Maintenance Made Easy: How to Clean and Care for High Flow Pleated Filters

Benefits of High Flow Pleated Filters

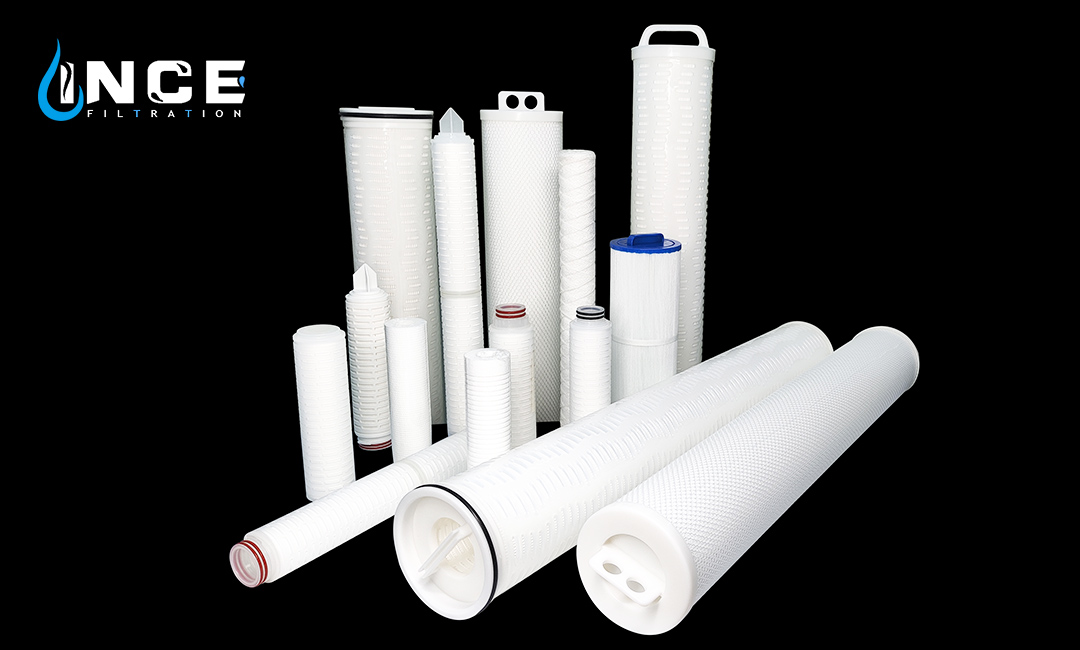

High flow pleated filters are an essential component of many industrial and commercial filtration systems. These filters are designed to handle high flow rates while still providing effective filtration of contaminants. They offer a number of benefits over traditional filters, including increased efficiency, longer service life, and reduced maintenance requirements. In order to maximize the performance and lifespan of high flow pleated filters, proper cleaning and maintenance are essential.

One of the key benefits of high flow pleated filters is their increased efficiency. These filters are designed with a larger surface area than traditional filters, allowing them to capture more contaminants and provide better filtration. This increased efficiency not only improves the quality of the filtered water or air, but also reduces the strain on the filtration system as a whole. By regularly cleaning and maintaining high flow pleated filters, you can ensure that they continue to operate at peak efficiency and provide the best possible filtration.

Another benefit of high flow pleated filters is their longer service life. Because these filters are designed to handle high flow rates, they are more durable and can withstand greater wear and tear than traditional filters. With proper cleaning and maintenance, high flow pleated filters can last for years without needing to be replaced. This not only saves money on filter replacements, but also reduces downtime and maintenance costs associated with filter changes.

In addition to increased efficiency and longer service life, high flow pleated filters also require less maintenance than traditional filters. Because of their larger surface area and durable construction, these filters can go longer between cleanings and replacements. However, regular maintenance is still important to ensure that the filters continue to operate effectively. By following a few simple steps, you can keep your high flow pleated filters in top condition and avoid costly repairs or replacements.

To clean high flow pleated filters, start by turning off the filtration system and removing the filter from its housing. Use a soft brush or cloth to gently remove any visible debris or contaminants from the filter surface. Be careful not to damage the pleats or tear the filter material. Once the filter is free of debris, rinse it thoroughly with clean water to remove any remaining particles. Allow the filter to dry completely before reinstalling it in the filtration system.

In addition to regular cleaning, it is important to inspect high flow pleated filters periodically for signs of wear or damage. Check the filter material for tears, holes, or other defects that could affect its performance. Inspect the pleats for any signs of clogging or blockages that could reduce flow rates. If you notice any issues with the filter, replace it immediately to prevent damage to the filtration system.

By following these simple steps, you can keep your high flow pleated filters clean and well-maintained, ensuring that they continue to provide effective filtration for years to come. With their increased efficiency, longer service life, and reduced maintenance requirements, high flow pleated filters are an excellent choice for industrial and commercial filtration systems. Take care of your filters, and they will take care of you.

Step-by-Step Guide to Cleaning High Flow Pleated Filters

High flow pleated filters are an essential component of many industrial and commercial filtration systems. These filters are designed to handle high flow rates while still providing effective filtration of particles and contaminants. To ensure that your high flow pleated filters continue to perform at their best, regular cleaning and maintenance are essential. In this article, we will provide you with a step-by-step guide on how to clean and care for high flow pleated filters.

The first step in cleaning high flow pleated filters is to shut off the system and allow it to cool down. This will prevent any accidents or injuries while you are working on the filters. Once the system has cooled down, carefully remove the filters from their housing. Be sure to handle the filters with care to avoid damaging them.

Next, inspect the filters for any visible signs of damage or wear. Look for tears, holes, or other damage that could affect the performance of the filters. If you notice any damage, it may be necessary to replace the filters rather than attempting to clean them.

To clean the filters, start by gently tapping them to dislodge any loose debris or particles. You can also use a soft brush or vacuum cleaner to remove any surface dirt or dust. Be careful not to apply too much pressure, as this could damage the pleats of the filters.

Once you have removed as much surface dirt as possible, it is time to wash the filters. Fill a large container with warm water and add a mild detergent. Place the filters in the water and gently agitate them to help loosen any remaining dirt or contaminants. Allow the filters to soak for a few minutes to ensure thorough cleaning.

After soaking, rinse the filters thoroughly with clean water to remove any detergent residue. You can also use a hose or pressure washer to help remove stubborn dirt or debris. Be sure to rinse the filters from the clean side to the dirty side to prevent pushing contaminants back into the filter media.

Once the filters are clean, allow them to air dry completely before reinstalling them in the housing. Avoid using heat or direct sunlight to dry the filters, as this could cause damage to the filter media. Once the filters are dry, carefully reinstall them in the housing and secure them in place.

Finally, restart the system and check for any leaks or issues with the filters. Monitor the performance of the filters to ensure that they are providing effective filtration and maintaining proper flow rates. If you notice any issues, it may be necessary to repeat the cleaning process or replace the filters.

In conclusion, regular cleaning and maintenance are essential for ensuring the optimal performance of high flow pleated filters. By following the steps outlined in this guide, you can keep your filters clean and well-maintained, allowing them to continue providing effective filtration for your system. Remember to inspect the filters regularly and address any issues promptly to prevent damage and ensure the longevity of your filters.

Importance of Regular Maintenance for High Flow Pleated Filters

High flow pleated filters are an essential component of many industrial and commercial filtration systems. These filters are designed to handle high flow rates while effectively removing contaminants from the air or liquid being filtered. However, in order for high flow pleated filters to continue operating at peak efficiency, regular maintenance is crucial.

Regular maintenance of high flow pleated filters is important for several reasons. First and foremost, proper maintenance helps to ensure that the filter is able to effectively remove contaminants from the air or liquid being filtered. Over time, dirt, dust, and other particles can accumulate on the surface of the filter, reducing its ability to capture contaminants. By regularly cleaning and caring for high flow pleated filters, you can help to maintain their effectiveness and prolong their lifespan.

In addition to ensuring optimal filtration performance, regular maintenance of high flow pleated filters can also help to prevent damage to the filter itself. When filters become clogged with dirt and debris, the pressure differential across the filter can increase, putting additional strain on the filter material. This can lead to tears or other damage to the filter, compromising its ability to effectively filter contaminants. By regularly cleaning and caring for high flow pleated filters, you can help to prevent damage and extend the life of the filter.

There are several steps you can take to clean and care for high flow pleated filters. The first step is to regularly inspect the filter for signs of dirt or debris buildup. If you notice that the filter is becoming dirty, it is important to clean it as soon as possible to prevent clogging and damage. To clean a high flow pleated filter, you can use a vacuum cleaner or compressed air to remove dirt and debris from the surface of the filter. Be sure to follow the manufacturer’s instructions for cleaning the filter to avoid damaging the filter material.

In addition to regular cleaning, it is also important to replace high flow pleated filters on a regular basis. Over time, the filter material can become worn or damaged, reducing its effectiveness at filtering contaminants. By replacing the filter at regular intervals, you can ensure that your filtration system continues to operate at peak efficiency. Be sure to follow the manufacturer’s recommendations for filter replacement intervals to ensure optimal performance.

In conclusion, regular maintenance of high flow pleated filters is essential for ensuring optimal filtration performance and prolonging the life of the filter. By regularly cleaning and caring for high flow pleated filters, you can help to maintain their effectiveness and prevent damage. Be sure to inspect the filter regularly for signs of dirt or debris buildup, and clean or replace the filter as needed. By following these simple maintenance tips, you can keep your high flow pleated filters operating at peak efficiency for years to come.

Common Mistakes to Avoid When Caring for High Flow Pleated Filters

High flow pleated filters are an essential component of many industrial and commercial filtration systems. These filters are designed to handle high flow rates while effectively removing contaminants from the air or liquid being filtered. Proper maintenance is crucial to ensure that high flow pleated filters continue to perform at their best and provide optimal filtration efficiency. However, there are common mistakes that can be made when caring for these filters that can compromise their performance and longevity.

One of the most common mistakes people make when caring for high flow pleated filters is neglecting regular cleaning and maintenance. Over time, dirt, dust, and other contaminants can build up on the surface of the filter, reducing its effectiveness and causing it to become clogged. This can lead to decreased flow rates, increased pressure drop, and ultimately, a decrease in filtration efficiency. Regular cleaning and maintenance are essential to prevent these issues and ensure that the filter continues to perform at its best.

Another common mistake is using the wrong cleaning methods or products. High flow pleated filters are typically made from durable materials such as polyester or polypropylene, which can be damaged by harsh chemicals or abrasive cleaning methods. It is important to use gentle cleaning solutions and techniques that are specifically designed for use with high flow pleated filters. Avoid using bleach, ammonia, or other harsh chemicals, as these can degrade the filter material and reduce its effectiveness.

It is also important to avoid using excessive force when cleaning high flow pleated filters. While it may be tempting to scrub or agitate the filter to remove stubborn dirt or debris, this can actually cause damage to the filter material and reduce its lifespan. Instead, gently rinse the filter with water and use a soft brush or cloth to remove any remaining contaminants. Avoid using high-pressure water or compressed air, as this can also damage the filter material and compromise its performance.

Another common mistake is failing to properly dry the filter after cleaning. Moisture can become trapped in the filter material, leading to mold or mildew growth and reducing filtration efficiency. After cleaning, allow the filter to air dry completely before reinstalling it in the filtration system. If necessary, use a fan or dehumidifier to speed up the drying process. Avoid using heat sources such as hair dryers or ovens, as these can damage the filter material.

In conclusion, proper maintenance is essential to ensure that high flow pleated filters continue to perform at their best and provide optimal filtration efficiency. By avoiding common mistakes such as neglecting regular cleaning, using the wrong cleaning methods or products, applying excessive force, and failing to properly dry the filter, you can extend the lifespan of your filter and maintain its performance over time. Remember to follow the manufacturer’s recommendations for cleaning and maintenance, and consult a professional if you have any questions or concerns about caring for your high flow pleated filters.