How Polyester Mesh Belts Ensure Uniform Drying in Industrial Processes

Benefits of Using Polyester Mesh Belts for Drying Applications

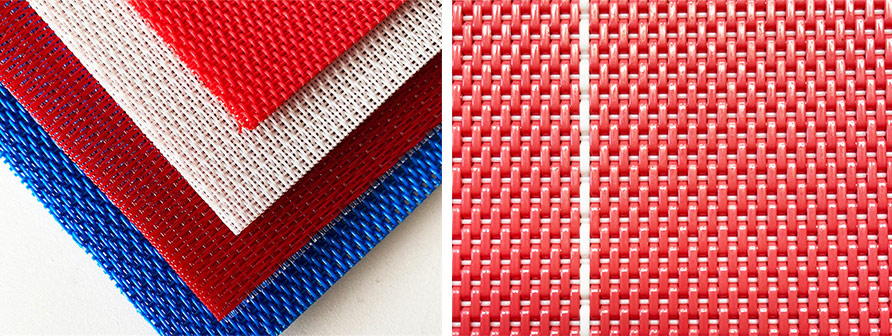

Polyester mesh belts have become increasingly popular in various industrial drying applications due to their unique properties and advantages. One of the primary benefits of using polyester mesh belts is their ability to provide uniform drying across a wide range of materials. This uniformity is crucial in industrial processes where consistency in product quality is paramount. The open structure of polyester mesh allows for optimal airflow, which facilitates even heat distribution and moisture removal. As a result, products dried on these belts experience reduced drying times, leading to increased efficiency in production lines.

In addition to promoting uniform drying, polyester mesh belts are also highly durable and resistant to wear and tear. This durability is essential in industrial settings where equipment is subjected to continuous use and harsh conditions. Polyester, as a material, exhibits excellent resistance to chemicals and high temperatures, making it suitable for various drying applications, including those involving solvents or aggressive substances. The longevity of polyester mesh belts translates to lower maintenance costs and reduced downtime, which are critical factors in maintaining productivity in industrial operations.

Another significant advantage of polyester mesh belts is their lightweight nature, which contributes to easier handling and installation. This characteristic is particularly beneficial in large-scale operations where heavy equipment can complicate maintenance and adjustments. The lightweight design of polyester mesh belts allows for quick replacements and modifications, ensuring that production processes can resume with minimal interruption. Furthermore, the flexibility of these belts enables them to conform to different drying systems, making them versatile for various applications, from food processing to textile manufacturing.

Moreover, polyester mesh belts are designed to be easy to clean, which is an essential feature in industries where hygiene is a priority. The open mesh structure minimizes the accumulation of residues and contaminants, allowing for efficient cleaning processes. This ease of maintenance not only helps in adhering to strict hygiene standards but also contributes to the overall efficiency of the drying process. By ensuring that the belts remain clean, manufacturers can prevent cross-contamination and maintain the integrity of their products.

In terms of energy efficiency, polyester mesh belts play a vital role in reducing operational costs. The enhanced airflow and moisture removal capabilities of these belts allow for lower energy consumption during the drying process. As industries increasingly focus on sustainability and reducing their carbon footprint, the energy-efficient nature of polyester mesh belts aligns with these goals. By optimizing drying times and minimizing energy usage, companies can achieve significant cost savings while also contributing to environmental conservation.

Furthermore, the adaptability of polyester mesh belts to various drying technologies, such as conveyor dryers and infrared dryers, enhances their appeal in industrial applications. This adaptability ensures that manufacturers can integrate polyester mesh belts into their existing systems without the need for extensive modifications. As a result, businesses can leverage the benefits of polyester mesh belts without incurring significant additional costs or disruptions to their operations.

In conclusion, the benefits of using polyester mesh belts for drying applications are manifold. Their ability to ensure uniform drying, coupled with durability, lightweight design, ease of cleaning, energy efficiency, and adaptability to various systems, makes them an ideal choice for industries seeking to enhance their drying processes. As manufacturers continue to prioritize efficiency and product quality, polyester mesh belts will undoubtedly remain a critical component in achieving these objectives.

How Polyester Mesh Belts Improve Airflow and Heat Distribution for Uniform Drying

Polyester mesh belts play a crucial role in ensuring uniform drying in various industrial processes. These belts are designed to improve airflow and heat distribution, which are essential for achieving consistent drying results. By understanding how polyester mesh belts work and their benefits, industries can optimize their drying processes and enhance overall efficiency.

One of the key advantages of polyester mesh belts is their ability to improve airflow. The open mesh design of these belts allows air to circulate freely throughout the drying chamber, ensuring that all parts of the product being dried receive equal exposure to heat. This helps prevent uneven drying and ensures that the product is dried thoroughly and evenly.

In addition to improving airflow, polyester mesh belts also enhance heat distribution. The mesh material of these belts is heat-resistant, allowing them to withstand high temperatures without warping or melting. This ensures that heat is evenly distributed across the entire surface of the belt, preventing hot spots and ensuring that the product is dried uniformly.

Furthermore, polyester mesh belts are highly durable and long-lasting, making them ideal for use in industrial drying processes. These belts can withstand heavy loads and high temperatures, making them suitable for a wide range of applications. Their durability also means that they require minimal maintenance, reducing downtime and increasing overall productivity.

Another benefit of polyester mesh belts is their versatility. These belts can be customized to meet the specific requirements of different drying processes, making them suitable for a wide range of industries. Whether drying food products, textiles, or chemicals, polyester mesh belts can be tailored to ensure optimal drying results.

Moreover, polyester mesh belts are easy to clean and sanitize, making them ideal for industries that require strict hygiene standards. The open mesh design of these belts allows for easy access to the surface, making it simple to remove any debris or contaminants that may accumulate during the drying process. This helps prevent cross-contamination and ensures that the product remains safe for consumption or use.

In conclusion, polyester mesh belts are essential for ensuring uniform drying in industrial processes. Their ability to improve airflow and heat distribution, along with their durability, versatility, and ease of cleaning, make them an ideal choice for a wide range of applications. By investing in high-quality polyester mesh belts, industries can optimize their drying processes, improve efficiency, and achieve consistent drying results.

Case Studies Demonstrating the Efficiency of Polyester Mesh Belts in Industrial Drying Processes

Polyester mesh belts have become a popular choice in industrial drying processes due to their ability to ensure uniform drying of materials. These belts are made from high-quality polyester fibers that are woven together to create a strong and durable mesh structure. This allows for efficient air flow and heat transfer, resulting in consistent drying across the entire surface of the material being processed.

One of the key advantages of using polyester mesh belts in industrial drying processes is their ability to provide a large surface area for the material to be spread out evenly. This helps to prevent clumping and ensures that all parts of the material are exposed to the same drying conditions. As a result, the material dries more quickly and evenly, leading to higher quality end products.

In a recent case study, a manufacturer of food products was able to significantly improve their drying process by switching to polyester mesh belts. Prior to using these belts, the company was experiencing uneven drying and inconsistent product quality. However, after implementing the new belts, they saw a dramatic improvement in the uniformity of their dried products. This not only increased the overall efficiency of their production process but also led to higher customer satisfaction due to the improved quality of their products.

Another case study involved a manufacturer of textiles who was struggling with uneven drying of their fabrics. By switching to polyester mesh belts, they were able to achieve a more consistent drying process, resulting in higher quality fabrics that met their customers’ specifications. The company also saw a reduction in production time and energy costs, as the improved drying efficiency allowed them to process more materials in less time.

Polyester mesh belts are also highly versatile and can be customized to meet the specific needs of different industries. Whether it’s food processing, textiles, or any other industrial application, these belts can be tailored to provide the optimal drying conditions for a wide range of materials. This flexibility makes them a valuable asset for companies looking to improve their drying processes and enhance the quality of their products.

In conclusion, polyester mesh belts are an essential tool for ensuring uniform drying in industrial processes. Their ability to provide a large surface area, efficient air flow, and customizable design make them a reliable and effective solution for a wide range of applications. By investing in these belts, companies can improve the efficiency of their drying processes, reduce production time and costs, and ultimately deliver higher quality products to their customers. With their proven track record of success in various industries, polyester mesh belts are a valuable asset for any company looking to optimize their drying processes and achieve consistent, high-quality results.