External transmission and internal density, good pollution interception effect, and long service life.

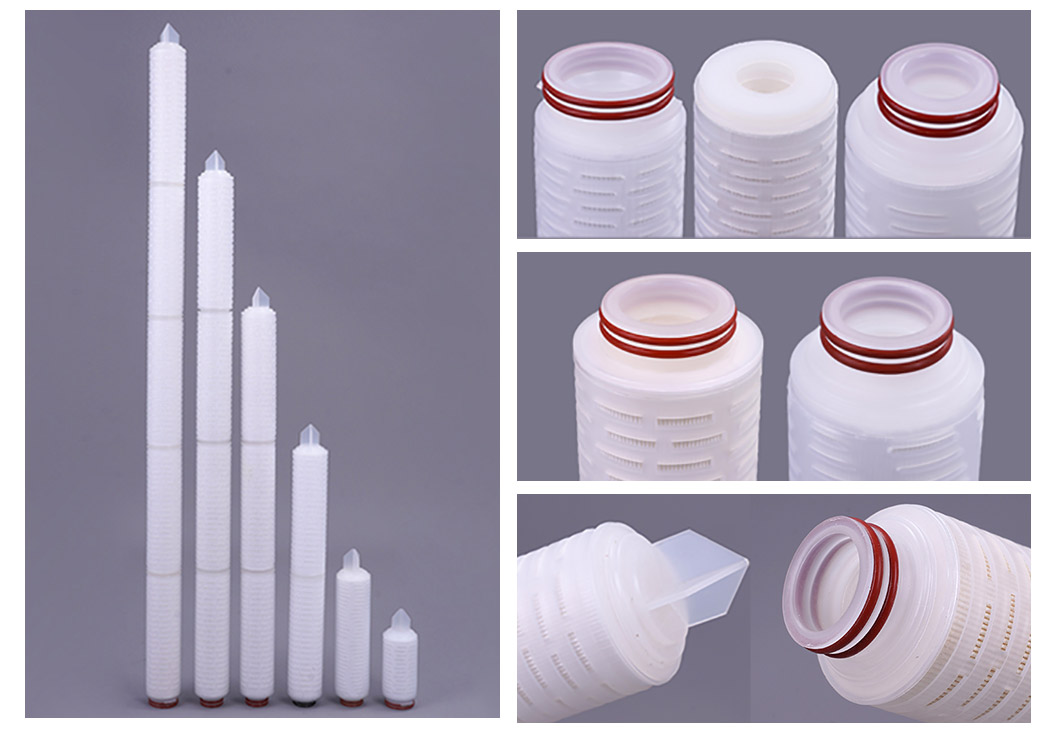

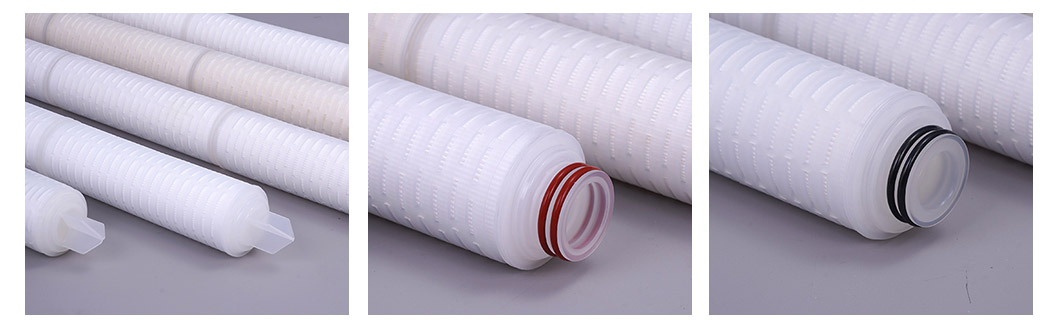

The nylon membrane filter cartridge takes the nylon microfiltration membrane as filter material. We have 0.2 μm, 0.45 μm, 0.65 μm and 1.0 μm pore sizes for you to choose from. Thermal bond technology is adopted, with no adhesives and no foreign matter falling off. Every filter cartridge must pass an integrity test to ensure the stability of the product’s performance.

|

Product name:

|

Nylon pleated filter cartridge

|

|||

|

Filter rating:

|

0.1, 0.22, 0.45, 1, 5 um

|

|||

|

Filter media:

|

Nylon microfiltration membrane

|

|||

|

Support/drainage:

|

PP

|

|||

|

Cage/core/end cap:

|

PP

|

|||

|

Seal method:

|

Thermal bond

|

|||

|

Effective filter area:

|

≥0.60m21 10″

|

|||

|

Filter cartridge diameter:

|

69.0 mm

|

|||

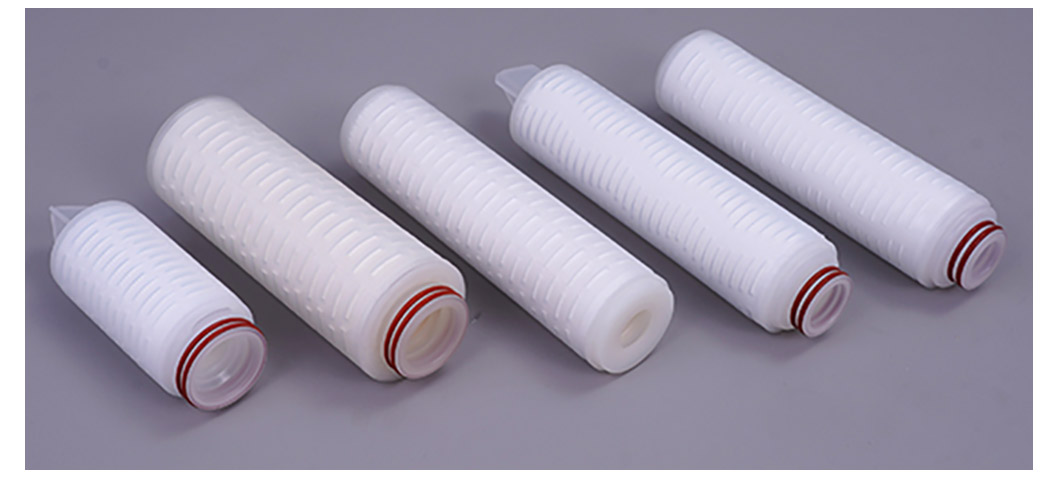

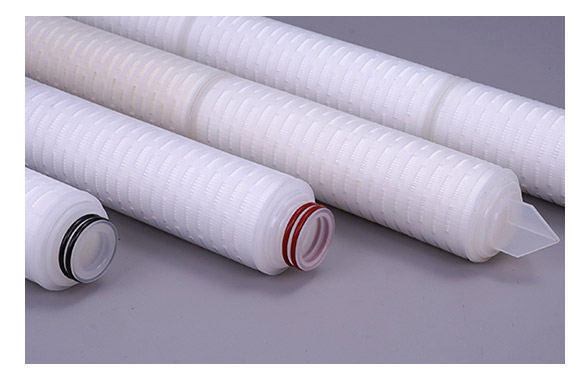

External transmission and internal density, good pollution interception effect, and long service life.

All interfaces use ultrasonic welding. Customized composite membrane materials are specially added. The interception efficiency can reach 98%.

Various types of non-standard filter elements can be customized according to the different needs of customers.