liquid filter bags

The general parameters of liquid filter bags include:

Material: Liquid filter bags are typically made from materials such as polyester, polypropylene, nylon, or felt. The material chosen depends on the specific application and the type of liquid being filtered.

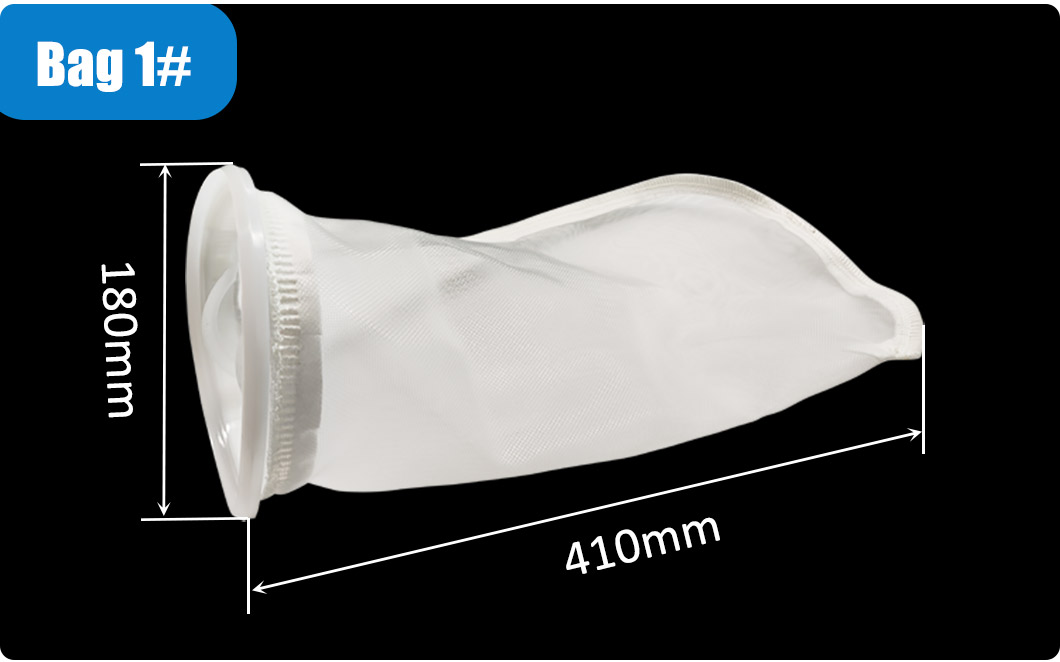

Size: Liquid filter bags come in various sizes to accommodate different filtration requirements. The size is typically specified by the diameter and length of the bag.

Micron rating: The micron rating of a liquid filter bag refers to the size of particles it can effectively capture. It indicates the level of filtration and can range from a few microns to several hundred microns.

Construction: Liquid filter bags are constructed with a top opening for easy installation and removal. They may have a sewn or welded seam to ensure durability and prevent bypass of contaminants.

Filtration efficiency: The filtration efficiency of a liquid filter bag refers to its ability to remove particles of a certain size from the liquid. It is typically expressed as a percentage, indicating the percentage of particles removed.

Flow rate: The flow rate of a liquid filter bag refers to the volume of liquid that can pass through the bag per unit of time. It is influenced by factors such as the size of the bag, the material, and the filtration efficiency.

Pressure rating: Liquid filter bags have a maximum pressure rating that indicates the maximum pressure they can withstand without failure. This parameter is important to ensure the bag can handle the pressure of the liquid being filtered.

Chemical compatibility: The material of the liquid filter bag should be chemically compatible with the liquid being filtered to avoid any degradation or contamination. It is important to consider the compatibility of the bag material with the specific liquid or chemical being filtered.

Operating temperature: Liquid filter bags have a maximum operating temperature that indicates the highest temperature at which they can effectively function without deterioration. This parameter is crucial to ensure the bag can withstand the temperature of the liquid being filtered.

End connections: Liquid filter bags may have different end connections to facilitate their installation and connection to the filtration system. Common types of end connections include sewn-in rings, snap rings, or flanges.

These parameters can vary depending on the specific application and requirements of the liquid filtration process. It is important to consider these parameters when selecting liquid filter bags to ensure optimal filtration performance.

whatsapp:8618032835827

E-Mail: sales4@incefiltration.com