How to Maintain and Clean High Flow Pleated Filters

Importance of Regular Cleaning and Maintenance for High Flow Pleated Filters

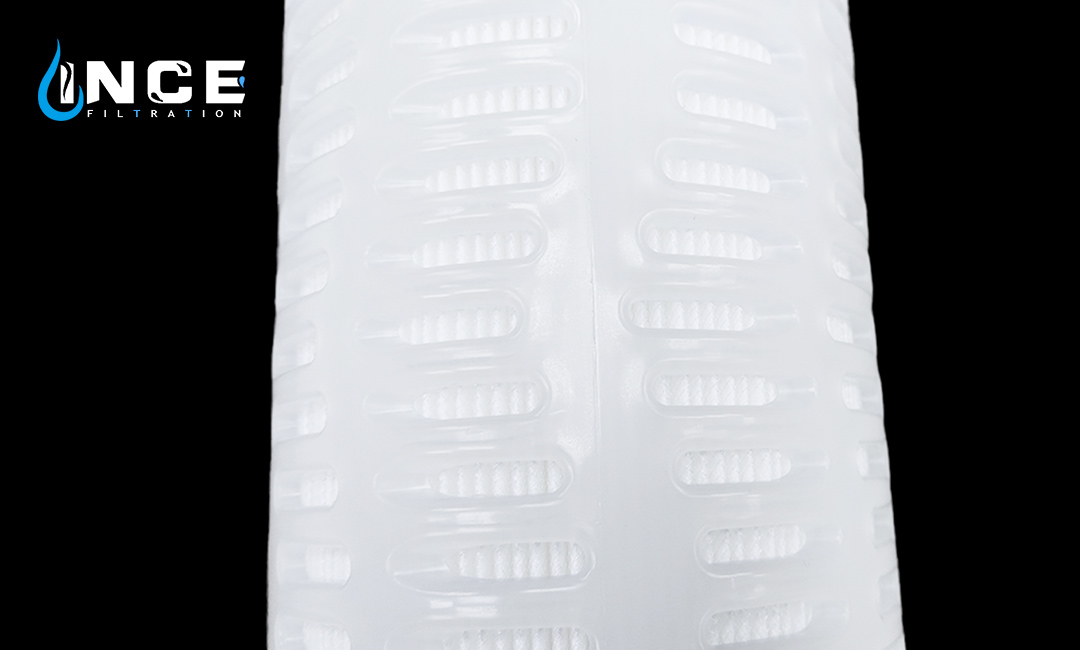

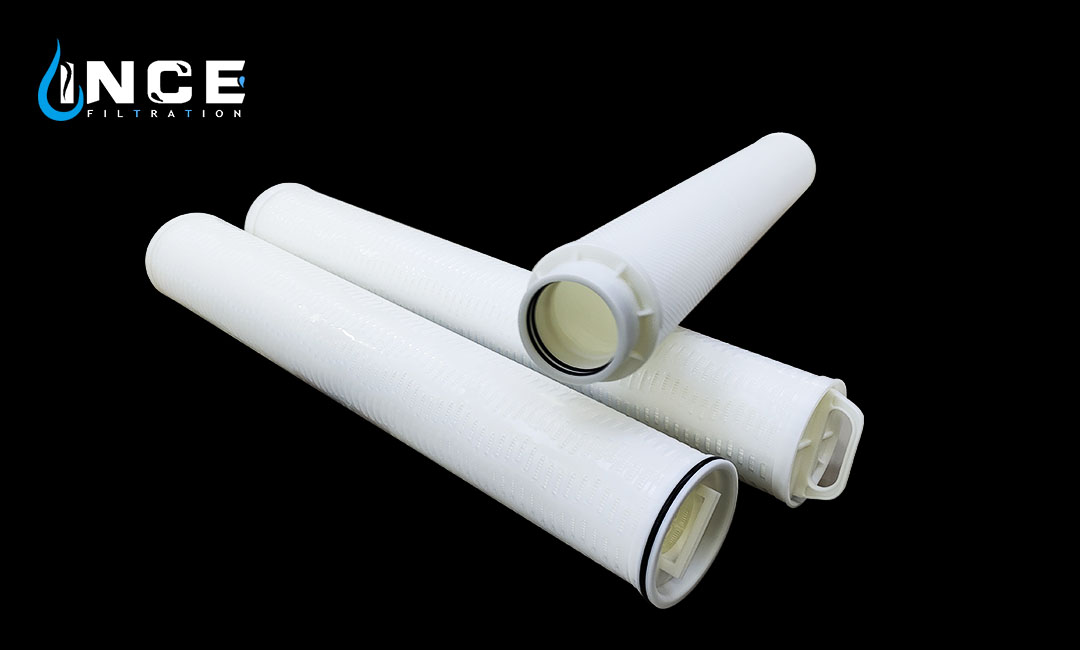

High flow pleated filters are an essential component in many industrial and commercial applications. These filters are designed to handle high flow rates while effectively removing contaminants from the air or liquid being filtered. However, in order for high flow pleated filters to continue operating at peak efficiency, regular cleaning and maintenance are crucial.

One of the main reasons why regular cleaning and maintenance of high flow pleated filters is so important is to ensure optimal performance. Over time, contaminants can build up on the surface of the filter, reducing its ability to effectively remove particles from the air or liquid passing through it. This can lead to decreased filtration efficiency and potentially damage to downstream equipment.

In addition to maintaining optimal performance, regular cleaning and maintenance of high flow pleated filters can also extend the lifespan of the filter itself. By removing built-up contaminants and debris, the filter can continue to operate at peak efficiency for a longer period of time. This can help to reduce the frequency of filter replacements, saving both time and money in the long run.

There are several key steps that should be taken to properly clean and maintain high flow pleated filters. The first step is to regularly inspect the filter for any signs of damage or wear. This can include tears or holes in the filter media, as well as any signs of clogging or blockages. If any damage is found, the filter should be replaced immediately to prevent further issues.

Once the filter has been inspected, it should be removed from the system and cleaned according to the manufacturer’s instructions. This may involve rinsing the filter with water or a cleaning solution to remove built-up contaminants. It is important to use caution when cleaning high flow pleated filters, as harsh chemicals or excessive force can damage the filter media and reduce its effectiveness.

After cleaning, the filter should be allowed to dry completely before being reinstalled in the system. It is important to ensure that the filter is properly seated and secured in place to prevent leaks or bypassing of contaminants. Regularly checking the filter for proper installation can help to prevent issues down the line.

In addition to regular cleaning and maintenance, it is also important to monitor the performance of high flow pleated filters over time. This can include measuring pressure differentials across the filter, as well as monitoring the quality of the air or liquid being filtered. Any changes in performance should be investigated and addressed promptly to prevent further issues.

In conclusion, regular cleaning and maintenance of high flow pleated filters is essential for ensuring optimal performance and extending the lifespan of the filter. By following the manufacturer’s instructions and monitoring the filter’s performance over time, you can help to keep your filtration system running smoothly and efficiently. Taking the time to properly care for your high flow pleated filters can help to prevent costly downtime and repairs in the future.

Step-by-Step Guide to Cleaning High Flow Pleated Filters

High flow pleated filters are an essential component of many industrial and commercial filtration systems. These filters are designed to handle high flow rates while still providing effective filtration of contaminants. However, like any filter, high flow pleated filters require regular maintenance and cleaning to ensure optimal performance. In this article, we will provide a step-by-step guide on how to properly maintain and clean high flow pleated filters.

The first step in maintaining high flow pleated filters is to regularly inspect them for any signs of damage or clogging. Inspecting the filters will allow you to identify any issues early on and address them before they become more serious. Look for tears, holes, or other damage to the filter material, as well as any buildup of contaminants that could be restricting flow.

Once you have inspected the filters, the next step is to remove them from the filtration system for cleaning. Most high flow pleated filters are designed to be easily removed and replaced, making this step relatively simple. Carefully follow the manufacturer’s instructions for removing the filters to avoid causing any damage.

After removing the filters, the next step is to clean them. Start by gently tapping the filters to dislodge any loose debris or contaminants. You can also use a soft brush or compressed air to help remove any stubborn buildup. Be careful not to damage the filter material during this process.

Once you have removed as much debris as possible, the next step is to wash the filters. Fill a clean bucket or sink with warm water and a mild detergent. Submerge the filters in the soapy water and gently agitate them to help loosen any remaining contaminants. Allow the filters to soak for a few minutes to ensure thorough cleaning.

After soaking, rinse the filters thoroughly with clean water to remove any soap residue. You can also use a hose or pressure washer to help remove stubborn contaminants. Be sure to rinse the filters from the clean side to the dirty side to avoid pushing contaminants back into the filter material.

Once the filters are clean, the next step is to allow them to dry completely before reinstalling them in the filtration system. You can air dry the filters or use a clean, lint-free cloth to gently pat them dry. Avoid using heat or direct sunlight to dry the filters, as this can damage the filter material.

Finally, once the filters are dry, carefully reinstall them in the filtration system following the manufacturer’s instructions. Be sure to secure the filters properly to prevent any leaks or bypass of contaminants. Once the filters are back in place, monitor their performance to ensure they are functioning properly.

In conclusion, maintaining and cleaning high flow pleated filters is essential for ensuring optimal filtration performance. By following the steps outlined in this guide, you can keep your filters in top condition and extend their lifespan. Regular inspection, gentle cleaning, and proper installation are key to keeping your high flow pleated filters operating efficiently.

Tips for Extending the Lifespan of High Flow Pleated Filters

High flow pleated filters are an essential component in many industrial and commercial applications. These filters are designed to handle high flow rates while effectively removing contaminants from liquids or gases. To ensure that high flow pleated filters continue to perform at their best, regular maintenance and cleaning are necessary. By following a few simple tips, you can extend the lifespan of your high flow pleated filters and maximize their efficiency.

One of the most important steps in maintaining high flow pleated filters is to regularly inspect them for any signs of damage or clogging. Over time, dirt, debris, and other contaminants can build up on the surface of the filter, reducing its effectiveness. By inspecting the filter regularly, you can identify any issues early on and take the necessary steps to address them before they become more serious.

When it comes to cleaning high flow pleated filters, it is important to use the right techniques and products to avoid damaging the filter material. One common method of cleaning pleated filters is to use compressed air to blow out any trapped particles. However, it is important to use caution when using compressed air, as excessive pressure can damage the filter material. Instead, use a gentle, sweeping motion to remove any debris from the surface of the filter.

Another effective method of cleaning high flow pleated filters is to soak them in a cleaning solution. There are many commercial cleaning solutions available that are specifically designed for cleaning filters. These solutions can help to break down and remove stubborn contaminants from the filter material, restoring its efficiency. When using a cleaning solution, be sure to follow the manufacturer’s instructions carefully to ensure that the filter is cleaned properly.

In addition to regular cleaning, it is also important to replace high flow pleated filters on a regular basis. Over time, the filter material can become worn out and less effective at removing contaminants. By replacing the filter at regular intervals, you can ensure that your system continues to operate at peak efficiency. Be sure to consult the manufacturer’s recommendations for the proper replacement schedule for your specific filter.

Proper storage of high flow pleated filters is also important in maintaining their effectiveness. Filters should be stored in a clean, dry environment to prevent the growth of mold or bacteria. Additionally, filters should be stored in their original packaging to protect them from damage and contamination. By taking the time to properly store your filters, you can help to extend their lifespan and ensure that they continue to perform at their best.

In conclusion, maintaining and cleaning high flow pleated filters is essential for ensuring their longevity and efficiency. By regularly inspecting, cleaning, and replacing filters, you can extend their lifespan and maximize their performance. Remember to use caution when cleaning filters and always follow the manufacturer’s recommendations for proper maintenance. By following these simple tips, you can keep your high flow pleated filters in top condition and ensure that your system continues to operate at peak efficiency.