Melt Blown Polypropylene Filter Cartridge: A Comprehensive Solution for Effective Filtration

The melt-blown polypropylene filter cartridge is an essential component in a wide range of industries, offering exceptional filtration capabilities. These cartridges have been specifically designed to handle contaminants and particulates in both liquid and gas filtration systems, making them ideal for use in water treatment plants, industrial processes, food and beverage industries, and healthcare sectors. With the rise of stricter environmental and safety regulations, businesses must rely on high-quality filtration solutions to maintain clean, safe, and efficient operations.

What is a Melt-Blown Polypropylene Filter Cartridge?

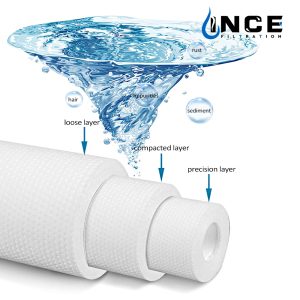

A melt-blown polypropylene filter cartridge is made by extruding polypropylene resin through a series of fine nozzles. The molten polymer is stretched and deposited onto a rotating cylinder or belt, forming a random pattern of fibers. These fibers are then bonded together without the need for adhesives or binders, creating a continuous structure. The result is a highly porous filter medium with an excellent ability to trap contaminants, making it particularly effective in removing particulate matter from liquids or gases.

The melt-blown process creates filters with graded pore structures, offering a depth filtration design. This means that contaminants are captured not only on the surface but throughout the depth of the filter, increasing its holding capacity and extending the filter’s lifespan.

Key Features of Melt-Blown Polypropylene Filter Cartridges

- High Filtration Efficiency: Melt-blown polypropylene filters are capable of removing up to 99% of contaminants, making them suitable for both general-purpose filtration and high-efficiency applications. These filters can capture a wide range of particle sizes, including sediments, sand, rust, and other suspended solids.

- Chemical Resistance: One of the key advantages of using polypropylene is its high chemical resistance. It can withstand exposure to acids, alkalis, and various solvents, making it an excellent choice for industrial processes that involve aggressive chemicals.

- Depth Filtration: The depth filtration design allows for the retention of contaminants throughout the entire depth of the filter cartridge, resulting in higher dirt-holding capacity and longer service life compared to surface filtration filters.

- Wide Range of Micron Ratings: Melt-blown polypropylene cartridges are available in various micron ratings, ranging from 1 micron to 100 microns. This allows users to select the appropriate filter for their specific application, ensuring optimal performance and efficiency.

- Cost-Effective: The melt-blown manufacturing process is cost-efficient, allowing for the production of high-quality filters at a lower cost. This makes these cartridges an affordable solution for businesses that require reliable filtration systems without compromising performance.

Applications of Melt-Blown Polypropylene Filter Cartridges

Due to their versatility and exceptional filtration performance, melt-blown polypropylene filter cartridges are used in a wide range of industries. Some of the key applications include:

- Water Filtration: These cartridges are commonly used in residential, commercial, and industrial water filtration systems. They effectively remove sediments, rust, and other particulate matter from water, improving its quality and protecting downstream equipment from damage.

- Food and Beverage Industry: In the food and beverage industry, maintaining a clean and safe production environment is critical. Melt-blown polypropylene filters are used to remove contaminants from process water, beverages, and food products, ensuring that they meet strict safety and quality standards.

- Pharmaceuticals: In the pharmaceutical industry, high-purity water is essential for the production of medicines and other healthcare products. Melt-blown polypropylene cartridges are used in pharmaceutical-grade water filtration systems to remove particulates and contaminants, ensuring the purity of the water used in production.

- Oil and Gas: In the oil and gas sector, these filters are used to remove contaminants from hydraulic fluids, lubricants, and other process fluids. The ability to withstand harsh chemicals and high temperatures makes melt-blown polypropylene filters an excellent choice for this demanding industry.

- Industrial Process Filtration: Melt-blown polypropylene filter cartridges are widely used in various industrial applications, including chemical manufacturing, automotive production, and metalworking. They help protect equipment and ensure the quality of final products by removing contaminants from process fluids.

- HVAC Systems: Melt-blown polypropylene cartridges are also used in HVAC systems to remove dust, pollen, and other airborne particles from the air. This improves air quality and helps maintain a clean and healthy indoor environment.

Why Choose Melt-Blown Polypropylene Filter Cartridges?

Selecting the right filtration system for your business is crucial to ensuring optimal performance and cost-efficiency. Here are several reasons why melt-blown polypropylene filter cartridges should be your top choice:

- Reliability: Melt-blown polypropylene filters offer consistent performance and are highly reliable. Their depth filtration design ensures that contaminants are trapped throughout the entire filter, providing long-lasting and effective filtration.

- Versatility: These cartridges are available in a wide range of sizes, micron ratings, and configurations, making them suitable for a variety of applications. Whether you need to filter water, chemicals, or gases, there is a melt-blown polypropylene filter cartridge that can meet your needs.

- Durability: Polypropylene is a durable material that can withstand harsh environmental conditions and chemical exposure. This durability ensures that the filters maintain their structural integrity and filtration efficiency over time.

- Environmentally Friendly: Melt-blown polypropylene cartridges are made from a thermoplastic polymer that can be recycled, reducing environmental impact. Additionally, their long service life reduces the need for frequent replacements, resulting in less waste.

- Compliance with Industry Standards: Melt-blown polypropylene filter cartridges are manufactured to meet industry standards and regulations. Whether you are in the food and beverage industry, pharmaceuticals, or water treatment, these filters comply with stringent quality and safety requirements.

How to Choose the Right Melt-Blown Polypropylene Filter Cartridge for Your Application

When selecting a melt-blown polypropylene filter cartridge for your application, it is important to consider the following factors:

- Micron Rating: The micron rating of a filter determines the size of the particles it can capture. Lower micron ratings (e.g., 1 micron) are suitable for fine filtration, while higher ratings (e.g., 50 microns) are better for coarse filtration. Ensure that you choose a filter with the appropriate micron rating for your specific application.

- Flow Rate: The flow rate of a filter cartridge refers to the amount of fluid that can pass through the filter per unit of time. Consider the required flow rate for your system and choose a filter that can accommodate it without compromising filtration efficiency.

- Operating Temperature and Pressure: Melt-blown polypropylene cartridges are designed to operate within a specific temperature and pressure range. Make sure to select a filter that can withstand the operating conditions of your system.

- Chemical Compatibility: Polypropylene is compatible with many chemicals, but it is important to ensure that the filter will not degrade when exposed to certain solvents or chemicals in your process. Always check the chemical compatibility of the filter before use.

Conclusion

The melt-blown polypropylene filter cartridge is a highly effective, versatile, and cost-efficient filtration solution for various industries. Whether you need to filter water, air, chemicals, or industrial fluids, these filters provide reliable and long-lasting performance. With their high filtration efficiency, chemical resistance, and depth filtration capabilities, melt-blown polypropylene cartridges are the go-to choice for businesses seeking to improve their filtration systems and ensure the quality and safety of their products.

Investing in melt-blown polypropylene filter cartridges ensures that you have a reliable and cost-effective filtration solution that meets the demands of your industry, helping you maintain operational efficiency while protecting the environment and ensuring compliance with industry standards.

Melt Blown Filter Cartridge

PP Filter Cartridge: The Ideal Filtration Solution for Your Industry

Hot sell Melt-Blown Filter Cartridge

Acid and alkali resistant melt blown cartrridge for Industrial Filtration

Customized acid and alkali resistant PP melt-blown filter element for water filtration

PP melt blown filter cartridge 10″ 20″ 30″ 40″

Discover the Power of PP Melt Blown Filters: A Comprehensive Guide

Melt blown filter element