Industries That Thrive with High Flow Pleated Filter Cartridges

Benefits of Using High Flow Pleated Filter Cartridges in the Food and Beverage Industry

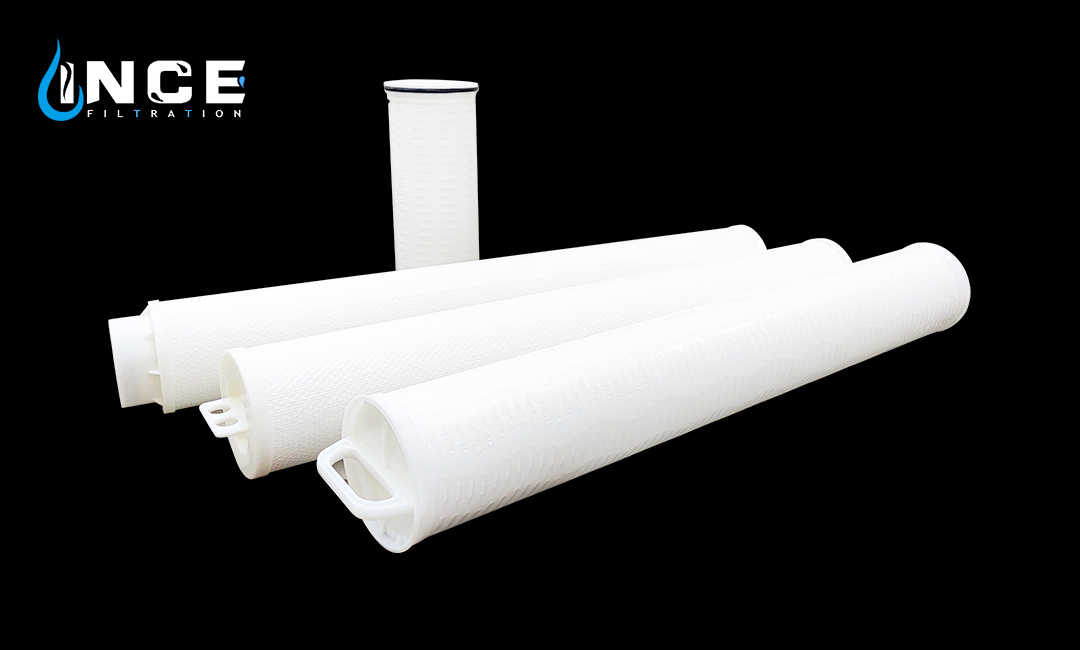

High flow pleated filter cartridges are an essential component in various industries, including the food and beverage industry. These filter cartridges are designed to handle high flow rates while effectively removing contaminants from liquids. In the food and beverage industry, maintaining high levels of cleanliness and quality is crucial to ensure the safety of consumers. High flow pleated filter cartridges play a vital role in achieving this goal by providing efficient filtration of liquids used in the production process.

One of the key benefits of using high flow pleated filter cartridges in the food and beverage industry is their ability to remove a wide range of contaminants. These filter cartridges are designed with a large surface area and pleated design, allowing them to capture particles of various sizes. This ensures that the liquids used in the production process are free from impurities, such as dirt, debris, and microorganisms. By using high flow pleated filter cartridges, food and beverage manufacturers can maintain high levels of cleanliness and quality in their products.

Another advantage of using high flow pleated filter cartridges in the food and beverage industry is their efficiency in handling high flow rates. These filter cartridges are designed to accommodate high flow rates, allowing for faster filtration of liquids. This is particularly important in the food and beverage industry, where large volumes of liquids are processed on a daily basis. High flow pleated filter cartridges help to streamline the filtration process, ensuring that production runs smoothly and efficiently.

In addition to their efficiency in handling high flow rates, high flow pleated filter cartridges are also cost-effective. These filter cartridges have a longer lifespan compared to traditional filter cartridges, reducing the need for frequent replacements. This not only saves money on maintenance costs but also minimizes downtime in production. By using high flow pleated filter cartridges, food and beverage manufacturers can improve their operational efficiency and reduce overall costs.

Furthermore, high flow pleated filter cartridges are easy to install and maintain, making them a convenient choice for the food and beverage industry. These filter cartridges can be easily replaced when needed, without requiring specialized tools or equipment. This allows for quick and hassle-free maintenance, ensuring that production can continue without interruption. The ease of installation and maintenance of high flow pleated filter cartridges makes them a practical choice for food and beverage manufacturers looking to streamline their filtration processes.

Overall, high flow pleated filter cartridges are a valuable asset to the food and beverage industry. Their ability to remove contaminants, handle high flow rates, and provide cost-effective filtration make them an essential component in ensuring the cleanliness and quality of products. By incorporating high flow pleated filter cartridges into their production processes, food and beverage manufacturers can improve efficiency, reduce costs, and maintain high standards of quality and safety.

How High Flow Pleated Filter Cartridges Improve Efficiency in the Pharmaceutical Industry

High flow pleated filter cartridges are essential components in various industries, including the pharmaceutical sector. These filter cartridges play a crucial role in improving efficiency, ensuring product quality, and maintaining regulatory compliance. In this article, we will explore how high flow pleated filter cartridges benefit the pharmaceutical industry and contribute to its success.

One of the primary advantages of high flow pleated filter cartridges in the pharmaceutical industry is their ability to remove contaminants and impurities from process fluids effectively. These filter cartridges are designed to trap particles of various sizes, ranging from large debris to microscopic contaminants. By removing these impurities, high flow pleated filter cartridges help ensure that pharmaceutical products meet the highest quality standards and are safe for consumption.

In addition to improving product quality, high flow pleated filter cartridges also play a crucial role in maintaining the efficiency of pharmaceutical manufacturing processes. By removing contaminants from process fluids, these filter cartridges help prevent clogging and fouling of equipment, such as pumps, valves, and heat exchangers. This, in turn, reduces downtime for maintenance and cleaning, allowing pharmaceutical companies to operate more efficiently and cost-effectively.

Furthermore, high flow pleated filter cartridges are designed to handle high flow rates, making them ideal for use in large-scale pharmaceutical manufacturing operations. These filter cartridges can process a significant volume of process fluids quickly and efficiently, ensuring that production targets are met and deadlines are adhered to. This high flow capacity also helps pharmaceutical companies increase their overall productivity and output, leading to greater profitability and success.

Another key benefit of high flow pleated filter cartridges in the pharmaceutical industry is their compatibility with a wide range of process fluids and chemicals. These filter cartridges are available in various materials, such as polypropylene, polyester, and PTFE, which are resistant to corrosion and chemical degradation. This versatility allows pharmaceutical companies to use high flow pleated filter cartridges in a variety of applications, from water purification to solvent filtration, without compromising performance or product quality.

Moreover, high flow pleated filter cartridges are easy to install, replace, and maintain, making them a cost-effective solution for pharmaceutical companies. These filter cartridges can be quickly swapped out when needed, minimizing downtime and ensuring continuous operation. Additionally, high flow pleated filter cartridges have a long service life, reducing the frequency of replacements and lowering overall operating costs for pharmaceutical manufacturers.

In conclusion, high flow pleated filter cartridges are essential components that help improve efficiency, ensure product quality, and maintain regulatory compliance in the pharmaceutical industry. These filter cartridges remove contaminants from process fluids, prevent equipment clogging, handle high flow rates, and are compatible with a wide range of chemicals. Their ease of installation, replacement, and maintenance make them a cost-effective solution for pharmaceutical companies looking to enhance their manufacturing processes. Overall, high flow pleated filter cartridges play a vital role in the success and growth of the pharmaceutical industry.

Case Studies of Industries Achieving Cost Savings with High Flow Pleated Filter Cartridges

High flow pleated filter cartridges have become a popular choice for industries looking to achieve cost savings while maintaining high filtration efficiency. These filter cartridges are designed to handle high flow rates, making them ideal for industries that require large volumes of liquid to be filtered quickly and efficiently. In this article, we will explore some case studies of industries that have successfully implemented high flow pleated filter cartridges and have seen significant cost savings as a result.

One industry that has benefited greatly from the use of high flow pleated filter cartridges is the food and beverage industry. With strict regulations in place to ensure the safety and quality of food and beverages, it is essential for companies in this industry to have reliable filtration systems in place. High flow pleated filter cartridges provide the perfect solution, as they are able to handle the high flow rates required for processing large volumes of liquid while effectively removing contaminants and impurities.

By using high flow pleated filter cartridges, companies in the food and beverage industry have been able to reduce their operating costs significantly. These filter cartridges have a longer lifespan than traditional filter cartridges, which means that companies can save money on replacement costs. Additionally, the high filtration efficiency of these cartridges means that companies can reduce the amount of product wastage, further contributing to cost savings.

Another industry that has seen great success with high flow pleated filter cartridges is the pharmaceutical industry. With stringent regulations in place to ensure the safety and efficacy of pharmaceutical products, it is crucial for companies in this industry to have reliable filtration systems in place. High flow pleated filter cartridges provide the perfect solution, as they are able to handle the high flow rates required for processing pharmaceutical products while maintaining the high level of filtration efficiency required.

By using high flow pleated filter cartridges, companies in the pharmaceutical industry have been able to achieve significant cost savings. These filter cartridges are able to remove even the smallest particles and contaminants from pharmaceutical products, ensuring that they meet the strict quality standards set by regulatory bodies. This has helped companies in the pharmaceutical industry to reduce product wastage and improve overall product quality, leading to cost savings in the long run.

The automotive industry is another sector that has benefited from the use of high flow pleated filter cartridges. With the need to filter large volumes of oil, coolant, and other fluids in automotive manufacturing processes, it is essential for companies in this industry to have efficient filtration systems in place. High flow pleated filter cartridges provide the perfect solution, as they are able to handle the high flow rates required for processing automotive fluids while effectively removing contaminants and impurities.

By using high flow pleated filter cartridges, companies in the automotive industry have been able to achieve significant cost savings. These filter cartridges are able to maintain their filtration efficiency even at high flow rates, reducing the need for frequent replacements. This has helped companies in the automotive industry to reduce downtime and maintenance costs, leading to overall cost savings.

In conclusion, high flow pleated filter cartridges have proven to be a valuable asset for industries looking to achieve cost savings while maintaining high filtration efficiency. By implementing these filter cartridges, companies in a variety of industries have been able to reduce operating costs, improve product quality, and increase overall efficiency. As technology continues to advance, high flow pleated filter cartridges will likely become an even more essential component of filtration systems in industries around the world.

The Environmental Impact of High Flow Pleated Filter Cartridges in Manufacturing Industries

High flow pleated filter cartridges are an essential component in many manufacturing industries, providing a cost-effective and efficient solution for filtering liquids and gases. These filter cartridges are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for industries that require large volumes of filtered fluids. One of the key benefits of high flow pleated filter cartridges is their ability to reduce maintenance costs and downtime, as they have a longer lifespan compared to traditional filter cartridges.

One industry that greatly benefits from the use of high flow pleated filter cartridges is the food and beverage industry. In this industry, maintaining high levels of cleanliness and hygiene is crucial to ensure the safety of the products being produced. High flow pleated filter cartridges help to remove contaminants and impurities from liquids such as water, juices, and syrups, ensuring that the final products meet the required quality standards. By using high flow pleated filter cartridges, food and beverage manufacturers can improve the overall quality of their products while reducing the risk of contamination.

Another industry that relies heavily on high flow pleated filter cartridges is the pharmaceutical industry. In this highly regulated industry, maintaining a clean and sterile environment is essential to ensure the safety and efficacy of pharmaceutical products. High flow pleated filter cartridges play a critical role in removing bacteria, viruses, and other harmful contaminants from liquids and gases used in the production process. By using high flow pleated filter cartridges, pharmaceutical manufacturers can meet the stringent regulatory requirements and produce high-quality products that are safe for consumption.

The automotive industry is another sector that benefits from the use of high flow pleated filter cartridges. In this industry, the quality of the fluids used in manufacturing processes directly impacts the performance and longevity of vehicles. High flow pleated filter cartridges help to remove contaminants and particles from fluids such as lubricants, coolants, and hydraulic fluids, ensuring that the components of vehicles operate smoothly and efficiently. By using high flow pleated filter cartridges, automotive manufacturers can improve the overall quality of their products and reduce the risk of equipment failure.

The chemical industry also relies on high flow pleated filter cartridges to ensure the purity of chemicals used in various processes. Contaminants and impurities in chemicals can have a significant impact on the quality of the final products, leading to costly production errors and waste. High flow pleated filter cartridges help to remove particles and contaminants from chemicals, ensuring that they meet the required purity standards. By using high flow pleated filter cartridges, chemical manufacturers can improve the quality of their products and reduce the risk of contamination.

In conclusion, high flow pleated filter cartridges play a crucial role in various manufacturing industries, helping to improve the quality of products while reducing maintenance costs and downtime. Industries such as food and beverage, pharmaceutical, automotive, and chemical rely on high flow pleated filter cartridges to ensure the cleanliness and purity of liquids and gases used in production processes. By investing in high flow pleated filter cartridges, manufacturers can enhance the efficiency and effectiveness of their operations, ultimately leading to improved product quality and customer satisfaction.