How to Choose the Right Micron for Rosin Press Bags

Benefits of Using Different Micron Sizes for Rosin Press Bags

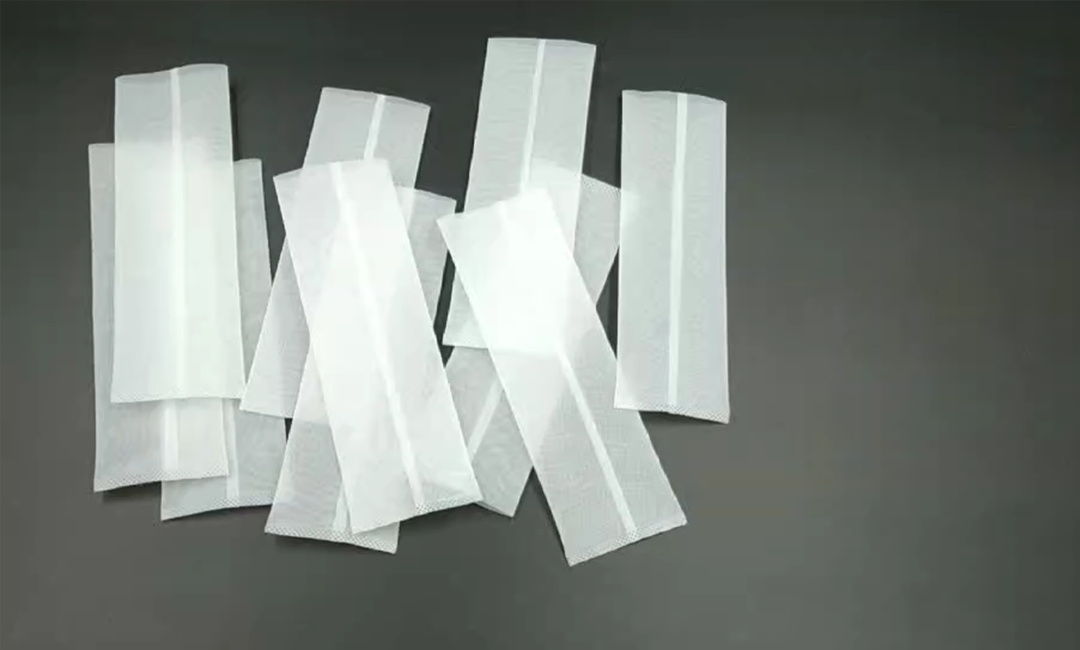

When it comes to making rosin, the quality of your rosin press bags can make a significant difference in the final product. Rosin press bags are essential for containing your material while allowing the rosin to flow out freely. One crucial factor to consider when choosing rosin press bags is the micron size. Micron size refers to the size of the openings in the bag, which determines the level of filtration and the quality of the rosin produced.

Different micron sizes are suitable for different types of material and desired outcomes. Understanding the benefits of using different micron sizes for rosin press bags can help you make an informed decision when selecting the right bags for your needs.

One of the most common micron sizes for rosin press bags is 90 microns. This size is ideal for pressing flower material, as it provides a good balance between yield and quality. The 90-micron bags allow for the extraction of a significant amount of rosin while still retaining the essential oils and terpenes that contribute to the flavor and aroma of the final product.

For those looking to produce a higher-quality rosin with a more refined taste and aroma, a lower micron size such as 37 or 45 microns may be more suitable. These smaller micron sizes provide a higher level of filtration, resulting in a cleaner and more potent rosin. While the yield may be slightly lower with these finer bags, the overall quality of the rosin is often worth the trade-off for many users.

On the other hand, if you are pressing material with a higher resin content, such as hash or kief, a larger micron size like 160 or 190 microns may be more appropriate. These larger micron sizes allow for easier extraction of the rosin without clogging the bags with excess material. The larger openings also help to prevent blowouts and ensure a smoother pressing process.

It is essential to consider the type of material you will be pressing and the desired outcome when choosing the right micron size for your rosin press bags. Experimenting with different micron sizes can help you determine which size works best for your specific needs and preferences.

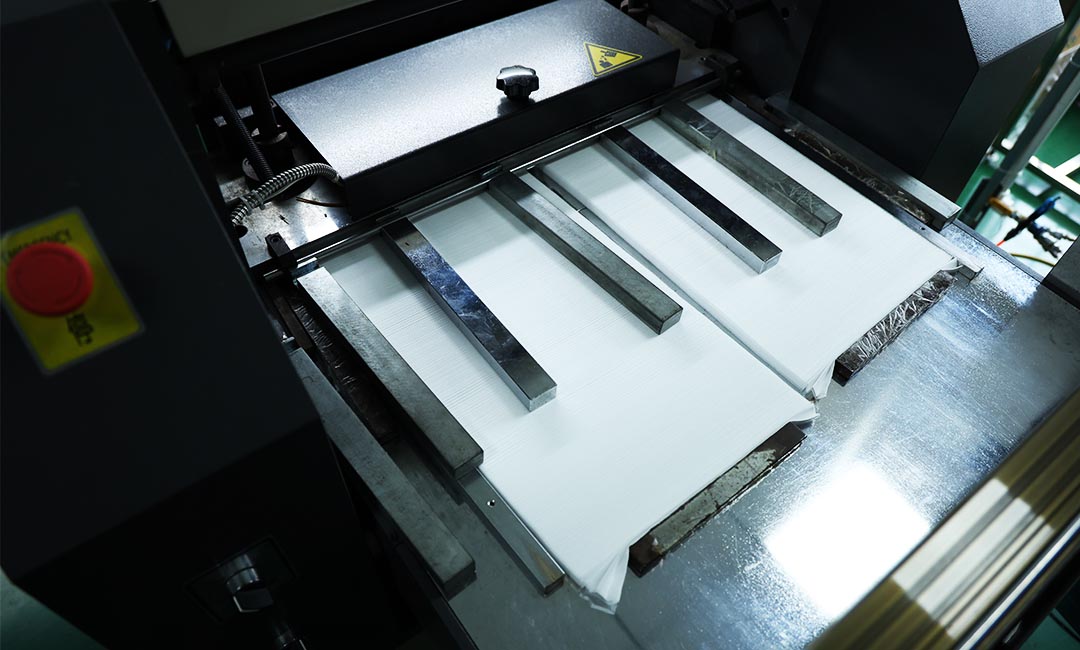

In addition to the micron size, other factors to consider when choosing rosin press bags include the material of the bags and the stitching quality. High-quality bags made from durable materials like nylon or polyester are essential for withstanding the pressure and heat of the pressing process. Bags with reinforced stitching are also crucial for preventing blowouts and ensuring a successful extraction.

Overall, selecting the right micron size for your rosin press bags is a critical step in producing high-quality rosin. By understanding the benefits of using different micron sizes and considering the type of material you will be pressing, you can make an informed decision that will help you achieve the best possible results. Experimenting with different micron sizes and refining your technique over time will ultimately lead to a more enjoyable and rewarding rosin pressing experience.

Factors to Consider When Selecting the Right Micron for Rosin Press Bags

When selecting the appropriate micron for rosin press bags, several critical factors must be considered to ensure optimal extraction and quality of the final product. The micron size refers to the diameter of the filter mesh used in the bags, which plays a pivotal role in determining the efficiency of the extraction process. One of the primary considerations is the type of material being processed. Different materials, such as flowers, hash, or kief, have varying levels of resin content and consistency. For instance, when working with flower, a micron size between 90 to 120 is often recommended, as it allows for a good balance between yield and purity. Conversely, when extracting from hash or kief, a finer micron, typically around 25 to 45, may be more suitable, as it can help capture the more delicate trichomes while filtering out unwanted plant material.

Another essential factor to consider is the desired end product. The clarity and quality of the rosin can be significantly influenced by the micron size chosen. A finer micron bag will yield a cleaner product with fewer impurities, which is particularly important for consumers seeking high-quality concentrates. However, it is crucial to note that using a micron that is too fine can lead to lower yields, as some of the desirable oils may be trapped within the bag. Therefore, striking the right balance between yield and purity is vital, and this often requires experimentation with different micron sizes to determine what works best for specific materials and desired outcomes.

In addition to the type of material and desired product quality, the pressing technique employed also plays a significant role in the selection of micron size. Different pressing methods, such as heat and pressure application, can affect how the resin is extracted from the plant material. For example, if using a lower temperature and pressure, a larger micron size may be more effective, as it allows for a more gentle extraction process. Conversely, higher temperatures and pressures may necessitate a finer micron to ensure that the extraction is efficient while still maintaining the integrity of the product. Understanding the interplay between pressing techniques and micron size can help in achieving the best results.

Moreover, the experience level of the extractor should not be overlooked when choosing the right micron for rosin press bags. Beginners may benefit from starting with a medium micron size, as it provides a good compromise between yield and purity, allowing for a more forgiving extraction process. As one gains experience and develops a better understanding of their materials and techniques, they can experiment with finer or coarser microns to refine their results further. This gradual approach not only enhances skill but also fosters a deeper appreciation for the nuances of the extraction process.

Lastly, it is essential to consider the quality of the rosin press bags themselves. High-quality bags made from durable materials will withstand the pressures of extraction without tearing or leaking, which can compromise the entire process. Investing in reputable brands that offer a range of micron sizes can provide the flexibility needed to adapt to different materials and extraction goals. In conclusion, selecting the right micron for rosin press bags involves a careful evaluation of the material type, desired product quality, pressing techniques, experience level, and bag quality. By thoughtfully considering these factors, one can optimize their extraction process and achieve superior results.

Comparison of Different Micron Sizes for Rosin Press Bags

When it comes to making rosin, the quality of your rosin press bags can make a significant difference in the final product. Rosin press bags are essential for containing your material while allowing the rosin to flow out freely. One of the most critical factors to consider when choosing rosin press bags is the micron size. The micron size of a rosin press bag refers to the size of the mesh openings in the bag. The smaller the micron size, the finer the mesh, and the more filtration the bag will provide.

There are several different micron sizes available for rosin press bags, ranging from 25 microns to 220 microns. Each micron size has its own unique benefits and is suitable for different types of material. Understanding the differences between these micron sizes can help you choose the right one for your specific needs.

Let’s start with the lower end of the spectrum – 25 micron bags. These bags are the finest mesh available and are ideal for pressing very high-quality material, such as bubble hash or kief. The small mesh size of 25 microns ensures that only the purest and cleanest rosin is extracted, with minimal plant material or contaminants. However, because of the fine mesh, 25 micron bags can be more prone to blowouts or clogging, so they require careful handling during the pressing process.

Moving up the scale, 37 micron bags are also suitable for high-quality material, such as sift or dry sift. These bags provide slightly more filtration than 25 micron bags, while still allowing for a clean and pure extraction. 37 micron bags are a good choice for those looking for a balance between purity and yield.

For those working with flower or trim, 90 micron bags are a popular choice. These bags offer a good balance between filtration and yield, allowing for a clean extraction while still capturing a decent amount of rosin. 90 micron bags are versatile and can be used with a wide range of materials, making them a popular choice among rosin enthusiasts.

If you’re looking to maximize your yield, 120 micron bags are a good option. These bags provide less filtration than 90 micron bags, allowing for a higher yield of rosin. While the quality of the extraction may not be as high as with finer mesh bags, 120 micron bags are a good choice for those looking to extract as much rosin as possible from their material.

Moving up to even larger micron sizes, 160 micron bags are suitable for lower-quality material, such as trim or shake. These bags offer minimal filtration, allowing for a higher yield of rosin, but with more plant material and contaminants present in the final product.

Finally, 220 micron bags are the largest mesh size available and are best suited for material that is not as finely ground, such as whole flower. These bags provide minimal filtration, resulting in a higher yield of rosin but with more impurities present in the final product.

In conclusion, choosing the right micron size for your rosin press bags depends on the type of material you are working with and the quality of the extraction you are looking to achieve. By understanding the differences between the various micron sizes available, you can select the best rosin press bags for your specific needs and produce high-quality rosin every time.

Tips for Choosing the Best Micron Size for Your Rosin Press Bags

When it comes to making rosin, choosing the right micron size for your rosin press bags is crucial. The micron size of your bags will determine the quality and yield of your rosin, so it’s important to choose wisely. In this article, we will discuss some tips for choosing the best micron size for your rosin press bags.

First and foremost, it’s important to understand what micron size means. Micron size refers to the size of the holes in the bag, which determines the size of the particles that can pass through. The lower the micron size, the smaller the holes in the bag, which means that only smaller particles will be able to pass through. This is important because the size of the particles that pass through the bag will affect the quality and yield of your rosin.

When choosing the right micron size for your rosin press bags, it’s important to consider the type of material you will be pressing. Different materials require different micron sizes to achieve the best results. For example, if you are pressing dry sift or kief, you will want to use a lower micron size, such as 25 or 37, to ensure that only the trichomes pass through the bag. On the other hand, if you are pressing flower, you may want to use a higher micron size, such as 90 or 120, to allow more material to pass through the bag.

Another factor to consider when choosing the right micron size for your rosin press bags is the pressure you will be applying during the pressing process. Higher pressure will require a lower micron size to prevent blowouts, while lower pressure may allow you to use a higher micron size. It’s important to experiment with different micron sizes and pressures to find the right combination for your specific needs.

In addition to considering the type of material and pressure you will be using, it’s also important to consider the quality of the bags themselves. Not all rosin press bags are created equal, and using low-quality bags can affect the quality and yield of your rosin. Look for bags that are made from high-quality materials and have a tight weave to ensure that they can withstand the pressure of the pressing process.

When choosing the right micron size for your rosin press bags, it’s important to remember that there is no one-size-fits-all solution. It may take some trial and error to find the right combination of micron size, pressure, and material for your specific needs. Don’t be afraid to experiment with different combinations to find what works best for you.

In conclusion, choosing the right micron size for your rosin press bags is crucial for achieving the best quality and yield of your rosin. Consider the type of material you will be pressing, the pressure you will be applying, and the quality of the bags themselves when making your decision. Remember that it may take some trial and error to find the right combination for your specific needs, so don’t be afraid to experiment. With the right micron size and technique, you can produce high-quality rosin every time.