for a wide range of industrial applications. Whether used in food processing, wastewater treatment, or chemical production, these belts can withstand the rigors of the manufacturing process without compromising on performance. This versatility and resilience make industrial spiral filter belts a cost-effective solution for businesses looking to improve process efficiency and reduce maintenance costs.

In conclusion, industrial spiral filter belts are a valuable asset for businesses seeking to enhance their manufacturing processes. By improving filtration efficiency, reducing maintenance costs, and ensuring durability and reliability, these belts play a crucial role in optimizing process performance. Businesses that invest in high-quality industrial spiral filter belts can expect to see significant improvements in their operations, ultimately leading to increased productivity and cost savings in the long term.