How to Choose the Right Micron Bags for Your Rosin Press

Importance of Choosing the Right Micron Bags

Choosing the right micron bags for your rosin press is crucial to the quality of your final product. The micron size of the bag determines the level of filtration during the extraction process. Different materials require different micron sizes to achieve the best results. By selecting the appropriate micron bags, you can ensure maximum yield and potency in your rosin extraction.

When deciding on the right micron bags for your rosin press, consider the type of material you are using. For example, if you are pressing kief or hash, a finer micron bag around 25-37 microns would be suitable to prevent any plant material from contaminating the extract. On the other hand, for flower rosin, a slightly larger micron size between 90-160 microns is preferred to allow the oil to flow more freely while still capturing the trichomes effectively.

Factors to Consider When Purchasing Micron Bags

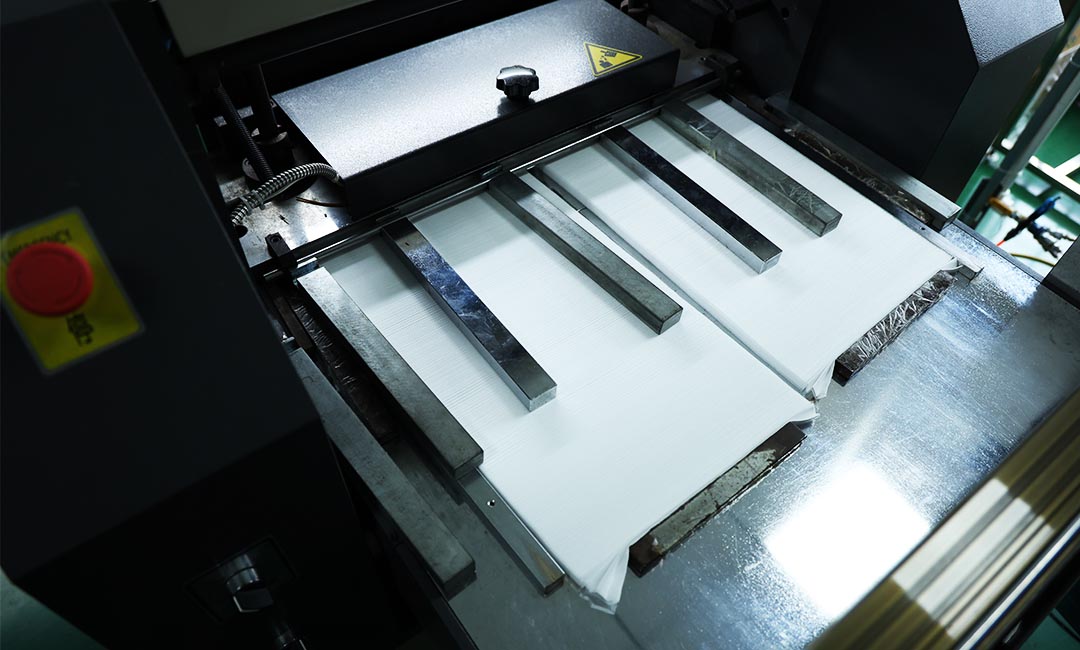

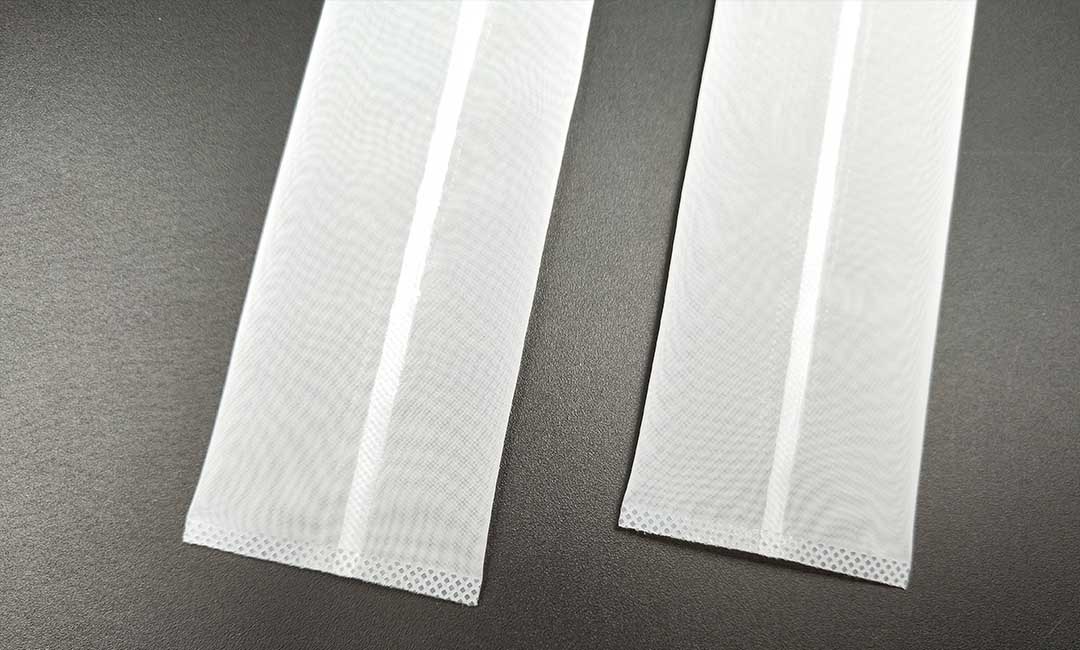

There are several factors to consider when purchasing micron bags for your rosin press. Firstly, ensure that the bags are made of high-quality, food-grade nylon material that can withstand heat and pressure during the extraction process. Additionally, check the stitching and seams of the bags to prevent blowouts and ensure durability over multiple uses.

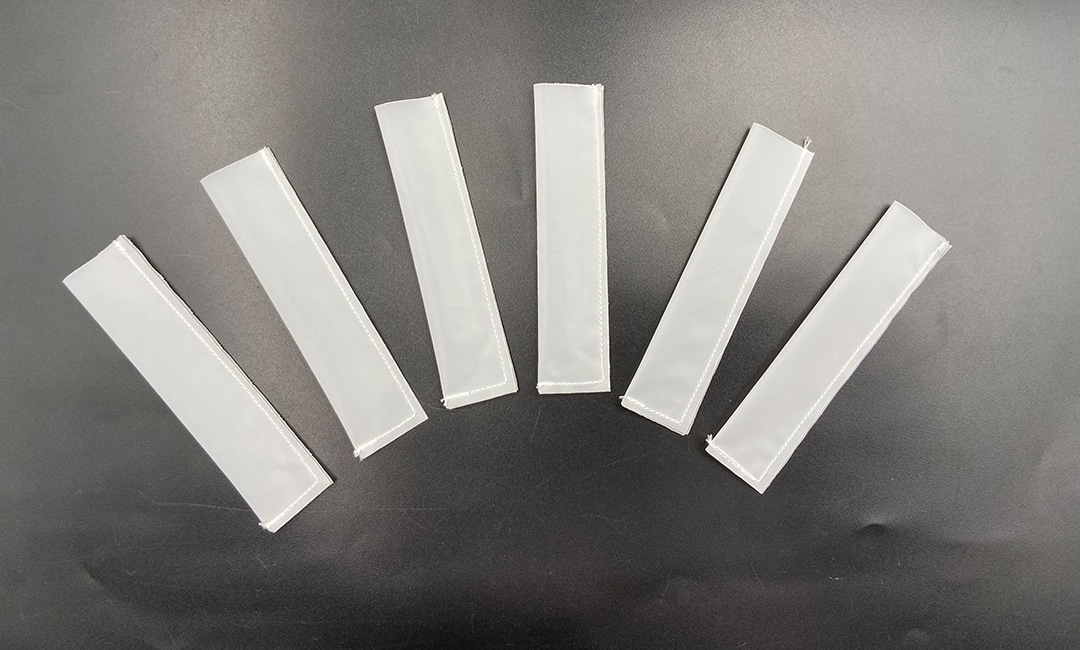

Another important factor to consider is the size of the bags. Make sure to choose bags that are compatible with the size of your rosin press plates to maximize efficiency and avoid wastage. It is recommended to have a variety of sizes on hand to accommodate different batch sizes and types of material for extraction.

Tips for Maintaining Micron Bags

Proper maintenance of your micron bags is essential to prolong their lifespan and maintain consistent extraction results. After each use, carefully clean the bags with warm water and mild soap to remove any residue or contaminants. Allow the bags to air dry completely before storing them in a cool, dry place to prevent mold or mildew growth.

Avoid overfilling the bags beyond their recommended capacity to prevent bursting during the pressing process. Regularly inspect the bags for any signs of wear and tear, such as holes or fraying, and replace them as needed to ensure optimal filtration and extraction efficiency.