Key Features of Spiral Belt Filters for Wastewater Treatment

Efficient Solids Removal

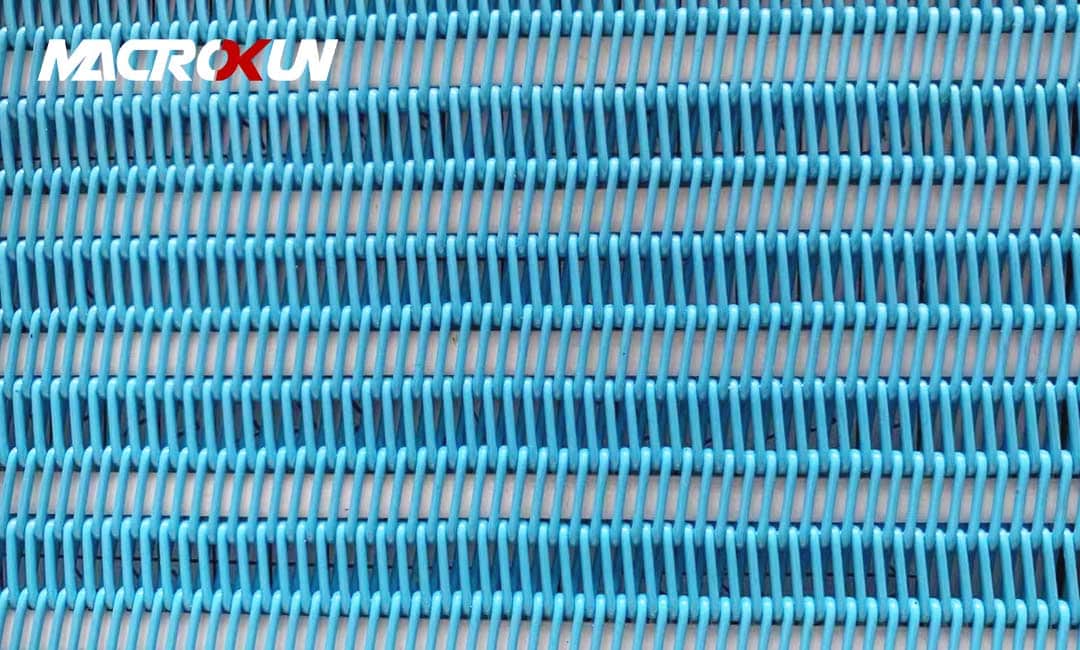

Spiral belt filters have emerged as a pivotal technology in the realm of wastewater treatment, particularly noted for their efficiency in solids removal. These filters operate on a principle that combines mechanical and physical processes to separate solids from liquids effectively. The design of spiral belt filters is characterized by a continuous belt that spirals around a series of rollers, creating a unique filtration surface that enhances the removal of suspended solids. This innovative configuration allows for a larger surface area, which is crucial for capturing and retaining solids as wastewater flows through the system.

One of the key features of spiral belt filters is their ability to handle varying flow rates and solid concentrations. This adaptability is essential in wastewater treatment facilities, where the composition of influent can fluctuate significantly. The spiral design ensures that even at higher flow rates, the filter maintains its efficiency, preventing the clogging that can occur in traditional filtration systems. As a result, operators can rely on spiral belt filters to provide consistent performance, regardless of the incoming wastewater characteristics.

Moreover, the self-cleaning mechanism inherent in spiral belt filters contributes to their effectiveness in solids removal. As the belt moves, it continuously sheds captured solids, which are then transported to a designated discharge point. This process not only minimizes the need for manual cleaning but also reduces downtime, allowing for uninterrupted operation. The self-cleaning feature is particularly advantageous in applications where high solids loading is expected, as it ensures that the filter remains operational without frequent maintenance interventions.

In addition to their mechanical advantages, spiral belt filters are designed with energy efficiency in mind. The operation of these filters typically requires less energy compared to other filtration methods, such as rotary drum filters or conventional clarifiers. This energy efficiency is achieved through the optimized design of the belt and the hydraulic flow patterns within the system. Consequently, wastewater treatment facilities can benefit from lower operational costs while maintaining high standards of solids removal.

Another significant aspect of spiral belt filters is their versatility in application. They can be utilized in various stages of wastewater treatment, including primary, secondary, and even tertiary treatment processes. This flexibility allows facilities to integrate spiral belt filters into existing systems or to design new treatment processes that leverage their unique capabilities. Furthermore, the compact design of these filters makes them suitable for installations where space is limited, providing an effective solution without requiring extensive modifications to existing infrastructure.

The environmental benefits of using spiral belt filters cannot be overlooked. By efficiently removing solids from wastewater, these filters contribute to the overall reduction of pollutants entering natural water bodies. This is particularly important in the context of increasing regulatory pressures on wastewater treatment facilities to improve effluent quality. The effective solids removal achieved by spiral belt filters not only helps facilities comply with stringent discharge standards but also supports broader environmental sustainability goals.

In conclusion, the key features of spiral belt filters, including their efficient solids removal capabilities, adaptability to varying flow conditions, self-cleaning mechanisms, energy efficiency, versatility in application, and environmental benefits, make them an invaluable asset in modern wastewater treatment. As the industry continues to evolve, the adoption of such advanced technologies will play a crucial role in enhancing the effectiveness and sustainability of wastewater management practices. By investing in spiral belt filters, facilities can ensure that they are equipped to meet the challenges of today’s wastewater treatment demands while contributing positively to environmental stewardship.

Versatile Applications in Various Industries

Spiral belt filters have emerged as a pivotal technology in wastewater treatment, offering a range of versatile applications across various industries. These filters are designed to efficiently separate solids from liquids, making them an essential component in processes where the removal of contaminants is crucial. One of the primary advantages of spiral belt filters is their adaptability to different operational environments. They can be utilized in municipal wastewater treatment plants, food processing facilities, and even in the mining sector, showcasing their broad applicability.

In municipal wastewater treatment, spiral belt filters play a significant role in the preliminary treatment phase. They effectively remove large solids and debris from incoming wastewater, thereby protecting downstream equipment from damage and ensuring optimal performance. The design of these filters allows for a continuous flow of water, which enhances their efficiency and reduces the need for manual intervention. This automated process not only saves time but also minimizes labor costs, making it an attractive option for municipalities striving to improve their wastewater management systems.

Moreover, in the food processing industry, spiral belt filters are invaluable for managing by-products and effluents. The food sector generates a substantial amount of wastewater, often laden with organic materials and solids. By employing spiral belt filters, companies can effectively separate these solids, allowing for the recovery of valuable resources and reducing the environmental impact of their operations. This not only aligns with sustainability goals but also helps in complying with stringent regulatory requirements regarding wastewater discharge.

In addition to municipal and food processing applications, the mining industry has also recognized the benefits of spiral belt filters. Mining operations often produce large volumes of wastewater that contain fine particles and contaminants. The use of spiral belt filters in this context facilitates the efficient removal of these solids, thereby improving water quality and enabling the recycling of water within the mining process. This is particularly important in regions where water scarcity is a concern, as it allows for the sustainable use of water resources.

Another noteworthy feature of spiral belt filters is their ability to handle varying flow rates and solid concentrations. This flexibility makes them suitable for both small-scale operations and large industrial applications. The design of the filter can be customized to meet specific requirements, ensuring optimal performance regardless of the operational context. As industries continue to evolve and face new challenges, the adaptability of spiral belt filters positions them as a reliable solution for wastewater treatment.

Furthermore, the maintenance of spiral belt filters is relatively straightforward, which contributes to their appeal across different sectors. Regular cleaning and inspection can be performed with minimal downtime, allowing facilities to maintain continuous operations without significant interruptions. This ease of maintenance is particularly beneficial for industries that operate under tight production schedules, as it helps to minimize the risk of costly delays.

In conclusion, the versatile applications of spiral belt filters in various industries underscore their importance in modern wastewater treatment. Their ability to efficiently separate solids from liquids, coupled with their adaptability to different operational environments, makes them a valuable asset for municipalities, food processing plants, and mining operations alike. As industries increasingly prioritize sustainability and regulatory compliance, the role of spiral belt filters is likely to expand, further solidifying their position as a key technology in the realm of wastewater management.

Low Maintenance and Operational Costs

Spiral belt filters have emerged as a pivotal technology in the realm of wastewater treatment, particularly due to their low maintenance and operational costs. These filters are designed to efficiently separate solids from liquids, making them an essential component in various industrial and municipal applications. One of the most significant advantages of spiral belt filters is their simplicity in design, which inherently reduces the need for extensive maintenance. Unlike traditional filtration systems that may require frequent part replacements or complex cleaning procedures, spiral belt filters utilize a continuous belt mechanism that minimizes wear and tear. This design not only extends the lifespan of the equipment but also ensures that operators spend less time on maintenance tasks, allowing them to focus on other critical aspects of wastewater management.

Moreover, the operational costs associated with spiral belt filters are notably lower than those of many alternative systems. The energy consumption of these filters is relatively minimal, as they often operate using gravity and require less mechanical energy to function effectively. This energy efficiency translates into significant cost savings over time, particularly for facilities that process large volumes of wastewater. Additionally, the materials used in the construction of spiral belt filters are typically durable and resistant to corrosion, further reducing the likelihood of costly repairs or replacements. As a result, facilities can allocate their financial resources more effectively, investing in other areas of their operations while enjoying the benefits of a reliable filtration system.

Another aspect contributing to the low operational costs of spiral belt filters is their ability to handle varying flow rates and solid concentrations. This adaptability means that facilities do not need to invest in multiple filtration systems to accommodate different wastewater characteristics. Instead, a single spiral belt filter can be adjusted to meet the specific needs of the treatment process, thereby streamlining operations and reducing the overall capital expenditure. Furthermore, the ease of operation associated with these filters allows for less specialized training for staff, which can also contribute to lower labor costs. Operators can quickly learn to manage the system, ensuring that the treatment process remains efficient and effective without the need for extensive training programs.

In addition to these financial benefits, the environmental impact of using spiral belt filters is also noteworthy. By effectively removing solids from wastewater, these filters help to reduce the burden on downstream treatment processes, leading to improved overall efficiency in wastewater management. This reduction in the load on subsequent treatment stages not only enhances the quality of the treated effluent but also minimizes the energy and resources required for further processing. Consequently, facilities can achieve compliance with environmental regulations more easily, avoiding potential fines and contributing to a more sustainable approach to wastewater treatment.

In conclusion, the low maintenance and operational costs associated with spiral belt filters make them an attractive option for wastewater treatment facilities. Their simple design, energy efficiency, adaptability to varying conditions, and minimal training requirements all contribute to a cost-effective solution that meets the demands of modern wastewater management. As industries and municipalities continue to seek ways to optimize their operations while adhering to environmental standards, spiral belt filters stand out as a reliable and economical choice, ensuring that the treatment of wastewater is both efficient and sustainable.