Maximizing Performance with Ultipleat High Flow Filters

Benefits of Using Ultipleat High Flow Filters for Industrial Applications

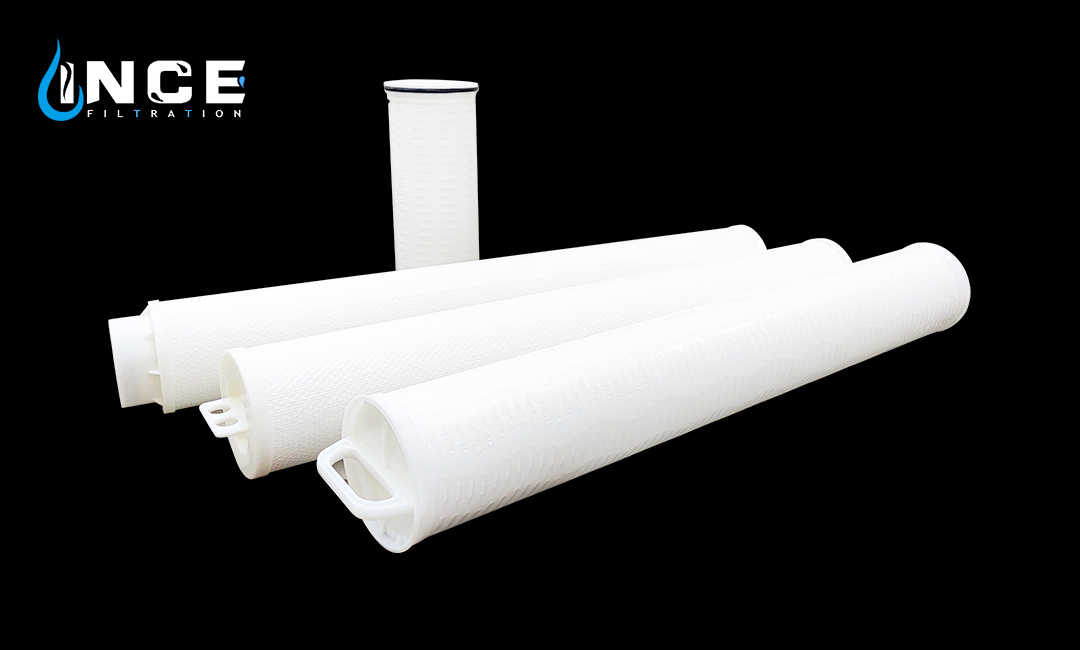

In the realm of industrial applications, the efficiency and reliability of filtration systems play a crucial role in maintaining optimal operational performance. Among the various filtration solutions available, Ultipleat High Flow Filters have emerged as a leading choice for many industries due to their numerous benefits. These filters are designed to enhance the filtration process while minimizing downtime and maintenance costs, making them an invaluable asset in various industrial settings.

One of the primary advantages of Ultipleat High Flow Filters is their ability to handle high flow rates without compromising filtration efficiency. This characteristic is particularly beneficial in applications where large volumes of fluid need to be processed quickly, such as in chemical manufacturing, oil and gas production, and water treatment facilities. By accommodating higher flow rates, these filters help to streamline operations, allowing for increased productivity and reduced energy consumption. Consequently, industries can achieve significant cost savings while maintaining the quality of their output.

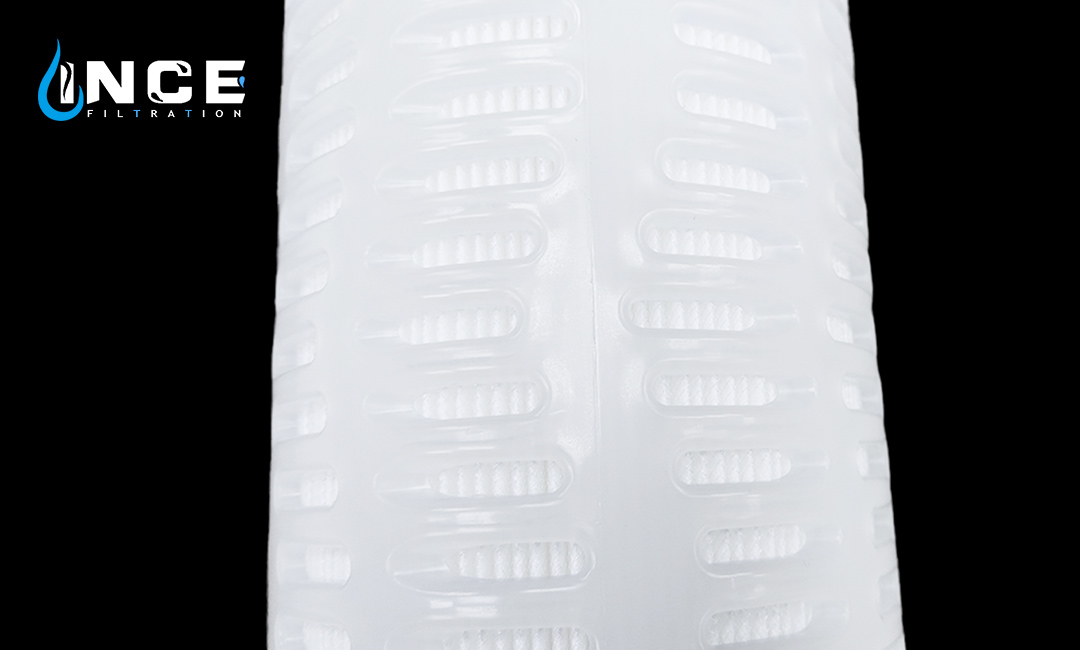

Moreover, the design of Ultipleat High Flow Filters incorporates advanced pleating technology, which maximizes the surface area available for filtration. This innovative design not only enhances the filter’s capacity to capture contaminants but also extends its service life. As a result, users experience longer intervals between filter replacements, which translates to lower maintenance costs and reduced waste. The extended service life of these filters also contributes to a more sustainable approach to industrial operations, as fewer filters need to be disposed of over time.

In addition to their efficiency and longevity, Ultipleat High Flow Filters are engineered to provide superior dirt-holding capacity. This feature is essential in environments where particulate contamination is prevalent, as it ensures that the filters can effectively trap and retain a significant amount of dirt and debris. By maintaining a high level of filtration performance, these filters help to protect downstream equipment from damage and wear, thereby reducing the risk of costly repairs and unplanned downtime. Consequently, industries can operate with greater confidence, knowing that their filtration systems are working effectively to safeguard their processes.

Furthermore, the versatility of Ultipleat High Flow Filters makes them suitable for a wide range of applications across various sectors. Whether used in food and beverage processing, pharmaceuticals, or industrial water treatment, these filters can be tailored to meet specific operational requirements. This adaptability is particularly advantageous for companies that operate in multiple industries or those that require customized filtration solutions to address unique challenges. By providing a flexible filtration option, Ultipleat High Flow Filters enable businesses to optimize their processes and enhance overall performance.

Another noteworthy benefit of Ultipleat High Flow Filters is their ease of installation and maintenance. Designed with user convenience in mind, these filters can be quickly integrated into existing systems, minimizing disruption to operations. Additionally, their straightforward maintenance requirements allow personnel to perform routine checks and replacements with minimal training, further enhancing operational efficiency. This ease of use is particularly valuable in fast-paced industrial environments where time is of the essence.

In conclusion, the benefits of using Ultipleat High Flow Filters for industrial applications are manifold. From their ability to handle high flow rates and extended service life to their superior dirt-holding capacity and versatility, these filters provide a comprehensive solution for enhancing filtration performance. By investing in Ultipleat High Flow Filters, industries can not only improve their operational efficiency but also achieve significant cost savings and contribute to more sustainable practices. As the demand for reliable and efficient filtration solutions continues to grow, Ultipleat High Flow Filters stand out as a premier choice for businesses seeking to maximize their performance.

How Ultipleat High Flow Filters Improve Efficiency and Productivity

In today’s fast-paced industrial landscape, the demand for efficiency and productivity is paramount. One of the key components that can significantly enhance operational performance is the filtration system employed in various processes. Ultipleat High Flow Filters have emerged as a leading solution in this regard, offering a range of benefits that contribute to improved efficiency and productivity across multiple sectors. By understanding how these filters function and their advantages, organizations can make informed decisions that lead to enhanced operational outcomes.

Ultipleat High Flow Filters are designed with a unique pleated structure that maximizes the surface area available for filtration. This innovative design allows for a higher flow rate while maintaining effective particle removal capabilities. As a result, these filters can handle larger volumes of fluid with less resistance, which is crucial in applications where maintaining flow rates is essential. The ability to process more fluid without compromising filtration quality means that systems can operate more smoothly and efficiently, reducing the likelihood of downtime caused by clogged filters.

Moreover, the efficiency of Ultipleat High Flow Filters translates directly into productivity gains. When filtration systems operate effectively, the overall process becomes more streamlined. For instance, in manufacturing environments, clean fluids are essential for machinery operation. By utilizing Ultipleat filters, companies can ensure that their equipment runs optimally, minimizing the risk of breakdowns and maintenance interruptions. This reliability not only enhances productivity but also extends the lifespan of machinery, leading to further cost savings over time.

In addition to their structural advantages, Ultipleat High Flow Filters are engineered to be easy to install and replace. This user-friendly design reduces the time and labor associated with filter maintenance, allowing personnel to focus on more critical tasks. The quick-change feature of these filters means that organizations can minimize downtime during maintenance activities, thereby maximizing operational efficiency. Furthermore, the reduced frequency of filter changes due to the high dirt-holding capacity of Ultipleat filters means that companies can allocate resources more effectively, enhancing overall productivity.

Another significant aspect of Ultipleat High Flow Filters is their versatility. These filters can be utilized in a wide range of applications, from water treatment to food and beverage processing, and even in pharmaceutical manufacturing. This adaptability allows organizations to standardize their filtration solutions across different processes, simplifying inventory management and reducing training requirements for staff. By streamlining operations in this manner, companies can achieve greater consistency in their processes, which is a critical factor in maintaining high productivity levels.

Furthermore, the environmental benefits of using Ultipleat High Flow Filters cannot be overlooked. By improving the efficiency of filtration systems, these filters contribute to reduced energy consumption and lower waste generation. This not only aligns with sustainability goals but also enhances the overall corporate image of organizations committed to responsible practices. As industries increasingly focus on sustainability, the adoption of efficient filtration solutions like Ultipleat filters can provide a competitive edge.

In conclusion, Ultipleat High Flow Filters represent a significant advancement in filtration technology, offering numerous benefits that enhance efficiency and productivity. Their unique design, ease of maintenance, versatility, and environmental advantages make them an ideal choice for organizations seeking to optimize their operations. By investing in these high-performance filters, companies can ensure that they remain competitive in an ever-evolving industrial landscape, ultimately leading to improved outcomes and sustained growth.

Case Studies Demonstrating Performance Gains with Ultipleat High Flow Filters

In the world of industrial filtration, maximizing performance is crucial for ensuring efficiency and cost-effectiveness. One way to achieve this is by using Ultipleat High Flow Filters, which are designed to provide superior filtration performance in a wide range of applications. These filters offer a number of advantages over traditional filtration methods, including higher flow rates, lower pressure drops, and longer service life.

One case study that demonstrates the performance gains achieved with Ultipleat High Flow Filters is in the oil and gas industry. In this industry, filtration is essential for removing contaminants from the production process and ensuring the quality of the final product. By using Ultipleat High Flow Filters, companies have been able to achieve higher flow rates and lower pressure drops, resulting in increased productivity and cost savings.

Another industry where Ultipleat High Flow Filters have proven to be highly effective is in the pharmaceutical industry. In this highly regulated industry, maintaining the purity of products is of utmost importance. By using Ultipleat High Flow Filters, pharmaceutical companies have been able to achieve the level of filtration required to meet regulatory standards, while also reducing operating costs and downtime.

One of the key advantages of Ultipleat High Flow Filters is their long service life. Traditional filters often need to be replaced frequently, leading to increased maintenance costs and downtime. Ultipleat High Flow Filters, on the other hand, have been shown to last significantly longer, reducing the frequency of filter changes and increasing overall efficiency.

In addition to their superior performance, Ultipleat High Flow Filters are also easy to install and maintain. This makes them an ideal choice for companies looking to improve their filtration processes without incurring additional costs or downtime. By choosing Ultipleat High Flow Filters, companies can achieve the level of filtration required for their specific application, while also maximizing performance and efficiency.

Overall, Ultipleat High Flow Filters have been shown to provide significant performance gains in a wide range of industries. From oil and gas to pharmaceuticals, these filters offer a cost-effective solution for improving filtration processes and achieving regulatory compliance. With their high flow rates, low pressure drops, and long service life, Ultipleat High Flow Filters are a reliable choice for companies looking to maximize performance and efficiency in their filtration systems.

Tips for Proper Maintenance and Care of Ultipleat High Flow Filters

Maximizing the performance of Ultipleat High Flow Filters requires a commitment to proper maintenance and care. These filters are designed to provide superior filtration efficiency and extended service life, but their effectiveness can be compromised if not maintained correctly. To ensure optimal performance, it is essential to follow a systematic approach to their upkeep.

First and foremost, regular inspection is crucial. By routinely checking the filters for signs of wear, damage, or clogging, operators can identify potential issues before they escalate. This proactive measure not only extends the life of the filters but also maintains the quality of the fluid being filtered. During inspections, it is advisable to examine the filter media for any visible debris or discoloration, as these can indicate that the filter is nearing its capacity. Additionally, monitoring the pressure drop across the filter can provide valuable insights into its condition. A significant increase in pressure drop may signal that the filter is becoming clogged and requires replacement.

In conjunction with regular inspections, adhering to a defined replacement schedule is vital. While Ultipleat High Flow Filters are engineered for longevity, their lifespan can vary based on the specific application and operating conditions. Therefore, it is important to consult the manufacturer’s guidelines and consider factors such as flow rates, fluid characteristics, and environmental conditions when determining the appropriate replacement frequency. By establishing a routine replacement schedule, operators can prevent unexpected downtime and ensure that the filtration system operates at peak efficiency.

Moreover, proper handling during installation and replacement is essential to maintain the integrity of the filters. Care should be taken to avoid damaging the filter media or seals during these processes. Utilizing appropriate tools and techniques can help prevent unnecessary stress on the filters, thereby enhancing their performance and longevity. Additionally, ensuring that the filter is installed in the correct orientation and that all connections are secure will further contribute to optimal operation.

Another important aspect of filter maintenance is cleanliness. Keeping the surrounding area free from contaminants can significantly reduce the risk of introducing foreign particles into the filtration system. It is advisable to clean the installation area before replacing filters and to use clean tools to minimize the potential for contamination. Furthermore, operators should be cautious when handling used filters, as they may contain trapped contaminants. Proper disposal methods should be followed to ensure that these materials do not pose a risk to the environment or personnel.

In addition to these practices, it is beneficial to maintain accurate records of filter performance and maintenance activities. Documenting pressure readings, replacement dates, and any observed issues can provide valuable data for future reference. This information can help identify trends and inform decisions regarding filter selection and maintenance strategies, ultimately leading to improved system performance.

In conclusion, maximizing the performance of Ultipleat High Flow Filters hinges on diligent maintenance and care. By implementing regular inspections, adhering to a replacement schedule, ensuring proper handling, maintaining cleanliness, and keeping detailed records, operators can significantly enhance the efficiency and longevity of their filtration systems. These practices not only contribute to optimal performance but also support the overall reliability of the processes that depend on effective filtration. Through a commitment to these maintenance strategies, users can fully leverage the capabilities of Ultipleat High Flow Filters, ensuring that they continue to deliver exceptional results in various applications.