Liquid Filter Bags: Essential for Clean Rosin Extractions

Benefits of Using Liquid Filter Bags in Rosin Extraction

In the realm of rosin extraction, the choice of equipment and materials plays a pivotal role in determining the quality and purity of the final product. Among the various tools available, liquid filter bags have emerged as essential components in the extraction process. These bags, designed specifically for filtering out unwanted particles, offer numerous benefits that significantly enhance the efficiency and effectiveness of rosin extraction.

One of the primary advantages of using liquid filter bags is their ability to provide a high level of filtration. During the rosin extraction process, the goal is to separate the desirable compounds from the plant material, ensuring that only the purest essence is retained. Liquid filter bags are engineered with varying micron ratings, allowing users to select the appropriate level of filtration based on their specific needs. This precision in filtration not only helps in achieving a cleaner product but also minimizes the presence of contaminants that could compromise the quality of the rosin.

Moreover, the use of liquid filter bags can lead to increased yield during the extraction process. By effectively trapping unwanted plant material and other impurities, these bags allow for a more efficient extraction of cannabinoids and terpenes. As a result, users can expect to obtain a higher quantity of rosin from the same amount of starting material. This increased yield not only maximizes the return on investment but also enhances the overall productivity of the extraction process.

In addition to improving yield and purity, liquid filter bags also contribute to a more streamlined extraction process. The design of these bags allows for easy setup and cleanup, which is particularly beneficial in a commercial setting where time is of the essence. Users can quickly load the filter bags with their plant material, perform the extraction, and then dispose of the bags without the need for extensive cleaning. This efficiency not only saves time but also reduces labor costs, making the entire operation more cost-effective.

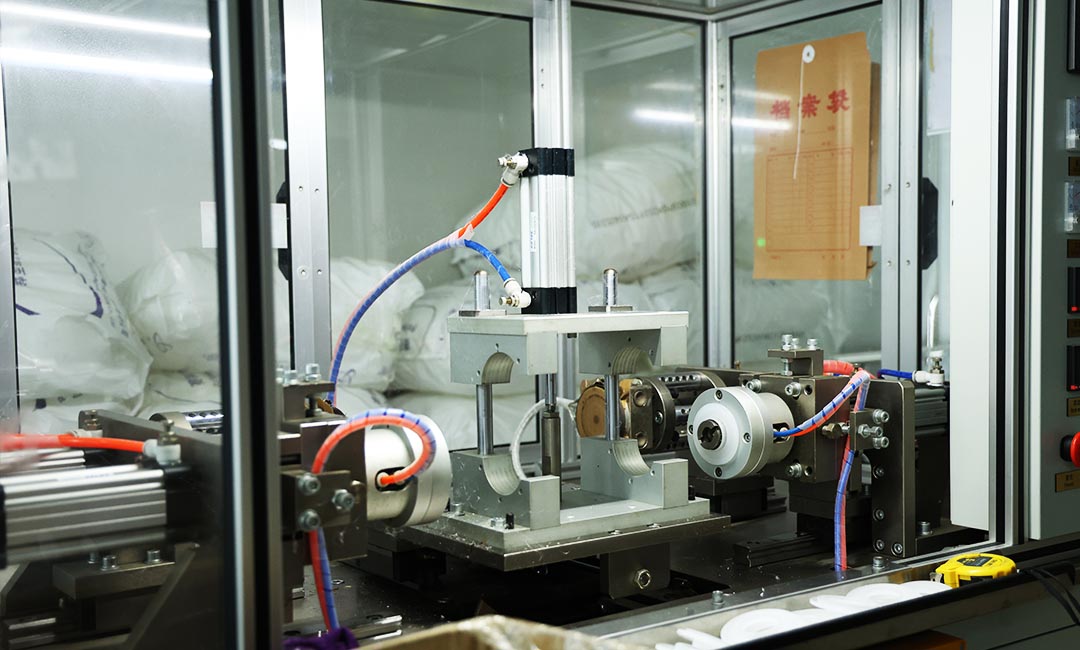

Furthermore, liquid filter bags are versatile and can be used with various extraction methods, including hydraulic presses and pneumatic systems. This adaptability makes them an invaluable tool for both small-scale home extractors and large-scale commercial operations. Regardless of the method employed, the consistent performance of liquid filter bags ensures that users can achieve optimal results across different extraction setups.

Another noteworthy benefit of liquid filter bags is their ability to enhance the flavor and aroma profile of the extracted rosin. By effectively filtering out undesirable plant material, these bags help preserve the delicate terpenes that contribute to the overall sensory experience of the final product. This preservation of flavor and aroma is particularly important for consumers who seek high-quality rosin that delivers a rich and enjoyable experience.

In conclusion, the benefits of using liquid filter bags in rosin extraction are manifold. From providing superior filtration and increasing yield to streamlining the extraction process and enhancing the flavor profile, these bags are indispensable tools for anyone involved in the production of rosin. As the demand for high-quality extracts continues to grow, the importance of utilizing effective filtration methods cannot be overstated. By incorporating liquid filter bags into their extraction processes, producers can ensure that they are delivering a clean, potent, and flavorful product that meets the expectations of discerning consumers.

How to Choose the Right Liquid Filter Bag for Your Needs

When it comes to achieving clean rosin extractions, the choice of liquid filter bags is paramount. These bags serve as a crucial component in the extraction process, ensuring that the final product is free from unwanted contaminants and impurities. Selecting the right liquid filter bag involves several considerations that can significantly impact the quality of the extraction. Understanding these factors will help you make an informed decision tailored to your specific needs.

First and foremost, the micron size of the filter bag is a critical aspect to consider. Micron size refers to the size of the pores in the bag, which determines what particles can pass through during the extraction process. For rosin extraction, bags typically range from 25 to 220 microns. A smaller micron size, such as 25 or 45 microns, is ideal for capturing finer particles and ensuring a cleaner product. Conversely, larger micron sizes, like 160 or 220 microns, may be more suitable for coarser materials, allowing for a quicker extraction process while still filtering out larger contaminants. Therefore, assessing the type of material you are working with and the desired purity of the final product will guide you in selecting the appropriate micron size.

In addition to micron size, the material composition of the filter bag is another essential factor. Liquid filter bags are commonly made from nylon, polyester, or polypropylene, each offering distinct advantages. Nylon bags are known for their durability and resistance to heat, making them a popular choice for high-temperature extractions. Polyester bags, on the other hand, are often more affordable and provide good filtration capabilities, while polypropylene bags are lightweight and resistant to various chemicals. Evaluating the specific requirements of your extraction process, including temperature and chemical exposure, will help you determine the most suitable material for your filter bags.

Moreover, the capacity and size of the filter bag should not be overlooked. The size of the bag must correspond to the volume of material you intend to extract. Using a bag that is too small can lead to overfilling, which may compromise the filtration process and result in a lower-quality extract. Conversely, an excessively large bag may lead to inefficient extraction and wasted material. Therefore, it is advisable to choose a bag that fits your extraction setup and allows for optimal flow and filtration.

Furthermore, the design of the filter bag can also influence its effectiveness. Some bags come with features such as reinforced seams or drawstring closures, which enhance their durability and ease of use. A well-constructed bag will not only withstand the rigors of the extraction process but also prevent any leaks or tears that could contaminate the final product. Therefore, investing in high-quality filter bags with thoughtful design elements can significantly enhance your extraction experience.

Lastly, it is beneficial to consider the reputation of the manufacturer when selecting liquid filter bags. Established brands often provide detailed specifications and customer reviews, which can offer insights into the performance and reliability of their products. By choosing reputable manufacturers, you can ensure that you are investing in filter bags that meet industry standards and deliver consistent results.

In conclusion, selecting the right liquid filter bag for rosin extractions involves careful consideration of micron size, material composition, capacity, design, and manufacturer reputation. By taking the time to evaluate these factors, you can enhance the quality of your extractions and achieve cleaner, more refined results. Ultimately, the right filter bag will not only improve the efficiency of your extraction process but also contribute to the overall success of your endeavors in producing high-quality rosin.

Maintenance Tips for Liquid Filter Bags to Ensure Longevity

Liquid filter bags play a crucial role in the process of rosin extraction, serving as a barrier that separates the desired product from unwanted impurities. To ensure that these bags perform optimally and last for multiple uses, proper maintenance is essential. By following a few key maintenance tips, users can extend the lifespan of their liquid filter bags while maintaining the quality of their rosin extractions.

First and foremost, it is vital to clean the filter bags immediately after use. Residue left to dry can become increasingly difficult to remove, potentially compromising the integrity of the bag. A gentle rinse with warm water is often sufficient to remove most of the material. However, for more stubborn residues, a mild detergent can be employed. It is important to avoid harsh chemicals or abrasive materials, as these can damage the fabric and reduce the bag’s effectiveness. After rinsing, the bags should be thoroughly dried, either air-drying or using a low-heat setting in a dryer, as high temperatures can warp the material.

In addition to regular cleaning, users should also inspect their liquid filter bags for any signs of wear and tear. Over time, the fabric may develop small holes or frays that can compromise filtration efficiency. Regular inspections allow for early detection of such issues, enabling users to replace damaged bags before they affect the quality of the extraction. It is advisable to keep a close eye on the seams and stitching, as these areas are often the first to show signs of stress.

Another important aspect of maintenance is proper storage. When not in use, liquid filter bags should be stored in a cool, dry place away from direct sunlight. Prolonged exposure to UV rays can degrade the fabric, leading to a decrease in performance. Additionally, it is best to avoid folding the bags in a way that creates creases, as this can weaken the material over time. Instead, consider hanging the bags or storing them flat to maintain their shape and integrity.

Furthermore, users should be mindful of the type of materials being filtered. Different extraction processes may require different types of filter bags, and using the wrong type can lead to premature wear. For instance, bags designed for coarse materials may not hold up well when used with finer substances. Therefore, it is essential to select the appropriate filter bag for each specific application to ensure optimal performance and longevity.

Lastly, it is beneficial to keep a log of usage and maintenance activities. By tracking how often each bag is used and when it was last cleaned or inspected, users can develop a better understanding of their lifespan and performance. This proactive approach not only aids in timely replacements but also helps in identifying patterns that may indicate the need for adjustments in the extraction process.

In conclusion, maintaining liquid filter bags is a straightforward yet vital aspect of ensuring clean rosin extractions. By implementing regular cleaning routines, conducting thorough inspections, storing bags properly, selecting the right materials, and keeping detailed records, users can significantly enhance the longevity and effectiveness of their filter bags. Ultimately, these practices contribute to a more efficient extraction process, yielding higher-quality rosin while minimizing waste and maximizing the value of each extraction session.

Common Mistakes to Avoid When Using Liquid Filter Bags in Extraction

When utilizing liquid filter bags in the extraction of rosin, it is crucial to understand the common mistakes that can compromise the quality of the final product. One of the most prevalent errors is the selection of the wrong micron size for the filter bags. Micron size plays a significant role in determining the clarity and purity of the extracted rosin. Using a filter bag with a micron size that is too large can allow unwanted plant material and contaminants to pass through, resulting in a product that is less refined and potentially harsher on the palate. Conversely, using a filter bag with a micron size that is too small can lead to clogging, which not only slows down the extraction process but can also cause a decrease in yield.

Another common mistake is improper bag handling during the extraction process. It is essential to ensure that the filter bags are securely fastened and properly positioned within the extraction setup. If the bags are not adequately secured, they may shift or tear, leading to contamination of the rosin with unwanted materials. Additionally, overfilling the bags can create excessive pressure, which may also result in tears or leaks. Therefore, it is advisable to fill the bags to a recommended capacity, allowing enough space for the material to expand during the extraction process.

Temperature control is another critical factor that can significantly impact the quality of rosin extraction. Many individuals overlook the importance of maintaining the appropriate temperature throughout the extraction process. Excessive heat can degrade the terpenes and cannabinoids, leading to a loss of flavor and potency. On the other hand, insufficient heat may result in a lower yield and a less effective extraction. It is essential to monitor and adjust the temperature carefully, ensuring that it remains within the optimal range for the specific material being processed.

Moreover, timing is a crucial element that should not be underestimated. Many extractors make the mistake of either rushing the extraction process or allowing it to take too long. Rushing can lead to incomplete extraction, while prolonged extraction can result in the leaching of undesirable compounds. It is vital to find a balance, allowing enough time for the extraction to occur without overextending the process. This balance can be achieved through careful observation and experience, as each batch may require slight adjustments based on the material and conditions.

Furthermore, neglecting to clean the filter bags properly after each use is a mistake that can have long-term consequences. Residual plant material and oils can accumulate in the bags, leading to cross-contamination in future extractions. This not only affects the flavor and quality of the rosin but can also introduce unwanted impurities. Therefore, it is essential to thoroughly clean and dry the filter bags after each use, ensuring they are in optimal condition for the next extraction.

Lastly, failing to document the extraction process can hinder the ability to replicate successful results. Keeping detailed records of the micron sizes used, temperatures, times, and any other relevant variables allows for a more systematic approach to extraction. This documentation can help identify what works best and what adjustments may be necessary for future extractions. By avoiding these common mistakes, extractors can significantly enhance the quality of their rosin, ensuring a cleaner, more potent product that meets the expectations of consumers.