Is Double Bagging Worth It for Rosin Pressing? Pros and Cons

Benefits of Double Bagging in Rosin Pressing

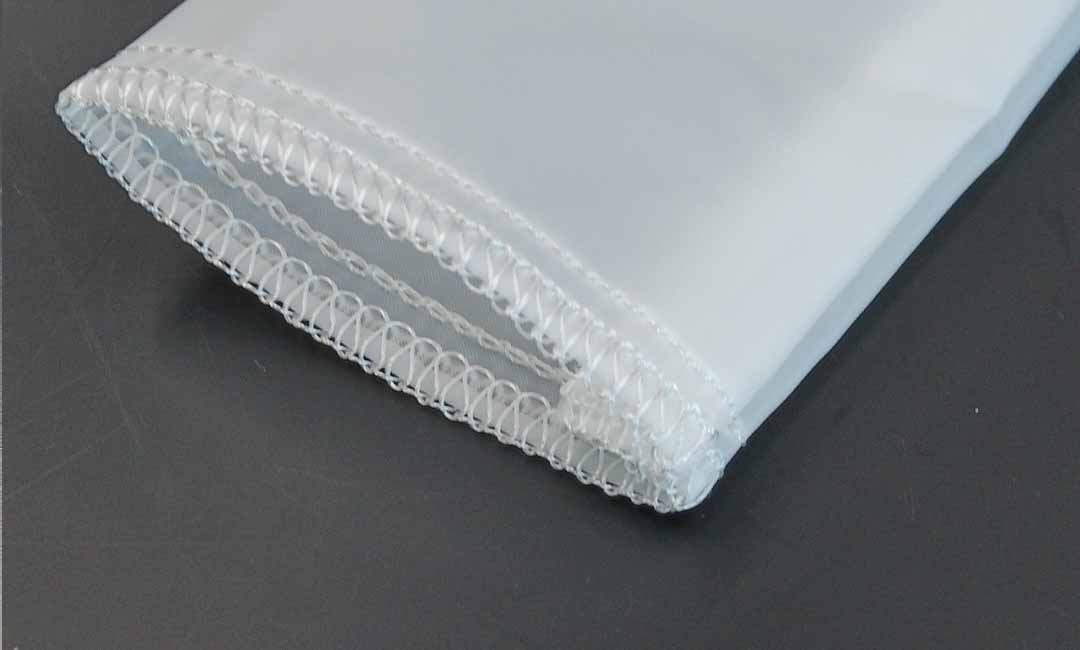

Double bagging in rosin pressing has emerged as a popular technique among enthusiasts and professionals alike, primarily due to its potential benefits in enhancing the quality and yield of the final product. This method involves using two bags, typically made of micron mesh, to contain the plant material during the pressing process. One of the primary advantages of double bagging is the increased filtration it provides. By utilizing two bags, the likelihood of unwanted plant material, such as fine particles and contaminants, making their way into the final rosin is significantly reduced. This results in a cleaner product that not only looks more appealing but also offers a more refined flavor profile, which is particularly important for connoisseurs who prioritize quality.

Moreover, double bagging can lead to improved yields. When the plant material is contained within two bags, it allows for better distribution of pressure during the pressing process. This even distribution can help extract more resin from the plant material, ultimately increasing the amount of rosin produced. As a result, users may find that the additional effort of double bagging pays off in terms of both quantity and quality, making it a worthwhile consideration for those looking to maximize their output.

In addition to enhancing yield and purity, double bagging can also provide a level of protection for the bags themselves. During the pressing process, the bags are subjected to significant pressure and heat, which can sometimes lead to tears or ruptures. By using two bags, the inner bag is shielded from direct contact with the heated plates, reducing the risk of damage. This added layer of protection can be particularly beneficial when working with more delicate strains or when pressing larger quantities of material, as it helps ensure that the integrity of the bags is maintained throughout the process.

Another noteworthy benefit of double bagging is the versatility it offers. Different micron sizes can be used for each bag, allowing users to customize their filtration process based on the specific characteristics of the material being pressed. For instance, a larger micron bag can be used as the outer layer to catch larger particles, while a smaller micron bag can be employed as the inner layer to filter out finer particles. This flexibility enables users to tailor their approach to achieve the desired consistency and quality of rosin, catering to individual preferences and requirements.

However, it is essential to consider the potential downsides of double bagging as well. The process can be more time-consuming and may require additional materials, which could deter some users. Additionally, if not executed properly, double bagging could lead to complications such as uneven pressure distribution or difficulty in extracting the rosin from the bags. Therefore, while the benefits of double bagging in rosin pressing are substantial, it is crucial for users to weigh these advantages against the potential challenges.

In conclusion, double bagging presents several compelling benefits for those engaged in rosin pressing. From improved filtration and increased yields to enhanced protection and customization options, this technique can significantly elevate the quality of the final product. However, it is essential for users to approach the method with an understanding of its complexities and to consider their specific needs and circumstances. Ultimately, the decision to double bag should be informed by a careful assessment of both the pros and cons, ensuring that the chosen method aligns with the desired outcomes in rosin production.

Drawbacks of Double Bagging for Rosin Extraction

Double bagging is a technique often employed in the rosin pressing process, where cannabis material is enclosed in two bags before being subjected to heat and pressure. While this method is intended to enhance the quality and yield of the extracted rosin, it is essential to consider the drawbacks associated with double bagging. Understanding these limitations can help users make informed decisions about their extraction methods.

One of the primary drawbacks of double bagging is the potential for reduced yield. When cannabis material is placed in two bags, the additional layer can create extra resistance during the pressing process. This resistance may hinder the flow of the rosin, leading to a lower quantity of extract being produced. Consequently, users may find that the effort and resources invested in double bagging do not translate into a proportional increase in yield, which can be particularly frustrating for those seeking to maximize their extraction efficiency.

Moreover, double bagging can complicate the extraction process. The use of two bags requires careful handling and additional steps, which can introduce variables that may affect the final product. For instance, if the bags are not aligned correctly or if there is an issue with the sealing, the extraction may be compromised. This complexity can lead to inconsistencies in the quality of the rosin, as variations in the pressing technique or bag integrity can result in different outcomes. As a result, users may find themselves spending more time troubleshooting issues rather than focusing on refining their extraction methods.

Another significant concern with double bagging is the potential for contamination. While the intention behind using two bags is to create a barrier that protects the cannabis material, there is still a risk that contaminants can enter the extraction process. For example, if the outer bag is not clean or if it comes into contact with unclean surfaces, there is a possibility that unwanted substances could be introduced into the rosin. This contamination can compromise the purity and safety of the final product, which is particularly concerning for consumers who prioritize high-quality, clean extracts.

Additionally, double bagging can lead to increased costs. The need for additional materials, such as extra bags and possibly more robust pressing equipment, can add to the overall expense of the extraction process. For small-scale producers or home users, these costs may not be justifiable, especially if the benefits of double bagging do not significantly outweigh the drawbacks. In a market where profit margins can be tight, it is crucial for users to evaluate whether the potential advantages of double bagging are worth the financial investment.

Lastly, the environmental impact of double bagging should not be overlooked. The use of additional plastic bags contributes to waste, which is a growing concern in the cannabis industry and beyond. As consumers become more environmentally conscious, the practice of double bagging may be viewed unfavorably, prompting users to seek more sustainable extraction methods. This shift in consumer preferences could influence the long-term viability of double bagging as a standard practice in rosin extraction.

In conclusion, while double bagging may offer some benefits in terms of protecting the cannabis material during the rosin pressing process, the drawbacks are significant. Reduced yield, increased complexity, potential contamination, higher costs, and environmental concerns all warrant careful consideration. As the industry continues to evolve, users must weigh these factors against their specific needs and goals to determine whether double bagging is a worthwhile practice for their rosin extraction endeavors.

Comparing Yields: Double Bagging vs. Single Bagging

When it comes to rosin pressing, one of the most debated topics among enthusiasts and professionals alike is the practice of double bagging versus single bagging. This discussion is particularly relevant for those seeking to maximize their yields while maintaining the quality of their extracts. To understand the implications of each method, it is essential to consider the differences in yield, quality, and overall efficiency.

Single bagging involves using a single micron bag to contain the material during the pressing process. This method is straightforward and often preferred for its simplicity. However, the yield can be somewhat limited, as the single bag may not effectively capture all the resinous material. In contrast, double bagging entails using two bags, typically of different micron sizes, to create a more refined filtration system. The outer bag serves as a protective layer, while the inner bag, which holds the material, allows for better extraction of the desired oils. This dual-layer approach can lead to a more efficient extraction process, as it minimizes the risk of contamination from plant material.

When comparing yields, many users report that double bagging can significantly enhance the amount of rosin extracted. The additional filtration provided by the second bag can help to trap more of the resin, which might otherwise be lost in a single bagging scenario. This is particularly beneficial when working with lower-quality starting material, where the potential for contaminants is higher. By using double bags, the risk of unwanted plant matter making its way into the final product is reduced, thereby improving the overall yield and quality of the rosin.

Moreover, the micron size of the bags plays a crucial role in determining the effectiveness of the extraction process. For instance, using a smaller micron size for the inner bag can help to capture finer particles, which may contain more of the desirable terpenes and cannabinoids. Conversely, a larger micron size for the outer bag allows for better drainage and prevents clogging, ensuring a smoother pressing experience. This careful selection of bag sizes can further enhance the yield when double bagging is employed.

However, it is important to consider the potential downsides of double bagging. The process can be more time-consuming and may require additional preparation, as users must ensure that both bags are properly aligned and secured. Additionally, the cost of purchasing multiple bags can add up, particularly for those who press rosin frequently. Some users may find that the increased yield does not justify the extra effort and expense involved in double bagging, especially if they are working with high-quality material that yields well even with single bagging.

In conclusion, the decision to double bag or single bag when pressing rosin ultimately depends on individual preferences and specific circumstances. While double bagging can lead to higher yields and improved quality, it also requires more time and resources. For those who prioritize efficiency and are willing to invest in the process, double bagging may prove to be a worthwhile endeavor. Conversely, individuals who are satisfied with their current yields and prefer a more straightforward approach may find single bagging to be sufficient. Ultimately, understanding the nuances of each method allows users to make informed choices that align with their goals in rosin pressing.

Best Practices for Double Bagging in Rosin Pressing

Double bagging in rosin pressing has emerged as a popular technique among enthusiasts and professionals alike, primarily due to its potential benefits in enhancing the quality and yield of the final product. However, to fully appreciate the merits and drawbacks of this method, it is essential to understand the best practices associated with double bagging. This approach involves using two bags instead of one during the pressing process, which can help mitigate issues such as contamination and material loss.

To begin with, selecting the right type of bags is crucial for successful double bagging. Typically, rosin bags are made from nylon or other heat-resistant materials that can withstand the high temperatures involved in the pressing process. When opting for double bagging, it is advisable to use bags with a micron rating that suits the specific material being pressed. For instance, bags with a micron rating of 25 to 160 are commonly used, as they allow for optimal oil extraction while filtering out unwanted plant material. By carefully choosing the appropriate micron size, users can ensure that the quality of the rosin is not compromised.

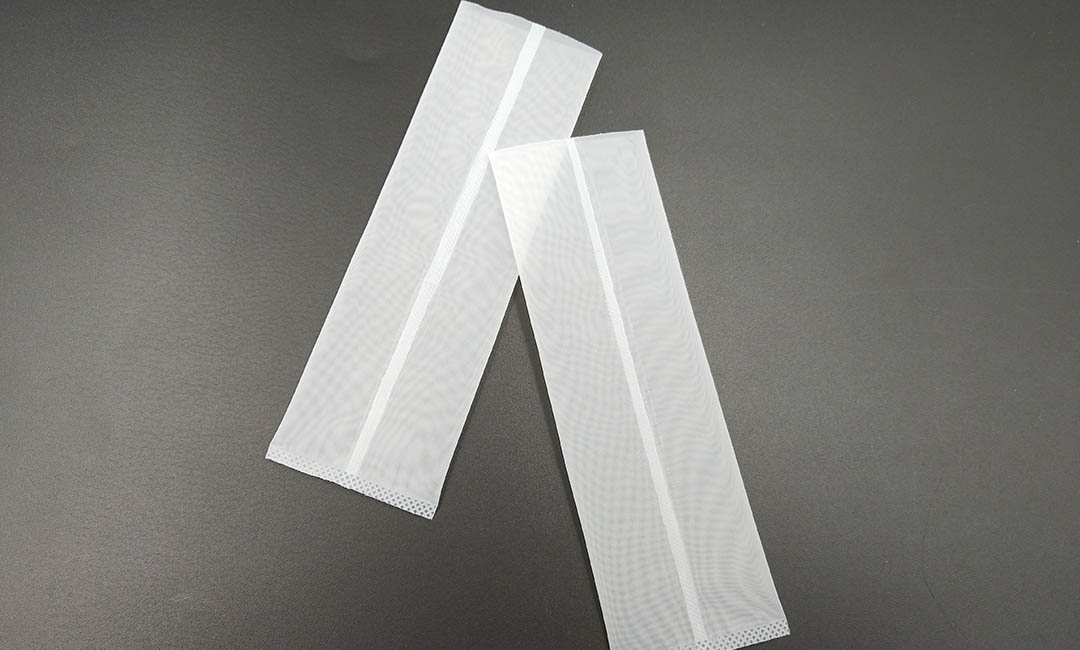

Once the right bags are selected, the next step involves preparing the material for pressing. It is essential to ensure that the starting material is adequately dried and cured, as moisture can negatively impact the quality of the rosin. Additionally, breaking down the material into smaller pieces can facilitate a more even extraction during the pressing process. When using double bags, it is advisable to place the material in the inner bag first, ensuring that it is evenly distributed. After securing the inner bag, it should then be placed inside the outer bag, which serves as an additional layer of protection against contamination and helps to contain any potential mess during pressing.

During the pressing process, maintaining the right temperature and pressure is vital for achieving optimal results. It is generally recommended to start with lower temperatures and gradually increase them, as this can help preserve the terpenes and cannabinoids present in the material. When using double bags, it is important to monitor the pressure closely, as excessive pressure can lead to the inner bag bursting, which would defeat the purpose of double bagging. Therefore, applying consistent and controlled pressure is essential to ensure that the inner bag remains intact while allowing for effective oil extraction.

After the pressing is complete, careful handling of the bags is necessary to maximize yield. Gently removing the outer bag first can help prevent any potential spillage of the rosin contained within the inner bag. It is also advisable to allow the inner bag to cool slightly before opening it, as this can make it easier to extract the rosin without losing any product. Additionally, using a clean tool to scrape the rosin from the bag can help ensure that the final product is free from contaminants.

In conclusion, while double bagging can offer several advantages in rosin pressing, such as improved cleanliness and potentially higher yields, it is essential to adhere to best practices to fully realize these benefits. By selecting the right bags, preparing the material properly, maintaining appropriate temperature and pressure, and handling the bags with care, users can enhance their rosin pressing experience. Ultimately, the decision to double bag should be based on individual preferences and the specific goals of the pressing process, as the effectiveness of this technique can vary depending on various factors.