Key Differences Between Ultipleat High Flow and Traditional Filters

Efficiency

In the world of industrial filtration, choosing the right filter for your specific application is crucial to ensuring optimal performance and efficiency. Two popular options in the market are Ultipleat High Flow filters and traditional filters. While both serve the purpose of removing contaminants from fluids, there are key differences between the two that can impact their efficiency and effectiveness.

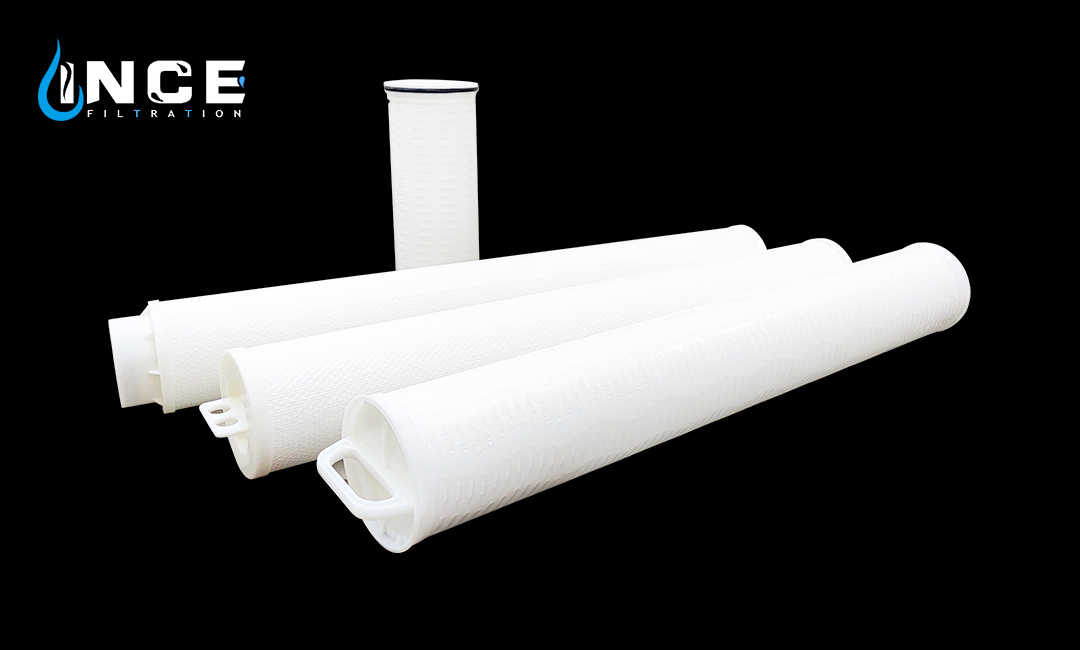

One of the main differences between Ultipleat High Flow filters and traditional filters is their design. Traditional filters typically consist of a single filter element, which means that the fluid has to pass through a relatively small surface area, leading to higher pressure drops and reduced flow rates. On the other hand, Ultipleat High Flow filters feature multiple filter elements within a single housing, providing a larger filtration area and allowing for higher flow rates with lower pressure drops.

This design difference has a direct impact on the efficiency of the two types of filters. Ultipleat High Flow filters are able to handle higher flow rates while maintaining a low pressure drop, which means that they can effectively remove contaminants from fluids without compromising the overall system performance. Traditional filters, on the other hand, may struggle to keep up with high flow rates and can lead to increased energy consumption and maintenance costs.

Another key difference between Ultipleat High Flow filters and traditional filters is their dirt-holding capacity. Ultipleat High Flow filters are designed to hold a larger amount of contaminants before needing to be replaced or cleaned, thanks to their multiple filter elements and larger surface area. This can result in longer service intervals and reduced downtime for maintenance, ultimately leading to cost savings for the user.

In contrast, traditional filters may have a limited dirt-holding capacity, which means that they may need to be replaced or cleaned more frequently. This can result in increased maintenance costs and downtime, as well as potential risks of system failure if the filter becomes overloaded with contaminants.

Additionally, Ultipleat High Flow filters are designed to be more robust and durable compared to traditional filters. The multiple filter elements within a single housing provide added strength and stability, making them suitable for high-pressure and high-temperature applications. Traditional filters, on the other hand, may be more prone to failure under extreme operating conditions, leading to potential system downtime and costly repairs.

Overall, the key differences between Ultipleat High Flow filters and traditional filters lie in their design, efficiency, dirt-holding capacity, and durability. Ultipleat High Flow filters offer superior performance in terms of flow rates, pressure drops, and maintenance intervals, making them a preferred choice for many industrial applications. Traditional filters, while still effective in certain applications, may not be able to match the efficiency and durability of Ultipleat High Flow filters. Ultimately, the choice between the two types of filters will depend on the specific requirements of your application and the level of performance you are looking to achieve.

Flow Rate

When it comes to filtration systems, the choice between Ultipleat High Flow filters and traditional filters can have a significant impact on the efficiency and effectiveness of your operations. One key difference between these two types of filters lies in their flow rates.

Ultipleat High Flow filters are designed to handle a much higher flow rate compared to traditional filters. This is due to their unique design, which features a larger surface area and fewer flow restrictions. As a result, Ultipleat High Flow filters can process a greater volume of fluid in a shorter amount of time, making them ideal for applications where high flow rates are required.

In contrast, traditional filters typically have a smaller surface area and more flow restrictions, which limits their ability to handle high flow rates. While traditional filters may be sufficient for low to moderate flow applications, they may struggle to keep up with the demands of high flow processes.

The higher flow rate capabilities of Ultipleat High Flow filters offer several advantages. For starters, they can help improve overall system efficiency by reducing the amount of time it takes to filter a given volume of fluid. This can lead to cost savings by minimizing downtime and increasing productivity.

Additionally, the higher flow rates of Ultipleat High Flow filters can also help improve the quality of the filtered fluid. By processing a larger volume of fluid in a shorter amount of time, these filters can more effectively remove contaminants and impurities, resulting in cleaner and purer fluid output.

In contrast, traditional filters may struggle to maintain consistent filtration performance when faced with high flow rates. This can lead to reduced filtration efficiency and compromised fluid quality, which can have negative implications for downstream processes and equipment.

Overall, the key difference in flow rate capabilities between Ultipleat High Flow filters and traditional filters highlights the importance of selecting the right filtration system for your specific application. If you require high flow rates and superior filtration performance, Ultipleat High Flow filters may be the ideal choice for your operations.

In conclusion, the flow rate capabilities of Ultipleat High Flow filters set them apart from traditional filters and make them a preferred choice for applications that demand high flow rates and superior filtration performance. By understanding the key differences between these two types of filters, you can make an informed decision that will help optimize the efficiency and effectiveness of your filtration system.

Maintenance Requirements

When it comes to maintaining industrial filtration systems, understanding the key differences between Ultipleat High Flow filters and traditional filters is crucial. Both types of filters serve the same purpose of removing contaminants from fluids, but they have distinct characteristics that impact their maintenance requirements. By examining these differences, businesses can make informed decisions about which type of filter is best suited for their specific needs.

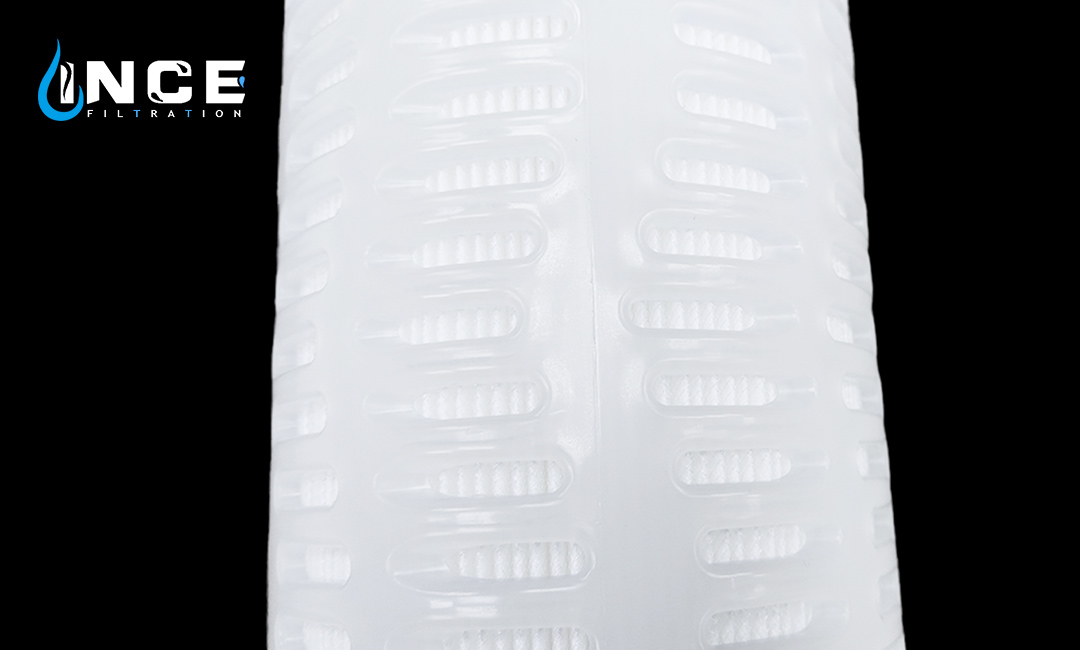

One of the primary differences between Ultipleat High Flow filters and traditional filters is their design. Traditional filters typically consist of a single cartridge or bag that captures contaminants as fluid passes through. These filters have a limited surface area for filtration, which can lead to frequent replacements and increased maintenance costs. In contrast, Ultipleat High Flow filters feature a larger surface area and a unique pleated design that allows for higher flow rates and longer service life. This design reduces the frequency of filter changes and minimizes downtime for maintenance.

Another key difference between Ultipleat High Flow filters and traditional filters is their efficiency in removing contaminants. Traditional filters are effective at capturing larger particles but may struggle to remove smaller particles or achieve high levels of filtration. Ultipleat High Flow filters, on the other hand, are designed to provide superior filtration performance, capturing particles as small as 1 micron with efficiency rates of up to 99.9%. This high level of filtration ensures that fluids remain clean and free of contaminants, reducing the risk of equipment damage and improving overall system performance.

In terms of maintenance requirements, Ultipleat High Flow filters offer several advantages over traditional filters. Due to their larger surface area and longer service life, Ultipleat High Flow filters require less frequent replacements, reducing maintenance costs and downtime. Additionally, the pleated design of Ultipleat High Flow filters allows for easy cleaning and maintenance, further extending their lifespan and ensuring optimal performance. By contrast, traditional filters may need to be replaced more frequently and can be more challenging to clean and maintain, leading to higher maintenance costs and increased downtime.

When it comes to maintenance requirements, businesses must also consider the ease of installation and replacement for both types of filters. Ultipleat High Flow filters are designed for quick and easy installation, with a simple twist-and-lock mechanism that allows for fast and efficient filter changes. This ease of installation reduces the time and labor required for maintenance, minimizing disruptions to operations and ensuring that filtration systems remain up and running. Traditional filters, on the other hand, may be more complex to install and replace, requiring additional tools and expertise to ensure proper installation and performance.

In conclusion, understanding the key differences between Ultipleat High Flow filters and traditional filters is essential for businesses looking to optimize their maintenance requirements. Ultipleat High Flow filters offer superior filtration performance, longer service life, and easier maintenance compared to traditional filters. By choosing the right filter for their specific needs, businesses can reduce maintenance costs, minimize downtime, and ensure that their filtration systems operate at peak efficiency. Ultimately, investing in high-quality filters like Ultipleat High Flow can lead to significant cost savings and improved system performance in the long run.