Key Benefits of Industrial Spiral Dryer Fabric in Manufacturing

Enhanced Drying Efficiency

In the realm of manufacturing, the efficiency of drying processes plays a pivotal role in determining overall productivity and product quality. One of the most significant advancements in this area is the use of industrial spiral dryer fabric, which has revolutionized the way materials are dried in various industries. The enhanced drying efficiency provided by this innovative fabric is a key benefit that manufacturers are increasingly recognizing.

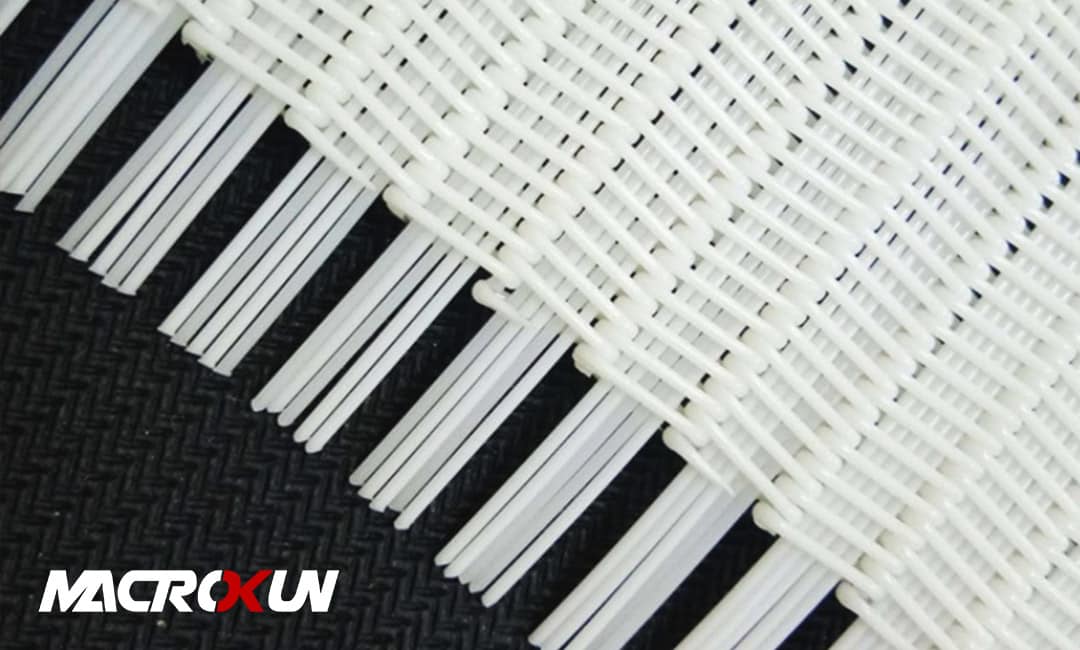

To begin with, the design of spiral dryer fabric is specifically engineered to optimize airflow and heat transfer, which are critical factors in the drying process. Unlike traditional drying methods, which often rely on static surfaces, spiral dryer fabric allows for continuous movement of materials through the drying zone. This dynamic movement not only facilitates uniform drying but also minimizes the risk of material clumping or uneven moisture distribution. As a result, manufacturers can achieve a more consistent product quality, which is essential for maintaining standards and meeting customer expectations.

Moreover, the enhanced drying efficiency of spiral dryer fabric translates directly into time savings. In manufacturing environments where time is a crucial factor, the ability to reduce drying times can lead to significant increases in throughput. By utilizing spiral dryer fabric, manufacturers can process larger volumes of materials in a shorter period, thereby maximizing production capacity. This efficiency is particularly beneficial in industries such as paper, textiles, and food processing, where drying is a critical step in the production cycle.

In addition to time savings, the use of spiral dryer fabric can also lead to energy savings. Traditional drying methods often consume substantial amounts of energy, which can contribute to higher operational costs. However, the optimized airflow and heat transfer characteristics of spiral dryer fabric allow for more efficient use of energy resources. By reducing the energy required for drying, manufacturers can not only lower their operational expenses but also contribute to more sustainable production practices. This aspect is increasingly important in today’s manufacturing landscape, where environmental considerations are becoming paramount.

Furthermore, the durability and longevity of spiral dryer fabric enhance its cost-effectiveness over time. Made from high-quality materials that withstand the rigors of industrial use, this fabric is designed to resist wear and tear, ensuring a longer service life compared to conventional drying fabrics. Consequently, manufacturers can reduce the frequency of fabric replacements, leading to lower maintenance costs and less downtime in production. This reliability is a crucial factor for manufacturers aiming to maintain continuous operations and minimize disruptions.

Another noteworthy advantage of industrial spiral dryer fabric is its versatility. It can be adapted to various drying applications across different industries, making it a valuable asset for manufacturers with diverse product lines. Whether drying paper sheets, textile fabrics, or food products, the adaptability of spiral dryer fabric ensures that manufacturers can achieve optimal drying results tailored to their specific needs.

In conclusion, the enhanced drying efficiency provided by industrial spiral dryer fabric is a transformative benefit for manufacturers. By improving airflow and heat transfer, reducing drying times, and lowering energy consumption, this innovative fabric not only boosts productivity but also supports sustainable practices. Additionally, its durability and versatility make it a wise investment for manufacturers seeking to enhance their drying processes. As industries continue to evolve, the adoption of advanced technologies like spiral dryer fabric will undoubtedly play a crucial role in shaping the future of manufacturing efficiency.

Improved Product Quality

In the realm of manufacturing, the quality of the final product is paramount, and one of the critical components that significantly influences this quality is the industrial spiral dryer fabric. This specialized fabric plays a vital role in the drying process, which is essential for various industries, including food processing, textiles, and paper production. By facilitating efficient moisture removal, industrial spiral dryer fabric contributes to improved product quality in several ways.

Firstly, the design of spiral dryer fabric allows for uniform drying across the entire surface of the material being processed. Unlike traditional drying methods that may lead to uneven moisture distribution, the spiral configuration ensures that every part of the product is exposed to the drying medium consistently. This uniformity is crucial, as it prevents issues such as warping, discoloration, or the development of undesirable textures that can arise from uneven drying. Consequently, manufacturers can achieve a higher standard of quality in their products, meeting or exceeding customer expectations.

Moreover, the material composition of industrial spiral dryer fabric is engineered to withstand high temperatures and resist wear and tear. This durability not only extends the lifespan of the fabric itself but also ensures that the drying process remains efficient over time. When the fabric maintains its integrity, it minimizes the risk of contamination or defects that could compromise product quality. For instance, in the food industry, any foreign particles or residues from degraded fabric can lead to significant quality control issues, potentially resulting in product recalls or damage to brand reputation. Therefore, the robust nature of spiral dryer fabric is instrumental in safeguarding the quality of the end product.

In addition to enhancing uniformity and durability, industrial spiral dryer fabric also promotes energy efficiency during the drying process. By optimizing airflow and heat transfer, this fabric allows for quicker moisture removal, which not only speeds up production times but also reduces energy consumption. Lower energy usage translates to cost savings for manufacturers, enabling them to allocate resources more effectively while maintaining high-quality standards. Furthermore, energy-efficient processes often align with sustainability goals, appealing to environmentally conscious consumers and stakeholders.

Another significant benefit of using industrial spiral dryer fabric is its adaptability to various manufacturing processes. The fabric can be customized to suit specific applications, whether it involves drying delicate textiles or robust paper products. This versatility ensures that manufacturers can achieve optimal drying conditions tailored to their unique requirements, further enhancing product quality. By selecting the appropriate fabric for their specific needs, companies can mitigate risks associated with product defects and improve overall operational efficiency.

Finally, the integration of advanced technologies in the design of industrial spiral dryer fabric has led to innovations that further enhance product quality. For instance, some fabrics are now equipped with moisture sensors that provide real-time feedback on drying conditions. This capability allows manufacturers to make immediate adjustments to the drying process, ensuring that products are dried to the desired specifications. Such technological advancements not only improve the consistency of the final product but also empower manufacturers to maintain stringent quality control measures.

In conclusion, the use of industrial spiral dryer fabric in manufacturing offers numerous benefits that directly contribute to improved product quality. From ensuring uniform drying and enhancing durability to promoting energy efficiency and adaptability, this specialized fabric plays a crucial role in the overall manufacturing process. As industries continue to prioritize quality and efficiency, the significance of industrial spiral dryer fabric will undoubtedly remain a key factor in achieving excellence in production.

Cost-Effective Operation

In the realm of manufacturing, the efficiency and effectiveness of production processes are paramount, particularly in industries that rely heavily on drying operations. One of the pivotal components that contribute to the optimization of these processes is the industrial spiral dryer fabric. This specialized fabric plays a crucial role in enhancing the cost-effectiveness of operations, thereby providing manufacturers with significant advantages.

To begin with, the design of industrial spiral dryer fabrics is inherently conducive to energy savings. These fabrics are engineered to facilitate the efficient transfer of heat and moisture, which is essential in drying applications. By maximizing the surface area available for heat exchange, spiral dryer fabrics enable a more uniform and rapid drying process. Consequently, this efficiency translates into reduced energy consumption, allowing manufacturers to lower their operational costs. As energy prices continue to fluctuate, the ability to minimize energy usage becomes increasingly vital for maintaining competitive pricing in the market.

Moreover, the durability of industrial spiral dryer fabrics contributes to their cost-effective operation. These fabrics are typically constructed from high-quality materials that withstand the rigors of continuous use in demanding environments. Their resistance to wear and tear means that manufacturers can expect a longer lifespan from their dryer fabrics, reducing the frequency and costs associated with replacements. This longevity not only minimizes downtime in production but also allows for better budgeting and financial planning, as companies can allocate resources more effectively over time.

In addition to energy savings and durability, the maintenance requirements of industrial spiral dryer fabrics are relatively low. This aspect is particularly beneficial for manufacturers seeking to streamline their operations. With less frequent maintenance needs, companies can allocate their workforce more efficiently, focusing on core production activities rather than on upkeep. Furthermore, the ease of cleaning these fabrics ensures that they remain in optimal condition, which is essential for maintaining product quality. By reducing the time and resources spent on maintenance, manufacturers can further enhance their overall productivity and profitability.

Transitioning from operational efficiency to the broader economic implications, the cost-effectiveness of industrial spiral dryer fabrics can also be seen in their impact on product quality. A consistent and reliable drying process is crucial for ensuring that the final products meet quality standards. When drying is performed efficiently, it minimizes the risk of defects and inconsistencies, which can lead to costly rework or waste. By investing in high-quality spiral dryer fabrics, manufacturers not only enhance their operational efficiency but also safeguard their reputation for delivering superior products.

Furthermore, the adaptability of industrial spiral dryer fabrics to various manufacturing processes adds another layer of cost-effectiveness. These fabrics can be tailored to meet the specific needs of different industries, whether it be food processing, textiles, or paper production. This versatility allows manufacturers to optimize their drying processes without the need for extensive modifications to existing equipment, thereby saving both time and money.

In conclusion, the integration of industrial spiral dryer fabrics into manufacturing processes offers a multitude of cost-effective benefits. From energy savings and durability to low maintenance requirements and enhanced product quality, these fabrics play a vital role in streamlining operations and improving profitability. As manufacturers continue to seek ways to optimize their processes in an increasingly competitive landscape, the strategic use of industrial spiral dryer fabrics will undoubtedly remain a key consideration in achieving operational excellence.