Key Features of a High Flow Filter Element Explained

Benefits of Using High Flow Filter Elements

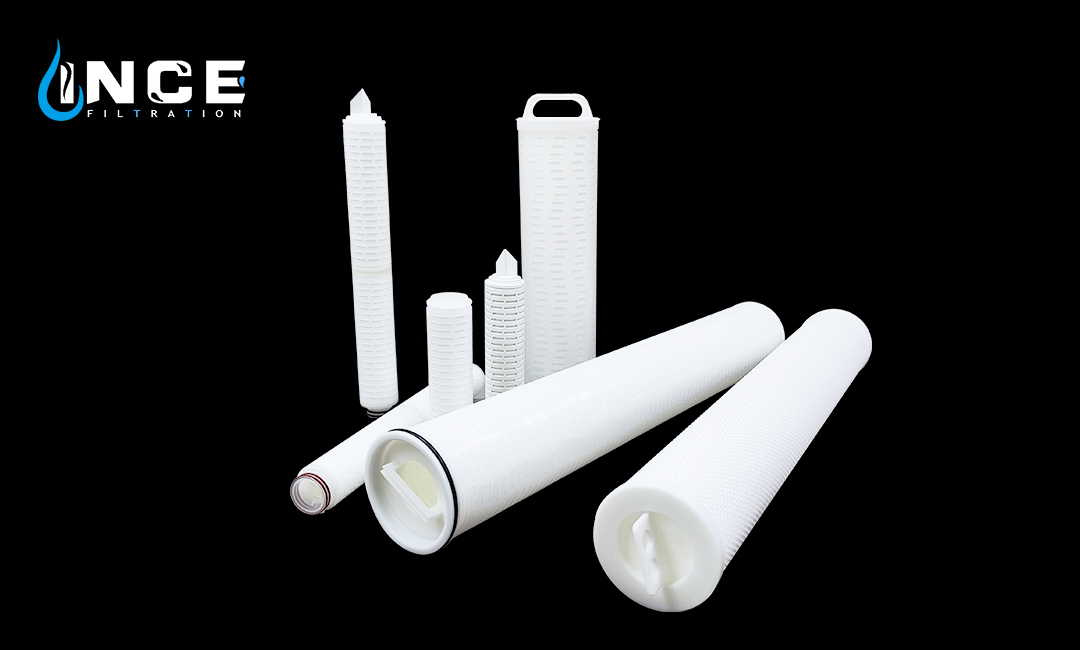

High flow filter elements are an essential component in many industrial processes, providing efficient filtration of liquids and gases to ensure the quality and purity of the final product. These filter elements are designed to handle high flow rates, making them ideal for applications where a large volume of fluid needs to be filtered quickly and effectively.

One key feature of high flow filter elements is their large surface area. This allows for greater contact between the fluid being filtered and the filter media, resulting in more efficient filtration and higher flow rates. The increased surface area also means that high flow filter elements can handle higher dirt loads without becoming clogged, prolonging the life of the filter and reducing maintenance costs.

Another important feature of high flow filter elements is their high dirt-holding capacity. This means that they can capture and retain a large amount of contaminants before needing to be replaced or cleaned. This is particularly beneficial in applications where the fluid being filtered contains a high concentration of dirt or other particles that could potentially damage equipment or affect the quality of the final product.

In addition to their large surface area and high dirt-holding capacity, high flow filter elements are also designed for easy installation and maintenance. Many high flow filter elements are designed to be easily replaceable, allowing for quick and convenient filter changes without the need for specialized tools or equipment. This can help to minimize downtime and ensure that the filtration system remains operational at all times.

High flow filter elements are also available in a variety of materials and configurations to suit different applications and operating conditions. For example, some high flow filter elements are made from stainless steel or other corrosion-resistant materials to withstand harsh chemicals or high temperatures. Others may be designed with pleated filter media to increase surface area and improve filtration efficiency.

Overall, the key features of high flow filter elements make them an essential component in many industrial processes where efficient filtration of liquids and gases is required. Their large surface area, high dirt-holding capacity, and ease of installation and maintenance make them a cost-effective and reliable solution for a wide range of applications.

In conclusion, high flow filter elements offer a number of benefits for industrial processes, including efficient filtration, high flow rates, and easy maintenance. Their key features make them an essential component in many applications where the quality and purity of the final product are paramount. By choosing high flow filter elements that are designed to meet the specific requirements of your application, you can ensure that your filtration system operates at peak performance and delivers consistent results.

Factors to Consider When Choosing a High Flow Filter Element

High flow filter elements are essential components in many industrial processes, helping to remove contaminants and impurities from liquids and gases. When choosing a high flow filter element, there are several key features to consider to ensure optimal performance and efficiency.

One of the most important factors to consider when selecting a high flow filter element is the filtration efficiency. The filtration efficiency of a filter element refers to its ability to remove contaminants of a certain size from the fluid being filtered. High flow filter elements with higher filtration efficiency are able to capture smaller particles, providing cleaner and purer fluids.

Another important feature to consider is the flow rate of the filter element. The flow rate of a filter element determines how quickly it can process a certain volume of fluid. High flow filter elements are designed to handle large volumes of fluid at high flow rates, making them ideal for applications where fast filtration is required.

In addition to filtration efficiency and flow rate, the material of the filter element is also a crucial factor to consider. High flow filter elements are typically made from materials such as stainless steel, polypropylene, or fiberglass, each offering different levels of durability and chemical resistance. The material of the filter element should be chosen based on the specific requirements of the application and the type of fluid being filtered.

Another key feature of a high flow filter element is its design and construction. High flow filter elements are available in various designs, including pleated, wound, and melt-blown, each offering different levels of filtration performance and efficiency. The design of the filter element should be chosen based on the specific requirements of the application and the type of contaminants that need to be removed.

Furthermore, the size and shape of the filter element are also important considerations when choosing a high flow filter element. The size of the filter element should be selected based on the flow rate and volume of fluid that needs to be filtered, while the shape of the filter element should be chosen based on the space constraints of the application.

Additionally, the compatibility of the filter element with the filtration system is another important factor to consider. High flow filter elements should be compatible with the existing filtration system to ensure proper installation and operation. Compatibility issues can lead to leaks, bypassing of contaminants, and reduced filtration efficiency.

Lastly, the cost of the filter element is also an important consideration when choosing a high flow filter element. The cost of the filter element should be weighed against its performance, durability, and efficiency to ensure that it provides value for money.

In conclusion, when choosing a high flow filter element, it is important to consider factors such as filtration efficiency, flow rate, material, design, size, shape, compatibility, and cost. By carefully evaluating these key features, you can select a high flow filter element that meets the specific requirements of your application and provides optimal filtration performance and efficiency.

Maintenance Tips for High Flow Filter Elements

High flow filter elements are an essential component in many industrial processes, helping to remove contaminants and ensure the smooth operation of equipment. Understanding the key features of a high flow filter element is crucial for maintaining optimal performance and prolonging the lifespan of the filter. In this article, we will explore the key features of a high flow filter element and explain their importance in the maintenance of these critical components.

One of the most important features of a high flow filter element is its filtration efficiency. High flow filter elements are designed to remove a wide range of contaminants from the fluid passing through them, including particles, debris, and other impurities. The filtration efficiency of a filter element is typically measured in terms of its micron rating, which indicates the size of particles that the filter can effectively capture. Choosing a high flow filter element with the appropriate micron rating for your specific application is essential for ensuring that it effectively removes contaminants and protects downstream equipment.

Another key feature of a high flow filter element is its flow rate. High flow filter elements are designed to handle large volumes of fluid flow, making them ideal for applications where high flow rates are required. The flow rate of a filter element is typically measured in gallons per minute (GPM) or liters per minute (LPM), and it is important to select a filter element with a flow rate that matches the requirements of your system. Choosing a high flow filter element with a flow rate that is too low can result in reduced efficiency and increased pressure drop, while selecting a filter element with a flow rate that is too high may lead to bypass and inadequate filtration.

In addition to filtration efficiency and flow rate, the material construction of a high flow filter element is another important feature to consider. High flow filter elements are typically made from a variety of materials, including stainless steel, polypropylene, and fiberglass, each offering different levels of durability and compatibility with different fluids. The material construction of a filter element plays a crucial role in its ability to withstand the operating conditions of the system, including temperature, pressure, and chemical compatibility. Selecting a high flow filter element with the appropriate material construction for your specific application is essential for ensuring long-lasting performance and reliable filtration.

Furthermore, the design of a high flow filter element is another key feature that can impact its performance and maintenance requirements. High flow filter elements are available in a variety of designs, including pleated, wound, and depth filters, each offering different levels of filtration efficiency and dirt-holding capacity. The design of a filter element can also impact its ease of installation and maintenance, with some designs requiring more frequent replacement or cleaning than others. Choosing a high flow filter element with a design that is well-suited to your system requirements can help to minimize downtime and maintenance costs while maximizing filtration performance.

In conclusion, understanding the key features of a high flow filter element is essential for maintaining optimal performance and prolonging the lifespan of these critical components. By considering factors such as filtration efficiency, flow rate, material construction, and design, you can select a high flow filter element that meets the requirements of your system and ensures reliable filtration. Regular maintenance and monitoring of your high flow filter elements are also essential for ensuring continued performance and preventing costly downtime. By following these tips and guidelines, you can maximize the efficiency and effectiveness of your high flow filter elements and protect your equipment from contaminants.