Improving Filtration Efficiency with High Flow Pleated Filters

Benefits of Using High Flow Pleated Filters

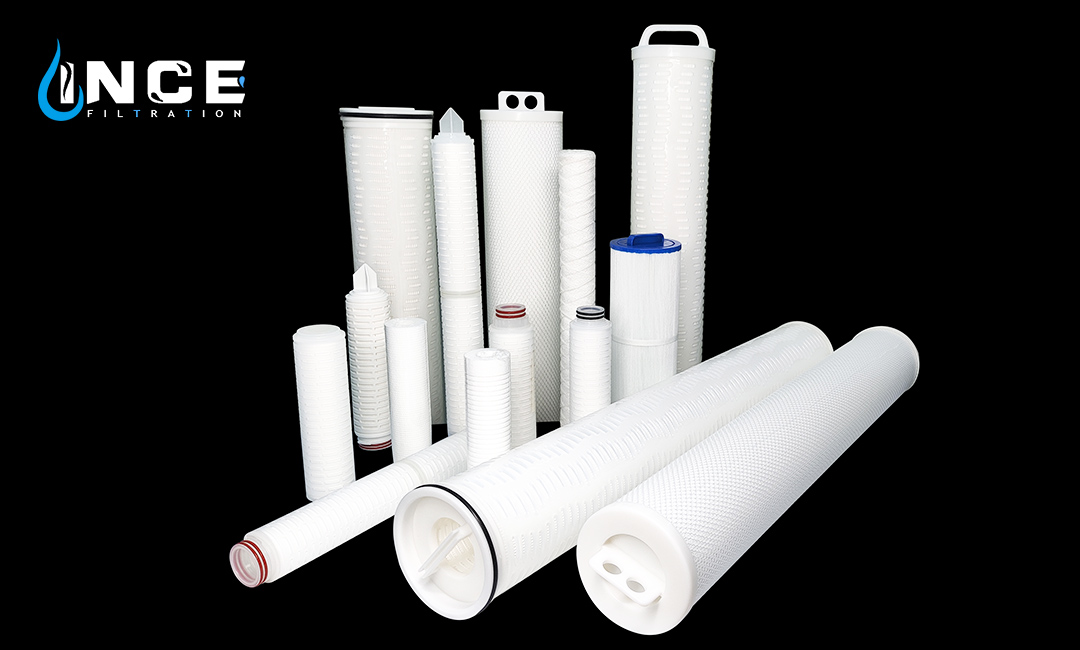

High flow pleated filters are an essential component in many industrial and commercial filtration systems. These filters are designed to improve filtration efficiency by providing a larger surface area for filtration, allowing for higher flow rates and longer filter life. There are several benefits to using high flow pleated filters in your filtration system.

One of the primary benefits of high flow pleated filters is their increased filtration efficiency. The pleated design of these filters provides a larger surface area for filtration, allowing for more particles to be captured and removed from the fluid being filtered. This increased surface area also allows for higher flow rates, meaning that more fluid can be filtered in a shorter amount of time.

In addition to their increased filtration efficiency, high flow pleated filters also have a longer filter life compared to traditional filters. The pleated design of these filters allows for more particles to be captured before the filter needs to be replaced, resulting in less frequent filter changes and lower maintenance costs. This longer filter life can also help to reduce downtime and increase the overall efficiency of your filtration system.

Another benefit of using high flow pleated filters is their versatility. These filters can be used in a wide range of applications, including water treatment, chemical processing, food and beverage production, and more. Their ability to handle high flow rates and provide efficient filtration makes them an ideal choice for many different industries.

High flow pleated filters are also easy to install and maintain, making them a convenient option for filtration systems. These filters can be easily replaced when needed, and their durable construction ensures that they will last for an extended period of time. This ease of maintenance can help to reduce downtime and ensure that your filtration system is operating at peak efficiency.

Overall, high flow pleated filters offer a number of benefits for industrial and commercial filtration systems. Their increased filtration efficiency, longer filter life, versatility, and ease of maintenance make them an ideal choice for many different applications. By incorporating high flow pleated filters into your filtration system, you can improve filtration efficiency, reduce maintenance costs, and increase the overall performance of your system.

Factors Affecting Filtration Efficiency

Filtration efficiency is a critical factor in ensuring the cleanliness and purity of air and water in various industrial and commercial applications. High flow pleated filters are a popular choice for improving filtration efficiency due to their ability to handle high flow rates while maintaining high levels of filtration performance. In this article, we will explore the factors that affect filtration efficiency and how high flow pleated filters can help improve overall filtration performance.

One of the key factors that affect filtration efficiency is the size of the particles being filtered. Smaller particles are more difficult to capture and remove from the air or water, leading to lower filtration efficiency. High flow pleated filters are designed with a large surface area and deep pleats, allowing them to capture a wide range of particle sizes effectively. This design feature helps to improve filtration efficiency by ensuring that even the smallest particles are trapped and removed from the filtration system.

Another important factor that affects filtration efficiency is the flow rate of the air or water being filtered. High flow pleated filters are specifically designed to handle high flow rates without compromising filtration performance. The deep pleats and large surface area of these filters allow for increased airflow while still maintaining high levels of filtration efficiency. This makes high flow pleated filters an ideal choice for applications that require high flow rates and efficient filtration.

The material used in the construction of the filter also plays a significant role in determining filtration efficiency. High flow pleated filters are typically made from high-quality materials such as synthetic fibers or glass fibers, which are known for their superior filtration properties. These materials are designed to capture and retain particles effectively, ensuring that the air or water passing through the filter is clean and free of contaminants. By using high-quality materials, high flow pleated filters can improve filtration efficiency and provide better overall filtration performance.

In addition to particle size, flow rate, and filter material, the design of the filter itself can also impact filtration efficiency. High flow pleated filters are engineered with a specific design that maximizes filtration performance. The deep pleats and large surface area of these filters create a tortuous path for air or water to flow through, increasing the chances of particles being captured and removed from the filtration system. This design feature helps to improve filtration efficiency by ensuring that the filter can effectively trap contaminants and provide clean, purified air or water.

Overall, high flow pleated filters are an excellent choice for improving filtration efficiency in a wide range of applications. Their ability to handle high flow rates, capture small particles, and use high-quality materials make them a reliable and effective option for enhancing filtration performance. By understanding the factors that affect filtration efficiency and choosing high flow pleated filters that are specifically designed to address these factors, businesses and industries can ensure that their filtration systems operate at peak performance and provide clean, purified air and water for their operations.

Comparison of High Flow Pleated Filters with Traditional Filters

High flow pleated filters are becoming increasingly popular in industrial and commercial applications due to their superior filtration efficiency compared to traditional filters. In this article, we will compare high flow pleated filters with traditional filters to highlight the benefits of using high flow pleated filters in various industries.

Traditional filters are typically made of paper, cloth, or other porous materials that trap particles as fluid passes through them. While these filters are effective to some extent, they have limitations in terms of filtration efficiency and flow rate. High flow pleated filters, on the other hand, are designed with a larger surface area and higher dirt-holding capacity, allowing for better filtration performance and longer service life.

One of the key advantages of high flow pleated filters is their ability to handle higher flow rates without sacrificing filtration efficiency. Traditional filters may become clogged or damaged when subjected to high flow rates, leading to decreased performance and increased maintenance costs. High flow pleated filters, with their larger surface area and optimized pleat design, can maintain high filtration efficiency even at high flow rates, making them ideal for applications that require continuous and efficient filtration.

Another important factor to consider when comparing high flow pleated filters with traditional filters is the pressure drop across the filter. Traditional filters often have a higher pressure drop due to their limited surface area and smaller pore size, which can result in increased energy consumption and reduced system efficiency. High flow pleated filters, with their larger surface area and lower pressure drop, can provide the same level of filtration efficiency with less energy consumption, leading to cost savings and improved system performance.

In addition to their superior filtration efficiency and lower pressure drop, high flow pleated filters are also more durable and resistant to damage compared to traditional filters. The pleated design of high flow filters provides structural integrity and support, preventing collapse or deformation under high flow rates or pressure. This durability ensures longer service life and reduced maintenance costs, making high flow pleated filters a cost-effective solution for various filtration applications.

Furthermore, high flow pleated filters are available in a wide range of materials and configurations to meet specific filtration requirements. Whether it is for removing particles, contaminants, or odors, high flow pleated filters can be customized to suit different applications and industries. From water treatment and chemical processing to food and beverage production, high flow pleated filters offer versatile and reliable filtration solutions for a variety of applications.

In conclusion, high flow pleated filters offer numerous advantages over traditional filters in terms of filtration efficiency, flow rate, pressure drop, durability, and customization options. By choosing high flow pleated filters for your filtration needs, you can improve system performance, reduce maintenance costs, and ensure consistent and reliable filtration in various industrial and commercial applications.Upgrade to high flow pleated filters today and experience the benefits of superior filtration efficiency.

Tips for Maintaining and Maximizing Efficiency of High Flow Pleated Filters

High flow pleated filters are an essential component in many industrial and commercial filtration systems. These filters are designed to handle high flow rates while maintaining excellent filtration efficiency. However, like any filtration system, high flow pleated filters require proper maintenance to ensure optimal performance. In this article, we will discuss some tips for maintaining and maximizing the efficiency of high flow pleated filters.

One of the most important factors in maintaining the efficiency of high flow pleated filters is regular cleaning. Over time, dirt, debris, and other contaminants can build up on the surface of the filter, reducing its effectiveness. To prevent this buildup, it is essential to clean the filter regularly according to the manufacturer’s recommendations. This may involve rinsing the filter with water or using a specialized cleaning solution.

In addition to regular cleaning, it is also important to inspect the filter for any signs of damage or wear. Cracks, tears, or other defects in the filter material can compromise its ability to effectively capture contaminants. If any damage is found, the filter should be replaced immediately to prevent any further issues.

Another important tip for maintaining high flow pleated filters is to ensure proper installation. Filters that are not installed correctly may not seal properly, allowing contaminants to bypass the filter and enter the system. It is essential to follow the manufacturer’s instructions carefully when installing a new filter to ensure a proper fit and seal.

In addition to proper installation, it is also important to monitor the pressure drop across the filter. A sudden increase in pressure drop may indicate that the filter is becoming clogged and needs to be cleaned or replaced. Monitoring the pressure drop regularly can help prevent issues before they become more severe.

To maximize the efficiency of high flow pleated filters, it is also important to choose the right filter for the application. Different filters are designed to capture different types and sizes of contaminants, so it is essential to select a filter that is appropriate for the specific needs of the system. Consulting with a filtration expert can help ensure that the right filter is chosen for the job.

Finally, it is important to consider the overall system design when maximizing the efficiency of high flow pleated filters. Properly sizing the filter and ensuring that it is integrated into the system correctly can help optimize performance. Regularly monitoring and maintaining the entire filtration system can help prevent issues and ensure that the filter continues to operate at peak efficiency.

In conclusion, high flow pleated filters are an essential component in many filtration systems, and proper maintenance is crucial to ensuring optimal performance. By following these tips for maintaining and maximizing the efficiency of high flow pleated filters, system operators can help extend the life of the filter and improve overall filtration performance. Regular cleaning, inspection, proper installation, monitoring pressure drop, choosing the right filter, and considering system design are all important factors to consider when working with high flow pleated filters. By taking these steps, system operators can help ensure that their filtration systems continue to operate efficiently and effectively.