How Polyester Belts Improve Performance in Drying Machines

Enhanced Moisture Removal Efficiency

Polyester belts have emerged as a significant innovation in the realm of drying machines, particularly in enhancing moisture removal efficiency. The drying process is critical in various industries, including textiles, food processing, and pharmaceuticals, where the removal of moisture is essential for product quality and longevity. Traditional drying methods often struggle with achieving optimal moisture levels, leading to inefficiencies and increased energy consumption. However, the introduction of polyester belts has revolutionized this aspect of drying technology.

One of the primary advantages of polyester belts is their unique material properties, which contribute to superior moisture removal. Polyester is known for its high tensile strength and durability, allowing it to withstand the rigors of continuous operation in drying machines. This resilience ensures that the belts maintain their structural integrity over time, providing consistent performance. Moreover, polyester’s inherent moisture-wicking capabilities facilitate the rapid absorption and evaporation of moisture from the materials being dried. This characteristic is particularly beneficial in applications where quick drying is essential, as it significantly reduces drying times and enhances overall efficiency.

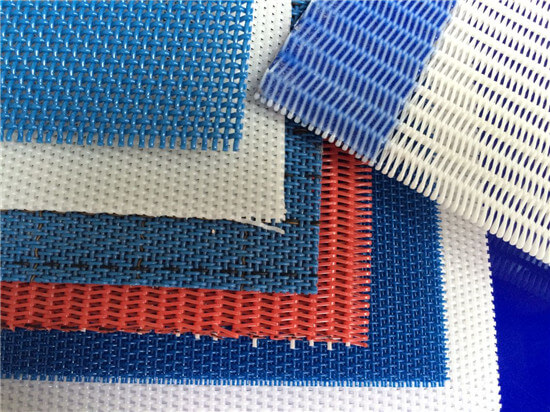

In addition to their moisture-wicking properties, polyester belts also promote better airflow within drying machines. The design of these belts often incorporates a porous structure, which allows for improved air circulation. Enhanced airflow is crucial in the drying process, as it aids in the removal of moisture-laden air and facilitates the introduction of fresh, dry air. This continuous exchange of air not only accelerates the drying process but also helps maintain consistent temperature levels throughout the drying chamber. As a result, products are dried more uniformly, reducing the risk of over-drying or under-drying, which can compromise quality.

Furthermore, the use of polyester belts can lead to significant energy savings. Traditional drying methods often require excessive heat and prolonged drying times, resulting in high energy consumption. In contrast, the efficiency of polyester belts allows for lower operating temperatures and shorter drying cycles. This reduction in energy usage not only lowers operational costs but also contributes to a more sustainable drying process. Industries are increasingly recognizing the importance of energy efficiency, and the adoption of polyester belts aligns with broader environmental goals by minimizing the carbon footprint associated with drying operations.

Another noteworthy aspect of polyester belts is their versatility. They can be tailored to meet the specific needs of various applications, whether in food processing, textile manufacturing, or other sectors. This adaptability ensures that businesses can optimize their drying processes according to the unique characteristics of the materials they handle. For instance, different belt designs can be employed to accommodate varying thicknesses and moisture content levels, further enhancing the efficiency of moisture removal.

In conclusion, polyester belts represent a significant advancement in drying technology, particularly in enhancing moisture removal efficiency. Their unique material properties, combined with improved airflow and energy-saving capabilities, make them an ideal choice for industries reliant on effective drying processes. As businesses continue to seek ways to improve operational efficiency and reduce costs, the adoption of polyester belts in drying machines is likely to become increasingly prevalent. This shift not only promises enhanced performance but also aligns with the growing emphasis on sustainability in industrial practices. Ultimately, the integration of polyester belts into drying systems marks a pivotal step toward achieving optimal moisture removal and operational excellence.

Durability and Longevity of Polyester Belts

Polyester belts have become increasingly popular in the realm of drying machines, primarily due to their remarkable durability and longevity. These belts are engineered to withstand the rigors of continuous operation, making them an ideal choice for industrial applications where reliability is paramount. The inherent properties of polyester contribute significantly to the performance of drying machines, ensuring that they operate efficiently over extended periods.

One of the key factors that enhance the durability of polyester belts is their resistance to wear and tear. Unlike traditional materials, polyester exhibits a high tensile strength, which allows it to endure the mechanical stresses associated with the drying process. This strength is particularly beneficial in environments where belts are subjected to constant friction and movement. As a result, polyester belts can maintain their structural integrity even under challenging conditions, reducing the frequency of replacements and minimizing downtime in production.

Moreover, polyester is inherently resistant to moisture and chemicals, which further extends the lifespan of these belts. In drying machines, where exposure to heat and humidity is commonplace, the ability of polyester to resist degradation from these elements is crucial. This moisture resistance not only prevents the belts from becoming brittle or warped but also ensures that they do not absorb water, which could lead to mold or mildew growth. Consequently, the longevity of polyester belts translates into lower maintenance costs and improved operational efficiency.

In addition to their physical properties, the manufacturing process of polyester belts also plays a significant role in their durability. Advanced weaving techniques and the use of high-quality fibers result in belts that are not only strong but also flexible. This flexibility allows the belts to adapt to the movements of the drying machine without compromising their performance. As a result, they can effectively handle varying loads and speeds, which is essential for maintaining consistent drying results.

Furthermore, the longevity of polyester belts is enhanced by their ability to withstand temperature fluctuations. Drying machines often operate at elevated temperatures, and materials that cannot tolerate such conditions may fail prematurely. Polyester belts, however, are designed to endure high temperatures without losing their mechanical properties. This thermal stability ensures that the belts continue to perform optimally, even in the most demanding drying environments.

Another aspect worth noting is the environmental impact of polyester belts. Their durability means that fewer belts are needed over time, which reduces waste and contributes to more sustainable industrial practices. By choosing polyester belts, manufacturers can not only improve their operational efficiency but also align with eco-friendly initiatives aimed at reducing material consumption and waste generation.

In conclusion, the durability and longevity of polyester belts make them an invaluable component in the operation of drying machines. Their resistance to wear, moisture, and temperature fluctuations ensures that they can withstand the demands of continuous use, ultimately leading to enhanced performance and reduced maintenance costs. As industries continue to seek reliable and efficient solutions, polyester belts stand out as a superior choice, offering both performance and sustainability in the ever-evolving landscape of industrial drying processes.

Cost-Effectiveness and Energy Savings in Drying Processes

Polyester belts have emerged as a pivotal component in the realm of drying machines, particularly due to their cost-effectiveness and energy-saving capabilities. As industries increasingly seek ways to optimize their operations, the choice of materials used in machinery becomes crucial. Polyester, known for its durability and resilience, offers significant advantages that contribute to both economic and environmental sustainability.

One of the primary benefits of polyester belts is their ability to withstand high temperatures and resist wear and tear. This durability translates into longer service life, reducing the frequency of replacements and maintenance. Consequently, businesses can save on operational costs associated with downtime and repairs. The initial investment in polyester belts may be slightly higher than that of other materials; however, the long-term savings realized through reduced maintenance and replacement costs often outweigh this initial expenditure.

Moreover, polyester belts are designed to operate efficiently under various conditions, which is essential in drying processes where moisture levels can fluctuate. Their ability to maintain consistent performance ensures that drying machines operate at optimal levels, thereby enhancing productivity. When machines run efficiently, they consume less energy, leading to significant savings on utility bills. This energy efficiency is particularly important in industries where drying processes are integral to production, such as textiles, food processing, and pharmaceuticals.

In addition to their energy-saving properties, polyester belts contribute to a more sustainable production process. As companies face increasing pressure to reduce their carbon footprint, the use of energy-efficient machinery becomes a priority. By incorporating polyester belts into their drying machines, businesses can not only lower their energy consumption but also minimize their environmental impact. This alignment with sustainability goals can enhance a company’s reputation and appeal to environmentally conscious consumers, further driving demand for their products.

Furthermore, the lightweight nature of polyester belts allows for easier handling and installation, which can streamline the setup process for drying machines. This ease of use can lead to reduced labor costs and faster turnaround times, enabling companies to respond more swiftly to market demands. As industries strive for agility in their operations, the adaptability of polyester belts becomes an invaluable asset.

Transitioning to the operational aspects, the performance of polyester belts in drying machines is often reflected in the quality of the final product. Consistent drying results in fewer defects and higher quality outputs, which can significantly impact customer satisfaction and brand loyalty. In competitive markets, the ability to deliver superior products can set a company apart from its rivals, making the investment in polyester belts a strategic decision.

In conclusion, the integration of polyester belts into drying machines offers a multitude of benefits that extend beyond mere cost savings. Their durability, energy efficiency, and contribution to sustainable practices make them an ideal choice for industries reliant on drying processes. As businesses continue to seek ways to enhance their operational efficiency and reduce costs, polyester belts stand out as a practical solution that not only improves performance but also aligns with broader economic and environmental objectives. By investing in this innovative technology, companies can ensure they remain competitive in an ever-evolving marketplace while also contributing positively to the planet.