Liquid Bag Filter P11S: Key Features and Applications

Key Features of Liquid Bag Filter P11S

The Liquid Bag Filter P11S is a sophisticated filtration solution designed to meet the diverse needs of various industries. One of its most notable features is its robust construction, which ensures durability and longevity even in demanding environments. The filter is typically made from high-quality materials that can withstand harsh chemicals and extreme temperatures, making it suitable for a wide range of applications. This resilience not only enhances the filter’s performance but also reduces the frequency of replacements, ultimately leading to cost savings for users.

Another key feature of the P11S is its high filtration efficiency. The filter is designed to capture particles of varying sizes, ensuring that even the smallest contaminants are effectively removed from the liquid stream. This is particularly important in industries such as pharmaceuticals and food processing, where product purity is paramount. The P11S employs advanced filtration media that maximizes surface area, allowing for greater dirt-holding capacity and extended service life. As a result, users can expect consistent performance and reduced downtime, which is critical for maintaining operational efficiency.

In addition to its efficiency, the Liquid Bag Filter P11S is designed for ease of use. The filter’s bag change-out process is straightforward, allowing operators to quickly replace the filter bags without the need for specialized tools or extensive training. This user-friendly design minimizes the risk of contamination during maintenance and ensures that the filtration system can be quickly restored to optimal performance. Furthermore, the filter’s compact design allows for easy integration into existing systems, making it a versatile choice for various setups.

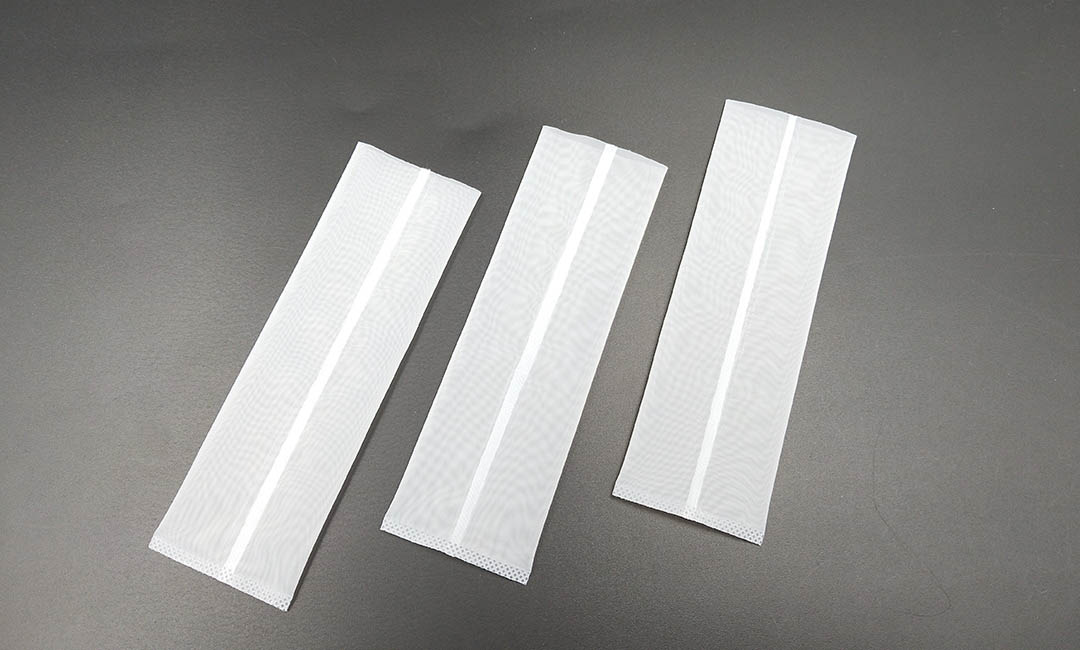

Moreover, the P11S features a wide range of bag sizes and materials, providing users with the flexibility to select the most appropriate options for their specific applications. This adaptability is crucial, as different industries may require different filtration standards based on the nature of the liquids being processed. Whether dealing with water, oils, or chemicals, the P11S can be customized to meet the unique demands of each application, ensuring that users achieve the desired level of filtration.

Another significant advantage of the Liquid Bag Filter P11S is its ability to handle high flow rates. This feature is particularly beneficial for industries that require large volumes of liquid to be filtered in a short amount of time. The filter’s design allows for efficient flow management, reducing the risk of pressure drops and ensuring that the system operates smoothly. Consequently, users can maintain productivity without compromising on the quality of the filtered liquid.

Additionally, the P11S is equipped with features that enhance its operational safety. The filter is designed to minimize the risk of leaks and spills, which is essential in environments where hazardous materials are handled. This focus on safety not only protects personnel but also helps to maintain compliance with industry regulations.

In conclusion, the Liquid Bag Filter P11S stands out due to its robust construction, high filtration efficiency, user-friendly design, and adaptability to various applications. Its ability to handle high flow rates while ensuring safety and compliance makes it an invaluable asset across multiple industries. As businesses continue to prioritize efficiency and product quality, the P11S offers a reliable solution that meets these critical demands, ultimately contributing to improved operational performance and cost-effectiveness.

Applications of Liquid Bag Filter P11S in Industrial Processes

Liquid bag filters are essential components in industrial processes where the removal of contaminants from liquids is necessary. One such filter that has gained popularity in various industries is the Liquid Bag Filter P11S. This article will explore the key features of the Liquid Bag Filter P11S and its applications in industrial processes.

The Liquid Bag Filter P11S is designed to effectively remove solid particles and contaminants from liquids, ensuring a clean and pure end product. One of the key features of this filter is its high dirt-holding capacity, which allows it to capture a large volume of contaminants before needing to be replaced. This feature is particularly beneficial in industries where the liquid being filtered contains a high concentration of solid particles.

Another important feature of the Liquid Bag Filter P11S is its ease of installation and maintenance. The filter is designed for quick and simple installation, allowing for minimal downtime during the setup process. Additionally, the filter is easy to clean and replace, reducing maintenance costs and ensuring optimal performance over time.

The Liquid Bag Filter P11S is also known for its high efficiency in removing contaminants from liquids. The filter is designed with a high-quality filtration media that effectively captures particles of various sizes, ensuring that the filtered liquid meets the required purity standards. This high efficiency makes the Liquid Bag Filter P11S a reliable choice for industries where the quality of the end product is crucial.

In terms of applications, the Liquid Bag Filter P11S is widely used in a variety of industrial processes. One common application is in the food and beverage industry, where the filter is used to remove impurities from liquids such as juices, syrups, and sauces. By ensuring that the final product is free from contaminants, the Liquid Bag Filter P11S helps maintain the quality and safety of food and beverage products.

The Liquid Bag Filter P11S is also commonly used in the pharmaceutical industry, where the purity of liquids is of utmost importance. The filter is used to remove particles and impurities from pharmaceutical solutions, ensuring that medications and other products meet strict quality standards. Additionally, the high efficiency of the filter helps reduce the risk of contamination and ensures the safety of pharmaceutical products.

In the chemical industry, the Liquid Bag Filter P11S is used to filter various liquids, including solvents, acids, and other chemicals. The filter helps remove impurities and contaminants from these liquids, ensuring that they meet the required purity levels for use in manufacturing processes. By maintaining the cleanliness of these liquids, the filter helps prevent equipment damage and ensures the efficiency of chemical processes.

Overall, the Liquid Bag Filter P11S is a versatile and reliable filtration solution for a wide range of industrial applications. With its high dirt-holding capacity, ease of installation and maintenance, and high efficiency in removing contaminants, the filter is an essential component in industries where liquid purity is critical. Whether used in the food and beverage, pharmaceutical, or chemical industry, the Liquid Bag Filter P11S delivers consistent and reliable performance, making it a valuable asset for any industrial process.

Advantages of Using Liquid Bag Filter P11S Over Traditional Filters

The Liquid Bag Filter P11S represents a significant advancement in filtration technology, offering numerous advantages over traditional filters. One of the primary benefits of the P11S is its enhanced filtration efficiency. Traditional filters often rely on a single layer of media, which can lead to uneven filtration and the potential for particles to bypass the filter. In contrast, the P11S utilizes a multi-layered bag design that captures a wider range of particle sizes, ensuring that even the smallest contaminants are effectively removed from the liquid stream. This increased efficiency not only improves the quality of the filtered liquid but also extends the lifespan of downstream equipment by preventing the accumulation of harmful particles.

Another notable advantage of the Liquid Bag Filter P11S is its ease of maintenance. Traditional filters often require complex disassembly and reassembly processes, which can be time-consuming and labor-intensive. The P11S, however, is designed for quick and straightforward bag replacement, allowing operators to perform maintenance tasks with minimal downtime. This user-friendly design is particularly beneficial in industrial settings where operational efficiency is critical. By reducing the time and effort required for maintenance, the P11S helps facilities maintain consistent production levels while minimizing the risk of contamination.

In addition to its operational efficiency, the Liquid Bag Filter P11S is also more environmentally friendly compared to traditional filters. Many conventional filtration systems rely on disposable filter media that contribute to waste generation. The P11S, on the other hand, can be equipped with reusable filter bags, significantly reducing the amount of waste produced. This sustainability aspect is increasingly important in today’s environmentally conscious market, where companies are seeking ways to minimize their ecological footprint. By opting for the P11S, organizations can not only improve their filtration processes but also align with broader sustainability goals.

Furthermore, the P11S offers versatility in its applications. Traditional filters may be limited in the types of liquids they can process, often requiring different systems for various applications. The Liquid Bag Filter P11S, however, is designed to handle a wide range of liquids, including viscous fluids, chemicals, and even food-grade products. This adaptability makes it an ideal choice for industries such as pharmaceuticals, food and beverage, and chemical processing, where diverse filtration needs must be met without compromising on quality or safety.

Cost-effectiveness is another compelling advantage of the Liquid Bag Filter P11S. While the initial investment may be higher than that of traditional filters, the long-term savings associated with reduced maintenance costs, extended equipment life, and lower waste disposal fees can make the P11S a more economical choice over time. Additionally, the improved filtration efficiency can lead to better product quality, which may enhance customer satisfaction and reduce costs associated with product recalls or reprocessing.

In conclusion, the Liquid Bag Filter P11S offers a range of advantages over traditional filters, including enhanced filtration efficiency, ease of maintenance, environmental sustainability, versatility in applications, and cost-effectiveness. These features make the P11S an attractive option for industries seeking reliable and efficient filtration solutions. As companies continue to prioritize quality and sustainability, the P11S stands out as a modern solution that meets the demands of today’s filtration challenges while paving the way for future advancements in the field.

Maintenance Tips for Liquid Bag Filter P11S

Liquid bag filters are essential components in many industrial processes, helping to remove contaminants and impurities from liquids to ensure product quality and equipment longevity. One popular option in the market is the Liquid Bag Filter P11S, known for its efficiency and reliability. In this article, we will explore the key features and applications of the Liquid Bag Filter P11S, as well as provide some maintenance tips to ensure optimal performance.

The Liquid Bag Filter P11S is designed with a high-quality stainless steel housing, making it durable and resistant to corrosion. This ensures a long service life and minimal maintenance requirements, saving time and money for the user. The filter also features a top inlet design, allowing for easy installation and replacement of filter bags. This design simplifies the maintenance process and reduces downtime, making it a convenient choice for busy industrial settings.

Another key feature of the Liquid Bag Filter P11S is its high filtration efficiency. The filter bags used in this system are made of high-quality materials that can capture even the smallest particles and contaminants, ensuring that the filtered liquid meets the required quality standards. This high filtration efficiency is crucial in industries such as food and beverage, pharmaceuticals, and electronics, where product purity is of utmost importance.

The Liquid Bag Filter P11S is versatile and can be used in a wide range of applications. It is commonly used in the filtration of water, chemicals, oils, and other liquids in various industries. The filter can handle high flow rates and pressures, making it suitable for demanding industrial processes. Whether you need to remove solid particles, oils, or other impurities from your liquid stream, the Liquid Bag Filter P11S can deliver reliable performance.

To ensure optimal performance and longevity of the Liquid Bag Filter P11S, regular maintenance is essential. Here are some maintenance tips to help you keep your filter in top condition:

1. Regularly inspect the filter housing for any signs of damage or corrosion. Replace any damaged parts immediately to prevent leaks and ensure proper filtration.

2. Check the filter bags regularly for signs of wear or clogging. Replace the filter bags as needed to maintain high filtration efficiency.

3. Clean the filter housing and internal components regularly to remove any accumulated debris or contaminants. This will help prevent clogging and ensure smooth operation of the filter.

4. Monitor the pressure drop across the filter regularly. A sudden increase in pressure drop may indicate a clogged filter bag or a malfunctioning system. Address any issues promptly to prevent damage to the filter and ensure efficient filtration.

By following these maintenance tips, you can ensure that your Liquid Bag Filter P11S continues to deliver reliable performance and high filtration efficiency. Regular maintenance will not only extend the service life of the filter but also help you avoid costly downtime and repairs. Invest in the maintenance of your Liquid Bag Filter P11S to protect your equipment and ensure the quality of your products.