| Product name: | PTFE hydrophilic filter element |

|---|---|

| Media: | Hydrophilic PTFE membrane |

| Support/Diversion Layer: | PP |

| Shell/Center Rod/End Cap: | PP |

| Sealing material: | Silicone rubber, Ethylene-propylene rubber, Nitrile rubber, Fluorine rubber, Teflon rubber, Teflon-coated fluorine rubber |

| Length: | 10”、20”、30”、40″ |

| Outer diameter: | φ69 mm |

| Maximum operating temperature: | 80°C |

| Maximum working pressure difference: | 4 bar@ 21°C; 2.4 bar@80°C |

- Specifications

-

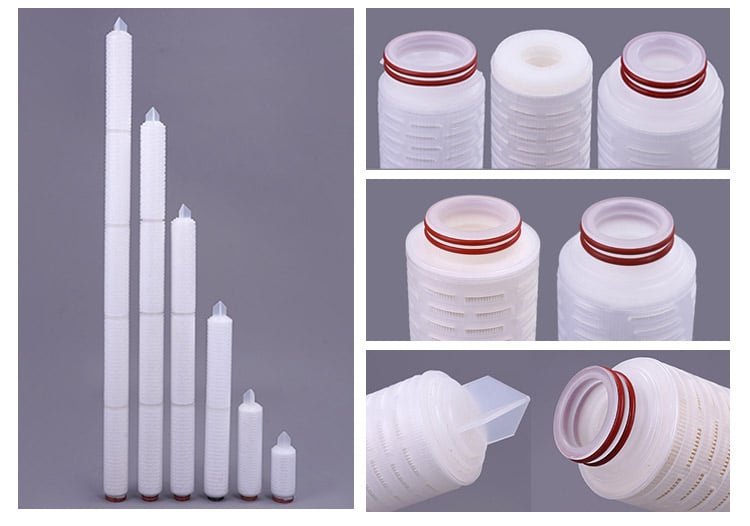

Hydrophilic PTFE Pleated Filter Cartridges Description

Hydrophilic PTFE Membrane Pleated Filter cartridges are composed of high-class absolute rated hydrophilic polytetrafluoroethylene membrane and superior polypropylene components. Besides providing high porosity and permeability, PTFE membrane pleated filters provide high dirt holding capacity to minimize change-outs, high flow rate, long service life and low pressure drop.

The construction of PTFE pleated filter cartridges are all thermal bonded to make sure no adhesives and their wide chemical compatibility allows them to be available in all common configurations and existing filter housings. Each PTFE pleated filter cartridge is pre-flushed with ultra-pure water and was 100% integrity tested before final assembly.

Why Choose Ince’s Hydrophilic PTFE Pleated Filter Cartridge

- INCE’s PTFE Filter Cartridges offer superior filtration efficiency, effectively removing even the smallest particulates.

- Made with polytetrafluoroethylene (PTFE), these cartridges feature excellent chemical and thermal resistance, making them suitable for challenging operating conditions.

- The robust construction ensures longevity, reducing the need for frequent replacements while offering better value for investment.

- Designed with a large filtration area, these cartridges facilitate high flow rates without compromising on quality.

- All of INCE’s products comply with strict industry standards for quality management, ensuring their reliability and performance.

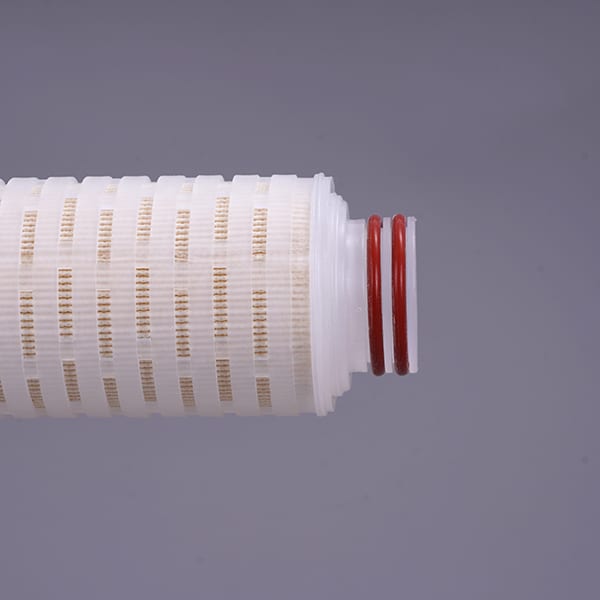

Hydrophilic PTFE Pleated Filter Cartridge Details

- Hot Melt Spinning Process

External transmission and internal density, good pollution interception effect and long service life

- All interfaces use ultrasonic welding.

Customized composite membrane materials

are specially added.The interception efficiency can reach 98%.

- Customized On Demand

Various types of non-standard filter elements can be customized according to different needs of customers.

Hydrophilic PTFE Pleated Filter Cartridge Features:

- 1. PTFE membrane material has excellent chemical compatibility and good tolerance to various liquid materials, and can be used to filter a variety of highly corrosive liquids.

- 2. PTFE membrane material has absolute pore size accuracy, which can provide high filtration efficiency and ensure the removal of impurity particles.

- 3. PTFE membrane material has excellent chemical compatibility and good tolerance to various chemicals. It can be used to filter corrosive liquids such as various etching liquids and stripping liquids.

- 4. The filter element is 100% inspected for integrity.

Hydrophilic PTFE Pleated Filter Cartridge Applications:

- Fermentation tanks, storage tanks, etc. aseptic exhaust, venting filtration

- Electronic industry high purity gas filtration

- High purity steam filtration

- Clarification filtration of corrosive chemicals

- Chemical solvent filtration

Etchants Solvents Photoresists Food & Beverage Final Filtration Storage Tank Vents Prefiltration of RO/DI Semiconductor Electronic industry Chemicals industry Pharmaceutical Industrial Water Treatment Hydrophilic PTFE Pleated Filter Cartridge Performance:

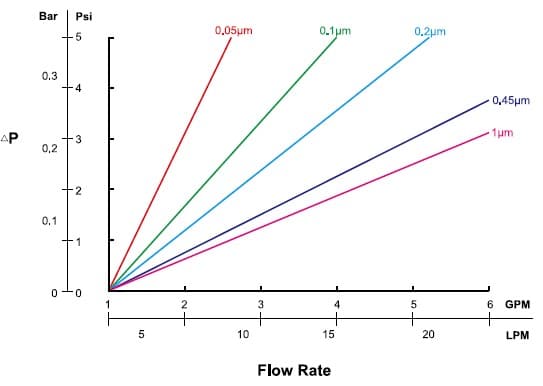

Operation Data for Hydrophilic PTFE Membrane Pleated Filters

Maximum Operating Temperature 90℃(194℉) Max. Differential Pressure 4.8 bar at 20℃(70 psi at 68℉) 2.1 bar at 90℃(30 psi at 194℉) Recommended Change Out Differential Pressure 2.4 bar (35 psid) Sterilization Temperature Time 121˚C (250˚F) for 30 minutes at 1.0 bar (14 psi), multiple cycles Pressure Drop Rate for 10″Hydrophilic PTFE Membrane Pleated Filters

End Caps of Hydrophilic PTFE Pleated Membrane Filter Cartridges:

Search: Select from the options below to search our selection of Hydrophilic PTFE Pleated Filter Cartridge. For questions or custom orders please Contact Us.

Disclaimer:

This information has been provided as a general guide. It is the customer's responsibility to select the proper container for product and application compatibility.Tell us what you need, and we'll help you get quotes