Maximize Filtration Power with PP Pleated Cartridges

Benefits of Using PP Pleated Cartridges for Filtration

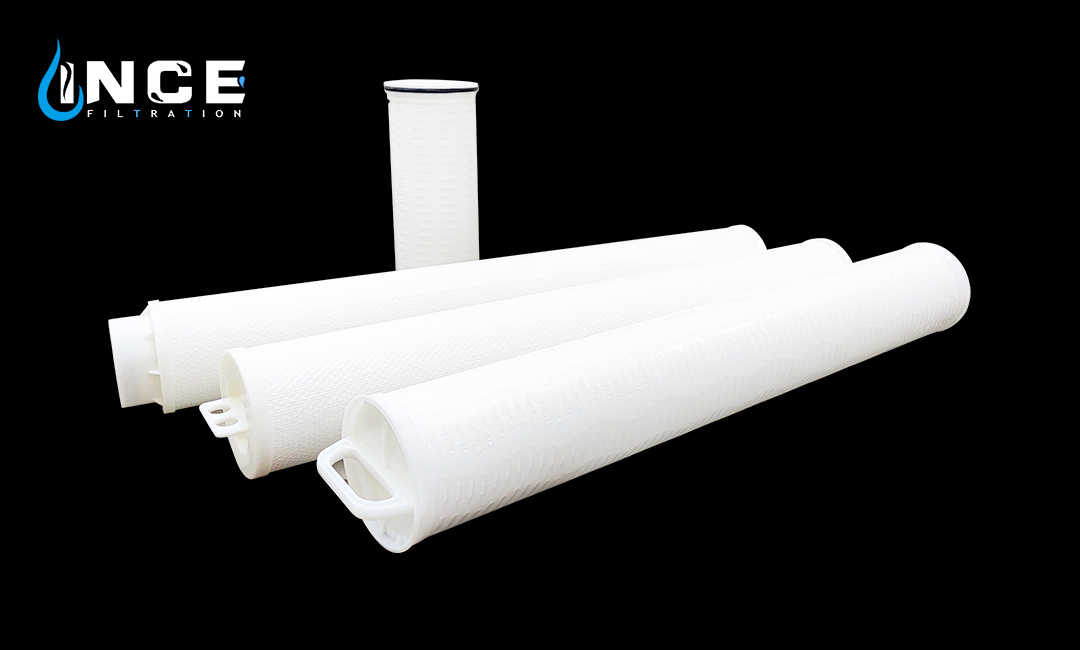

Filtration is a crucial process in many industries, from water treatment to pharmaceutical manufacturing. The quality of filtration directly impacts the efficiency and effectiveness of the entire process. One way to maximize filtration power is by using PP pleated cartridges. These cartridges are designed to provide superior filtration performance and offer a range of benefits that make them a popular choice for many applications.

PP pleated cartridges are made from polypropylene, a thermoplastic polymer known for its excellent chemical resistance and durability. This material is ideal for filtration applications because it can withstand a wide range of temperatures and pH levels without degrading. PP pleated cartridges are also resistant to bacteria and fungi, making them suitable for use in sterile environments.

One of the key benefits of using PP pleated cartridges is their high dirt-holding capacity. The pleated design of these cartridges provides a large surface area for filtration, allowing them to capture more particles and contaminants than traditional filter cartridges. This means that PP pleated cartridges can effectively remove impurities from liquids and gases, ensuring a clean and pure end product.

In addition to their high dirt-holding capacity, PP pleated cartridges offer excellent flow rates. The pleated design creates a uniform flow path for the liquid or gas being filtered, minimizing pressure drop and ensuring efficient filtration. This means that PP pleated cartridges can process large volumes of fluid quickly and effectively, making them ideal for high-flow applications.

Another advantage of PP pleated cartridges is their long service life. The durable polypropylene material is resistant to chemical degradation and mechanical wear, ensuring that these cartridges can withstand harsh operating conditions without losing their filtration efficiency. This means that PP pleated cartridges require less frequent replacement, reducing maintenance costs and downtime.

PP pleated cartridges are also easy to install and replace, thanks to their universal design and compatibility with standard filter housings. This makes them a convenient and cost-effective filtration solution for a wide range of applications. Whether you are filtering water, chemicals, or pharmaceuticals, PP pleated cartridges can provide reliable and consistent filtration performance.

In conclusion, PP pleated cartridges are an excellent choice for maximizing filtration power in various industries. Their high dirt-holding capacity, excellent flow rates, long service life, and ease of installation make them a versatile and cost-effective filtration solution. By choosing PP pleated cartridges for your filtration needs, you can ensure clean and pure end products while reducing maintenance costs and downtime.

How to Choose the Right PP Pleated Cartridges for Your Filtration System

When it comes to choosing the right filtration system for your industrial or commercial needs, PP pleated cartridges are a popular choice due to their high filtration efficiency and durability. These cartridges are made from polypropylene, a thermoplastic polymer known for its excellent chemical resistance and mechanical strength. PP pleated cartridges are designed to remove contaminants such as sediment, dirt, rust, and other particles from liquids, making them ideal for a wide range of applications including water treatment, food and beverage processing, pharmaceuticals, and more.

One of the key factors to consider when choosing PP pleated cartridges for your filtration system is the micron rating. The micron rating refers to the size of particles that the cartridge can effectively remove from the liquid. PP pleated cartridges are available in a range of micron ratings, typically ranging from 1 to 100 microns. The lower the micron rating, the smaller the particles that the cartridge can capture. For applications where fine filtration is required, such as in the pharmaceutical or electronics industry, a lower micron rating is recommended. On the other hand, for general-purpose filtration, a higher micron rating may be sufficient.

Another important consideration when selecting PP pleated cartridges is the length and diameter of the cartridge. PP pleated cartridges come in various lengths and diameters to fit different filtration systems. The length of the cartridge determines the surface area available for filtration, while the diameter affects the flow rate and capacity of the cartridge. It is important to choose a cartridge size that is compatible with your filtration system and meets the requirements of your specific application.

In addition to micron rating and size, the material construction of PP pleated cartridges is also an important factor to consider. PP pleated cartridges are available in different configurations, including single-layer and multi-layer designs. Single-layer cartridges are typically used for general-purpose filtration, while multi-layer cartridges offer enhanced filtration efficiency and dirt-holding capacity. The pleated design of the cartridge provides a larger filtration area, allowing for greater particle retention and longer service life.

When selecting PP pleated cartridges for your filtration system, it is important to consider the operating conditions and compatibility with the liquid being filtered. PP pleated cartridges are suitable for a wide range of liquids, including water, chemicals, oils, and solvents. However, it is important to ensure that the cartridge material is compatible with the liquid being filtered to prevent degradation or contamination. Additionally, consider the temperature and pressure requirements of your application to ensure that the cartridge can withstand the operating conditions.

In conclusion, PP pleated cartridges are an excellent choice for maximizing filtration power in your industrial or commercial filtration system. By considering factors such as micron rating, size, material construction, and compatibility with operating conditions, you can choose the right PP pleated cartridges to meet your specific filtration needs. With their high filtration efficiency, durability, and versatility, PP pleated cartridges are a reliable solution for removing contaminants and ensuring the quality of your liquid products.

Tips for Maintaining and Extending the Lifespan of PP Pleated Cartridges

PP pleated cartridges are a popular choice for filtration in various industries due to their high efficiency and durability. These cartridges are made from polypropylene, a thermoplastic polymer known for its excellent chemical resistance and mechanical strength. To maximize the filtration power of PP pleated cartridges and extend their lifespan, proper maintenance is essential.

One of the key tips for maintaining PP pleated cartridges is regular cleaning. Over time, dirt, debris, and contaminants can accumulate on the surface of the cartridges, reducing their effectiveness. To prevent clogging and ensure optimal filtration performance, it is important to clean the cartridges at regular intervals. This can be done by rinsing the cartridges with water or using a mild detergent to remove any buildup.

In addition to regular cleaning, it is also important to replace PP pleated cartridges when they reach the end of their lifespan. The lifespan of a cartridge will vary depending on factors such as the type of contaminants being filtered, the flow rate of the system, and the frequency of use. By monitoring the condition of the cartridges and replacing them as needed, you can ensure that your filtration system continues to operate efficiently.

Another tip for maximizing the filtration power of PP pleated cartridges is to use the correct size and type of cartridge for your specific application. Cartridges come in a variety of sizes and configurations, so it is important to choose the right one for your filtration needs. Using the wrong type of cartridge can result in poor filtration performance and reduced lifespan. Consult with a filtration expert to determine the best cartridge for your system.

Proper installation is also crucial for maintaining PP pleated cartridges. Cartridges should be installed according to the manufacturer’s instructions to ensure proper alignment and sealing. Improper installation can lead to leaks, bypassing of contaminants, and reduced filtration efficiency. If you are unsure about how to install the cartridges correctly, seek assistance from a professional.

Regular monitoring of the filtration system is another important aspect of maintaining PP pleated cartridges. By monitoring the pressure, flow rate, and overall performance of the system, you can identify any issues early on and take corrective action. This can help prevent damage to the cartridges and ensure that they continue to operate at peak efficiency.

In conclusion, PP pleated cartridges are a reliable and efficient filtration solution for a wide range of applications. By following these tips for maintaining and extending the lifespan of PP pleated cartridges, you can maximize their filtration power and ensure long-lasting performance. With proper maintenance, cleaning, replacement, and monitoring, you can keep your filtration system running smoothly and effectively.