Maximize Your Yield: The Impact of Bag Size on Rosin Extraction

Bag Size Selection: Finding the Optimal Size for Maximum Yield

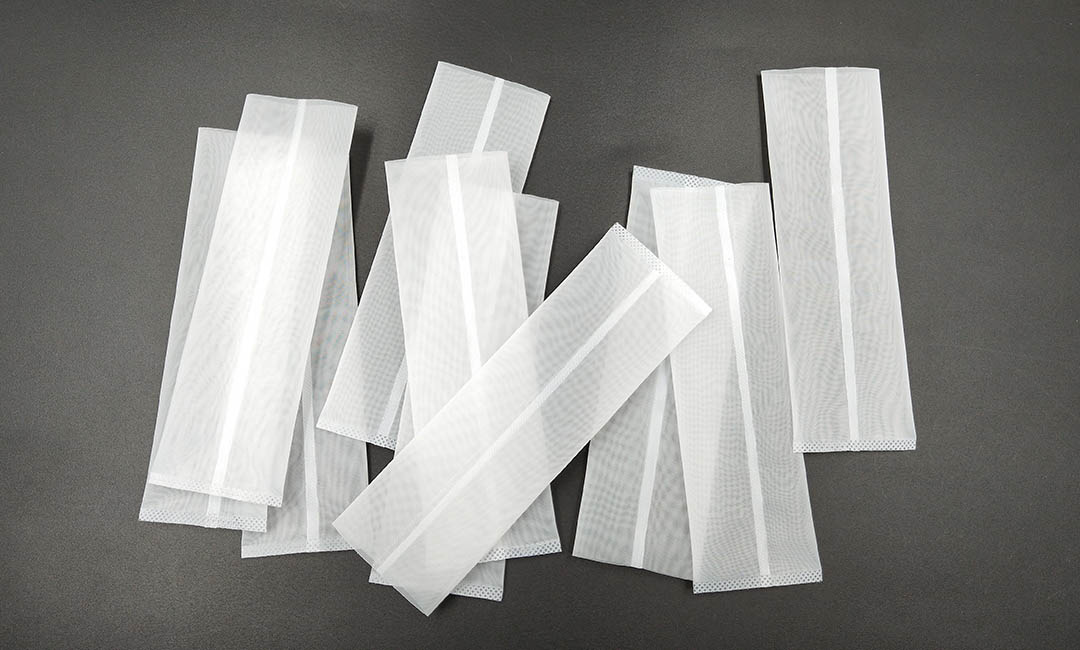

When it comes to maximizing yield in rosin extraction, the selection of bag size plays a crucial role that is often overlooked. The bag size directly influences the efficiency of the extraction process, affecting both the quantity and quality of the final product. To understand the impact of bag size on yield, it is essential to consider the relationship between the size of the material being processed and the dimensions of the extraction bag. A well-chosen bag size can facilitate optimal pressure distribution and material flow, ultimately leading to a more effective extraction.

In the realm of rosin extraction, bags are typically measured in microns, which denote the size of the mesh openings. Smaller micron sizes are designed to filter out finer particles, while larger sizes allow for more substantial material to pass through. Therefore, selecting the appropriate micron size is critical. For instance, using a bag with a micron size that is too small may result in clogging, which can hinder the flow of the rosin and reduce overall yield. Conversely, a bag that is too large may allow unwanted plant material to contaminate the final product, compromising its quality.

Moreover, the volume of the bag must also be taken into account. A bag that is too small may not accommodate the amount of material being processed, leading to overpacking. Overpacking can create uneven pressure distribution during extraction, which can negatively impact yield. On the other hand, a bag that is excessively large may lead to inefficient extraction, as the material may not be adequately compressed to release the rosin effectively. Therefore, finding the optimal bag size is a balancing act that requires careful consideration of both micron size and volume.

In addition to the physical dimensions of the bag, the type of material being extracted also influences the choice of bag size. Different strains of cannabis or other botanicals have varying densities and moisture contents, which can affect how they behave during extraction. For denser materials, a smaller bag size may be more effective, as it can help to contain the material and ensure that pressure is applied uniformly. Conversely, lighter or fluffier materials may benefit from a larger bag size, allowing for better airflow and extraction efficiency.

Furthermore, the extraction method employed can also dictate the ideal bag size. For example, hydraulic presses may require different bag sizes compared to pneumatic presses due to the differences in pressure application. Understanding the specific requirements of the extraction method being used is essential for optimizing bag size selection. Additionally, experimenting with various bag sizes can provide valuable insights into the unique characteristics of the material being processed, allowing for fine-tuning of the extraction process.

Ultimately, the selection of bag size is a critical factor in maximizing yield during rosin extraction. By carefully considering micron size, volume, material characteristics, and extraction methods, one can identify the optimal bag size that enhances both yield and quality. This thoughtful approach not only improves the efficiency of the extraction process but also contributes to the overall success of the operation. As the industry continues to evolve, staying informed about best practices in bag size selection will remain essential for those seeking to achieve the highest possible yields in rosin extraction.

The Science Behind Bag Size: How It Affects Rosin Quality

The process of rosin extraction has gained significant popularity in recent years, particularly among cannabis enthusiasts and producers seeking a solventless method to obtain high-quality concentrates. One of the critical factors influencing the quality and yield of rosin is the size of the extraction bag used during the process. Understanding the science behind bag size can provide valuable insights into how it affects the overall quality of the final product.

To begin with, the extraction bag serves as a filter that retains plant material while allowing the desired resinous compounds to pass through. The size of the bag, typically measured in microns, determines the size of the particles that can be filtered out. Smaller bags, often ranging from 25 to 90 microns, are designed to capture finer particles, which can lead to a cleaner and more refined product. Conversely, larger bags, such as those measuring 160 microns or more, may allow more plant material to pass through, potentially resulting in a product that is less pure and contains undesirable contaminants.

Moreover, the choice of bag size can significantly impact the yield of rosin extraction. When using smaller bags, the extraction process may yield a lower quantity of rosin due to the more stringent filtration. However, this trade-off often results in a higher quality product, as the smaller bags effectively filter out unwanted plant material and chlorophyll, which can impart undesirable flavors and colors. On the other hand, larger bags may produce a higher yield, but the quality of the rosin may suffer as a result of the inclusion of these unwanted compounds.

In addition to the size of the bag, the pressure applied during extraction also plays a crucial role in determining the quality of the final product. When using smaller bags, it is essential to apply the right amount of pressure to ensure that the resin is efficiently extracted without compromising the integrity of the bag. Excessive pressure can lead to the rupture of the bag, allowing unwanted plant material to contaminate the rosin. Therefore, finding the optimal balance between bag size and pressure is vital for achieving the best possible results.

Furthermore, the moisture content of the starting material can also influence the effectiveness of different bag sizes. Drier material tends to yield better results when using smaller bags, as the resin can be more easily separated from the plant matter. Conversely, if the material is too moist, larger bags may be more effective in facilitating the extraction process, as they allow for better drainage and prevent clogging. This interplay between bag size, moisture content, and extraction pressure underscores the importance of considering multiple factors when aiming to maximize yield and quality.

In conclusion, the science behind bag size in rosin extraction is multifaceted, with significant implications for both yield and quality. Smaller bags can produce a more refined product by filtering out unwanted particles, while larger bags may yield more rosin but at the potential cost of purity. Additionally, the interplay between bag size, pressure, and moisture content further complicates the extraction process. By understanding these dynamics, producers can make informed decisions that ultimately enhance the quality of their rosin, ensuring that they achieve the best possible results in their extraction endeavors.

Common Mistakes: Choosing the Wrong Bag Size for Extraction

When it comes to rosin extraction, the choice of bag size is a critical factor that can significantly influence the yield and quality of the final product. Many individuals, whether they are novices or seasoned extractors, often overlook the importance of selecting the appropriate bag size, leading to common mistakes that can hinder their extraction process. Understanding the implications of bag size is essential for maximizing yield and ensuring a successful extraction.

One prevalent mistake is using a bag that is either too large or too small for the amount of material being processed. A bag that is too large can lead to inefficient extraction, as the material may not be evenly distributed, resulting in uneven pressure during the extraction process. This uneven pressure can cause some areas of the material to be over-extracted while others remain under-extracted, ultimately compromising the quality of the rosin. Conversely, using a bag that is too small can lead to overpacking, which restricts the flow of the extracted oils and can create excessive pressure. This not only risks damaging the bag but can also result in a lower yield, as the material may not be able to release its full potential.

Another common error is failing to consider the micron size of the bag in relation to the type of material being used. Different materials, such as flower, hash, or kief, have varying particle sizes, and selecting a bag with an inappropriate micron size can lead to suboptimal results. For instance, using a bag with too large a micron size for fine material can allow unwanted plant matter to pass through, resulting in a lower quality product. On the other hand, using a bag with too small a micron size for coarser material can lead to clogging, which can impede the extraction process and reduce overall yield. Therefore, it is crucial to match the micron size of the bag to the specific characteristics of the material being processed.

Moreover, many extractors neglect to account for the volume of material they intend to process. It is essential to have a clear understanding of how much material will fit comfortably within the bag without causing overpacking. Overpacking not only increases the risk of damaging the bag but also limits the efficiency of the extraction process. When the material is tightly packed, the heat and pressure may not be able to penetrate evenly, leading to inconsistent results. Therefore, it is advisable to leave some space within the bag to allow for proper expansion and flow during extraction.

In addition to these considerations, it is also important to recognize that the extraction method being employed can influence the choice of bag size. Different methods, such as hydraulic presses or pneumatic systems, may require specific bag sizes to optimize performance. Understanding the compatibility between the extraction method and bag size can further enhance the efficiency of the process.

In conclusion, selecting the right bag size for rosin extraction is a fundamental aspect that can greatly impact yield and quality. By avoiding common mistakes such as choosing bags that are too large or small, failing to consider micron size, neglecting material volume, and overlooking the extraction method, extractors can significantly improve their results. Ultimately, a thoughtful approach to bag size selection will not only maximize yield but also enhance the overall quality of the rosin produced, leading to a more satisfying extraction experience.

Comparing Bag Sizes: Yield Differences in Rosin Extraction Techniques

In the realm of rosin extraction, the choice of bag size plays a pivotal role in determining the yield and quality of the final product. As enthusiasts and professionals alike seek to maximize their output, understanding the nuances of bag sizes becomes essential. The extraction process, which involves applying heat and pressure to cannabis material, is influenced significantly by the dimensions of the bags used to contain the plant matter. Consequently, a careful comparison of bag sizes reveals critical insights into yield differences that can impact both efficiency and profitability.

When considering bag sizes, it is important to recognize that smaller bags tend to concentrate the material more tightly. This can lead to a more efficient extraction process, as the heat and pressure are applied uniformly across a smaller surface area. As a result, smaller bags often yield a higher percentage of rosin relative to the amount of starting material. However, this does not come without its drawbacks. The increased density can sometimes lead to a more challenging extraction process, as the material may become overly compacted, hindering the flow of oils and resins. Therefore, while smaller bags may promise higher yields, they also require careful monitoring to ensure optimal extraction conditions.

On the other hand, larger bags offer a different set of advantages and challenges. With more space to accommodate the plant material, larger bags can facilitate a more even distribution of heat and pressure. This can lead to a smoother extraction process, allowing for a more consistent quality of rosin. However, the trade-off is often a lower yield percentage. The larger volume can dilute the concentration of the essential oils and resins, resulting in a less potent final product. Thus, while larger bags may simplify the extraction process, they may not always be the best choice for those seeking maximum yield.

Moreover, the type of material used in the bags can also influence the extraction outcome. Bags made from different micron sizes can affect the filtration process, impacting both yield and quality. For instance, bags with a finer micron size can trap more plant material, potentially leading to a higher yield. However, this can also result in a more challenging cleanup process and may introduce unwanted plant matter into the final product. Conversely, bags with a coarser micron size may allow for a cleaner extraction but could sacrifice some yield in the process. Therefore, the interplay between bag size and micron size is crucial for achieving the desired balance between yield and quality.

In addition to these technical considerations, the choice of bag size can also be influenced by the specific goals of the extractor. For those focused on maximizing yield for commercial purposes, smaller bags may be the preferred option, despite the potential challenges. Conversely, hobbyists or those prioritizing quality over quantity may find larger bags more suitable for their needs. Ultimately, the decision regarding bag size should be informed by a comprehensive understanding of the extraction process, as well as the desired outcomes.

In conclusion, the impact of bag size on rosin extraction is multifaceted, with significant implications for yield and quality. By carefully comparing the advantages and disadvantages of different bag sizes, extractors can make informed decisions that align with their specific goals. Whether opting for smaller bags to maximize yield or larger bags for ease of extraction, understanding these dynamics is essential for anyone looking to optimize their rosin extraction process.