How to Select the Best Polyester Filter Mesh Belt for Your Industry

Key Factors to Consider When Choosing Polyester Filter Mesh Belts

When selecting the best polyester filter mesh belt for your industry, it is essential to consider several key factors that can significantly impact the efficiency and effectiveness of your filtration processes. First and foremost, the specific application for which the filter mesh belt will be used plays a crucial role in determining the appropriate specifications. Different industries, such as food processing, pharmaceuticals, and wastewater treatment, have unique requirements that necessitate tailored solutions. Therefore, understanding the operational environment and the type of materials being filtered is vital in making an informed choice.

In addition to the application, the mesh size is another critical factor to consider. The mesh size directly influences the filtration efficiency and the flow rate of the materials being processed. A finer mesh may be required for applications that demand high filtration precision, while a coarser mesh may be more suitable for processes that prioritize higher flow rates. Consequently, it is important to evaluate the balance between filtration efficiency and throughput to ensure optimal performance in your specific application.

Moreover, the material composition of the polyester filter mesh belt should not be overlooked. Polyester is known for its durability and resistance to various chemicals, making it a popular choice in many industries. However, the specific grade of polyester can vary, and selecting a high-quality material that can withstand the operational stresses, such as temperature fluctuations and exposure to corrosive substances, is essential. This consideration not only enhances the longevity of the filter mesh belt but also minimizes the risk of contamination, which is particularly critical in industries like food and pharmaceuticals.

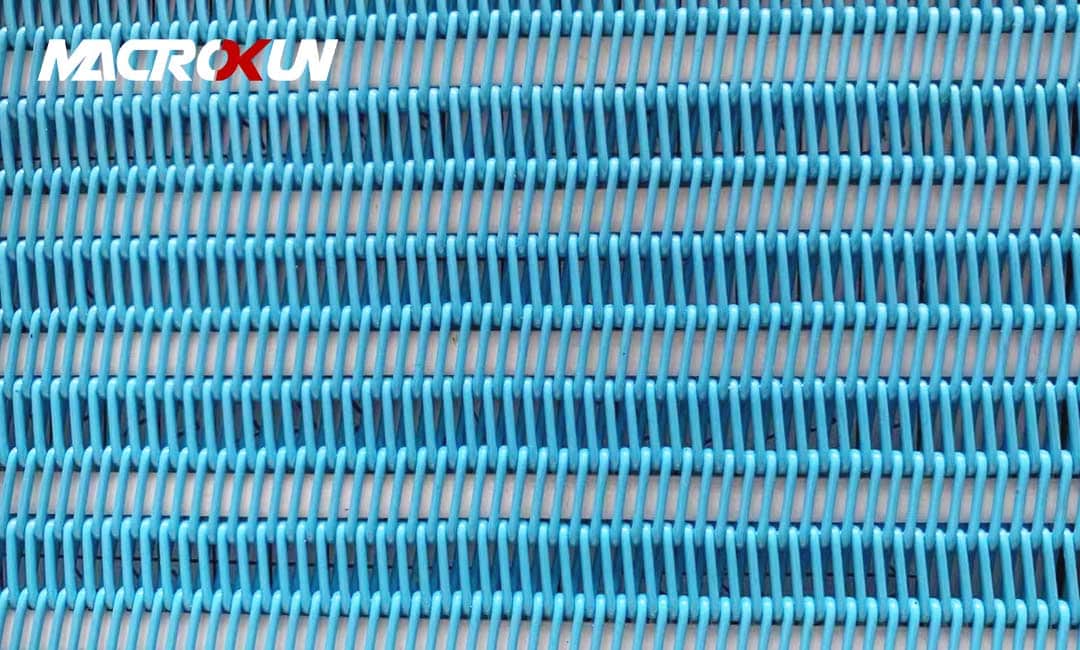

Another important aspect to consider is the belt’s construction and design. The design of the filter mesh belt can affect its performance, including its ability to maintain structural integrity under load and its ease of cleaning. For instance, some belts feature a reinforced design that provides additional strength and stability, which can be beneficial in high-pressure applications. Additionally, ease of maintenance is a significant factor; belts that are easier to clean and maintain can lead to reduced downtime and increased productivity.

Furthermore, compatibility with existing equipment is a vital consideration when selecting a polyester filter mesh belt. It is essential to ensure that the chosen belt can seamlessly integrate with your current filtration systems. This compatibility not only facilitates smoother operations but also helps in avoiding costly modifications or replacements of existing machinery. Therefore, consulting with equipment manufacturers or suppliers can provide valuable insights into the best options available for your specific setup.

Lastly, it is advisable to consider the supplier’s reputation and support services. A reliable supplier can offer not only high-quality products but also technical support and guidance throughout the selection process. Engaging with a supplier who understands your industry’s unique challenges can lead to better recommendations and solutions tailored to your needs. In conclusion, selecting the best polyester filter mesh belt requires careful consideration of various factors, including application requirements, mesh size, material composition, design, compatibility, and supplier support. By thoroughly evaluating these elements, you can ensure that you choose a filter mesh belt that enhances your operational efficiency and meets the specific demands of your industry.

Comparing Different Types of Polyester Filter Mesh Belts for Industrial Applications

When selecting the best polyester filter mesh belt for industrial applications, it is essential to understand the various types available and their specific characteristics. Polyester filter mesh belts are widely used across different industries due to their durability, resistance to chemicals, and ability to withstand high temperatures. However, not all polyester filter mesh belts are created equal, and the choice of the right type can significantly impact operational efficiency and product quality.

To begin with, one must consider the mesh size of the filter belt. The mesh size determines the filtration capability, which is crucial for applications requiring precise separation of solids from liquids. For instance, a finer mesh is ideal for applications in the food and beverage industry, where the removal of small particles is necessary to ensure product purity. Conversely, a coarser mesh may be more suitable for industries such as mining or wastewater treatment, where larger particles need to be filtered out. Therefore, understanding the specific requirements of your application will guide you in selecting the appropriate mesh size.

In addition to mesh size, the thickness of the polyester material plays a vital role in the performance of the filter belt. Thicker belts tend to offer greater strength and durability, making them suitable for heavy-duty applications. However, they may also be less flexible, which could be a disadvantage in processes requiring intricate movements or tight turns. On the other hand, thinner belts provide enhanced flexibility and are often easier to handle, but they may not withstand the same level of wear and tear. Thus, balancing thickness with the operational demands of your industry is crucial for optimal performance.

Moreover, the type of weave used in the construction of the polyester filter mesh belt can influence its filtration efficiency and overall functionality. Common weaving patterns include plain weave, twill weave, and satin weave, each offering distinct advantages. For example, a plain weave provides a uniform surface that is effective for general filtration tasks, while a twill weave offers increased strength and flexibility, making it suitable for more demanding applications. Understanding the specific weaving pattern that aligns with your operational needs will further refine your selection process.

Another important factor to consider is the chemical resistance of the polyester filter mesh belt. Different industrial environments expose materials to various chemicals, and selecting a belt that can withstand these substances is critical to maintaining longevity and performance. For instance, if your application involves exposure to acidic or alkaline solutions, it is essential to choose a polyester filter mesh belt specifically designed to resist such chemicals. This consideration not only ensures the durability of the belt but also minimizes the risk of contamination in your processes.

Finally, it is advisable to evaluate the manufacturer’s reputation and the quality assurance processes they have in place. A reputable manufacturer will provide detailed specifications and performance data for their products, allowing you to make an informed decision. Additionally, seeking feedback from other users in your industry can provide valuable insights into the performance and reliability of specific polyester filter mesh belts.

In conclusion, selecting the best polyester filter mesh belt for your industry requires a comprehensive understanding of various factors, including mesh size, thickness, weave type, chemical resistance, and manufacturer reputation. By carefully considering these elements, you can ensure that you choose a filter belt that meets your operational needs and enhances the efficiency of your industrial processes.

Maintenance Tips for Maximizing the Lifespan of Polyester Filter Mesh Belts

Selecting the best polyester filter mesh belt for your industry is a critical decision that can significantly impact operational efficiency and product quality. However, once the appropriate belt has been chosen, it is equally important to focus on maintenance practices that can maximize its lifespan. Proper maintenance not only ensures optimal performance but also reduces the likelihood of costly downtime and replacements.

To begin with, regular inspection of the polyester filter mesh belt is essential. This involves checking for signs of wear and tear, such as fraying edges, holes, or any form of degradation in the mesh structure. By identifying these issues early, you can address them before they escalate into more significant problems. Additionally, it is advisable to monitor the belt for any misalignment during operation. Misalignment can lead to uneven wear and can compromise the integrity of the belt, ultimately shortening its lifespan.

Furthermore, cleaning the polyester filter mesh belt is a crucial aspect of maintenance. Over time, debris, contaminants, and residues can accumulate on the belt, affecting its filtration efficiency. To maintain optimal performance, it is recommended to clean the belt regularly using appropriate cleaning agents that are compatible with polyester materials. Avoid harsh chemicals that could damage the mesh; instead, opt for mild detergents and warm water. Employing a soft brush or cloth can help remove stubborn residues without causing harm to the belt. After cleaning, ensure that the belt is thoroughly rinsed and dried before reinstallation to prevent any chemical residues from affecting its performance.

In addition to cleaning, lubrication plays a vital role in the maintenance of polyester filter mesh belts. Proper lubrication of the belt’s operating components, such as rollers and pulleys, can reduce friction and wear, thereby extending the belt’s lifespan. It is important to use lubricants that are suitable for the specific operating environment and compatible with polyester materials. Regularly scheduled lubrication checks should be part of your maintenance routine to ensure that all moving parts are functioning smoothly.

Moreover, it is essential to operate the polyester filter mesh belt within the manufacturer’s specified parameters. Overloading the belt or subjecting it to extreme temperatures can lead to premature failure. Therefore, understanding the operational limits of the belt is crucial. This includes adhering to recommended load capacities and temperature ranges, as well as ensuring that the belt is not exposed to harsh environmental conditions that could compromise its structural integrity.

Lastly, training personnel on proper handling and operation of the polyester filter mesh belt can significantly contribute to its longevity. Employees should be educated on the importance of following operational guidelines and maintenance protocols. This not only fosters a culture of care and responsibility but also empowers staff to identify potential issues before they become critical.

In conclusion, maximizing the lifespan of polyester filter mesh belts requires a proactive approach to maintenance. Regular inspections, thorough cleaning, appropriate lubrication, adherence to operational limits, and staff training are all integral components of an effective maintenance strategy. By implementing these practices, industries can ensure that their polyester filter mesh belts operate efficiently and effectively, ultimately leading to enhanced productivity and reduced operational costs.