Pall Ultipleat High Flow: Advanced Filtration for Demanding Systems

Benefits of Pall Ultipleat High Flow Filters

Pall Ultipleat High Flow filters are a cutting-edge solution for demanding filtration systems. These filters offer a range of benefits that make them a top choice for industries that require high-performance filtration. From improved efficiency to cost savings, Pall Ultipleat High Flow filters deliver exceptional results that meet the needs of even the most challenging applications.

One of the key benefits of Pall Ultipleat High Flow filters is their superior filtration efficiency. These filters are designed to remove contaminants with high efficiency, ensuring that the filtered fluid meets the required purity standards. This level of filtration efficiency is essential for industries such as pharmaceuticals, food and beverage, and electronics, where even small contaminants can have a significant impact on product quality.

In addition to their high filtration efficiency, Pall Ultipleat High Flow filters also offer a longer service life compared to traditional filters. This extended service life is due to the unique design of these filters, which allows for a larger surface area and higher dirt-holding capacity. As a result, Pall Ultipleat High Flow filters require less frequent replacement, reducing downtime and maintenance costs for the end user.

Another benefit of Pall Ultipleat High Flow filters is their compatibility with a wide range of fluids and operating conditions. These filters are designed to handle high flow rates and pressures, making them suitable for a variety of applications. Whether filtering water, chemicals, or oils, Pall Ultipleat High Flow filters can deliver consistent performance and reliable results.

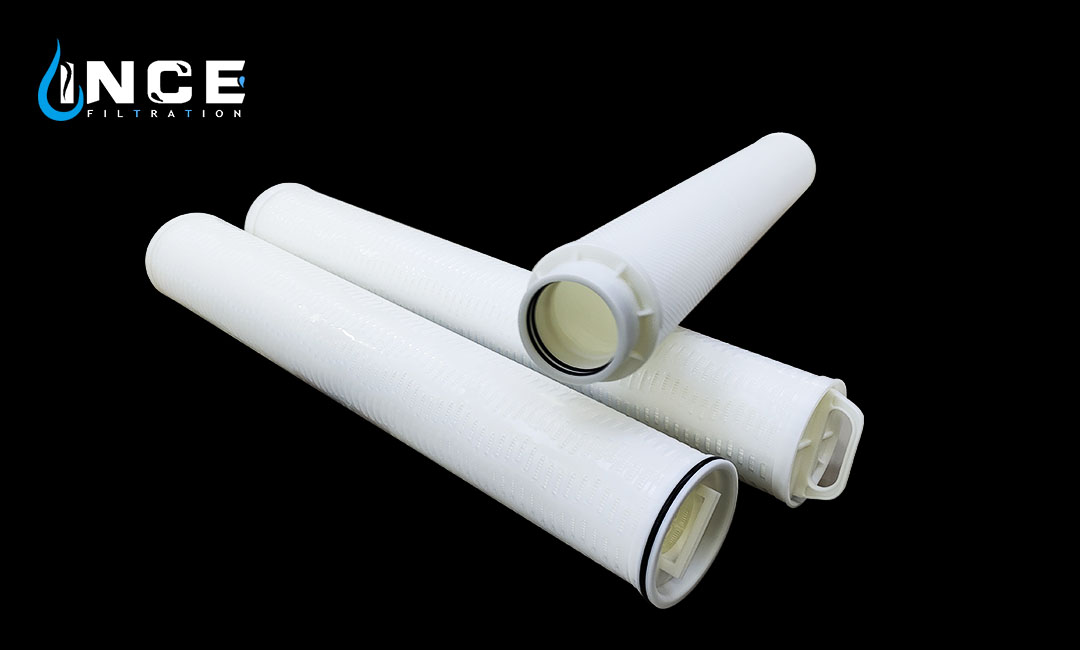

Furthermore, Pall Ultipleat High Flow filters are easy to install and maintain, thanks to their user-friendly design. These filters are available in a range of sizes and configurations to suit different system requirements, and can be easily integrated into existing filtration systems. Additionally, Pall Ultipleat High Flow filters are designed for quick and easy replacement, minimizing downtime and ensuring continuous operation.

Cost savings are another significant benefit of Pall Ultipleat High Flow filters. By offering superior filtration efficiency, longer service life, and easy maintenance, these filters help reduce overall operating costs for the end user. With fewer filter replacements and reduced downtime, Pall Ultipleat High Flow filters offer a cost-effective solution for demanding filtration systems.

In conclusion, Pall Ultipleat High Flow filters are an advanced filtration solution that offers a range of benefits for demanding systems. From superior filtration efficiency to longer service life and cost savings, these filters deliver exceptional performance that meets the needs of a variety of industries. With their compatibility with different fluids and operating conditions, user-friendly design, and cost-effective operation, Pall Ultipleat High Flow filters are a top choice for industries that require high-performance filtration.

Applications of Pall Ultipleat High Flow Filters

Pall Ultipleat High Flow filters are a cutting-edge solution for demanding filtration systems. These filters offer advanced filtration capabilities that are essential in a wide range of applications. In this article, we will explore some of the key applications where Pall Ultipleat High Flow filters excel.

One of the primary applications of Pall Ultipleat High Flow filters is in the oil and gas industry. In this industry, the filtration of fluids is crucial to ensure the smooth operation of equipment and prevent damage. Pall Ultipleat High Flow filters are designed to handle high flow rates and provide excellent particle retention. This makes them ideal for removing contaminants from hydraulic fluids, lubricating oils, and fuel oils. By using these filters, companies can enhance the reliability and longevity of their equipment, ultimately reducing maintenance costs.

Another important application of Pall Ultipleat High Flow filters is in the pharmaceutical industry. In this industry, the filtration of liquids is critical to ensure the safety and efficacy of drugs. Pall Ultipleat High Flow filters are designed to meet the stringent requirements of pharmaceutical applications. They can effectively remove bacteria, viruses, and other microorganisms from process fluids, ensuring the production of high-quality drugs. Additionally, these filters are easy to install and maintain, making them a cost-effective solution for pharmaceutical companies.

Pall Ultipleat High Flow filters also find extensive use in the food and beverage industry. In this industry, the filtration of liquids is essential to maintain product quality and safety. These filters can effectively remove contaminants such as particles, bacteria, and yeast from process fluids, ensuring the production of safe and high-quality food and beverages. Moreover, Pall Ultipleat High Flow filters are designed to handle high flow rates, enabling efficient and continuous filtration processes. This is particularly important in large-scale food and beverage production facilities where high volumes of liquids need to be processed.

In addition to these industries, Pall Ultipleat High Flow filters are also widely used in water treatment applications. These filters can effectively remove particles, sediments, and other impurities from water, ensuring its safety and purity. Whether it is for municipal water treatment plants or industrial water purification systems, Pall Ultipleat High Flow filters provide reliable and efficient filtration solutions. They can handle high flow rates and offer long service life, reducing the need for frequent filter replacements.

Overall, Pall Ultipleat High Flow filters have a wide range of applications in various industries. Their advanced filtration capabilities make them an ideal choice for demanding systems. Whether it is in the oil and gas industry, pharmaceutical industry, food and beverage industry, or water treatment applications, these filters deliver exceptional performance. With their ability to handle high flow rates and provide excellent particle retention, Pall Ultipleat High Flow filters are a reliable and cost-effective solution for any filtration needs.

Features of Pall Ultipleat High Flow Filters

Pall Ultipleat High Flow filters are a cutting-edge solution for demanding filtration systems. These filters offer a range of features that make them highly effective in removing contaminants and ensuring the purity of fluids. In this article, we will explore some of the key features of Pall Ultipleat High Flow filters and how they contribute to their advanced filtration capabilities.

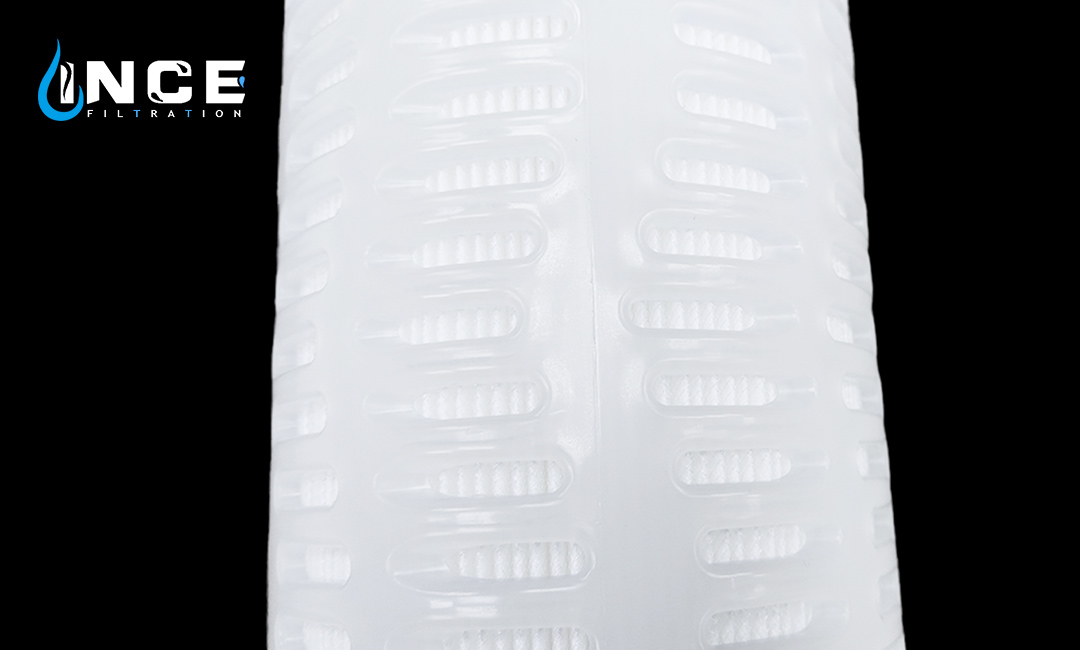

One of the standout features of Pall Ultipleat High Flow filters is their large surface area. These filters have a unique design that maximizes the available filtration area, allowing for high flow rates and efficient particle removal. The increased surface area also means that the filters have a longer lifespan, reducing the need for frequent replacements and saving on maintenance costs.

Another important feature of Pall Ultipleat High Flow filters is their high dirt-holding capacity. These filters are designed to capture and retain a large volume of contaminants, ensuring that the fluid passing through them remains clean and free from impurities. The high dirt-holding capacity is particularly beneficial in applications where there is a high concentration of contaminants or where the fluid needs to be filtered for an extended period.

Pall Ultipleat High Flow filters also feature a graded-density structure. This means that the filter media has varying levels of porosity, with finer pores on the outer layers and coarser pores towards the center. This design allows for efficient particle capture and prevents the filter from becoming clogged too quickly. The graded-density structure ensures that the filters maintain their performance over time, even in challenging operating conditions.

In addition to their advanced filtration capabilities, Pall Ultipleat High Flow filters are also highly versatile. These filters are available in a range of sizes and configurations, making them suitable for a wide variety of applications. Whether it is for industrial processes, water treatment, or pharmaceutical production, there is a Pall Ultipleat High Flow filter that can meet the specific requirements of the system.

Furthermore, Pall Ultipleat High Flow filters are designed for easy installation and maintenance. These filters are equipped with a unique bayonet lock system that allows for quick and secure filter replacement. The filters also have a built-in bypass valve that ensures continuous flow even during filter change-outs. This feature minimizes downtime and ensures uninterrupted operation of the filtration system.

In conclusion, Pall Ultipleat High Flow filters offer a range of features that make them an advanced filtration solution for demanding systems. With their large surface area, high dirt-holding capacity, graded-density structure, and versatility, these filters provide efficient and reliable particle removal. The easy installation and maintenance features further enhance their usability. Whether it is for industrial, water treatment, or pharmaceutical applications, Pall Ultipleat High Flow filters are a trusted choice for achieving clean and pure fluids.

Maintenance Tips for Pall Ultipleat High Flow Filters

Pall Ultipleat High Flow filters are known for their advanced filtration capabilities, making them ideal for demanding systems. These filters are designed to provide high flow rates and exceptional dirt-holding capacity, ensuring that your system operates at peak performance. However, like any filtration system, regular maintenance is crucial to ensure optimal performance and longevity.

One of the most important maintenance tips for Pall Ultipleat High Flow filters is to regularly monitor the pressure drop across the filter. Pressure drop is the difference in pressure between the inlet and outlet of the filter and is an indicator of the filter’s condition. As the filter accumulates dirt and debris, the pressure drop will increase. By monitoring the pressure drop, you can determine when it is time to replace the filter element.

To monitor the pressure drop, you will need a pressure gauge installed on the inlet and outlet of the filter. Start by recording the initial pressure drop when the filter is clean and new. As the filter operates, periodically check the pressure drop and compare it to the initial reading. If the pressure drop exceeds the recommended limit, it is time to replace the filter element.

Another important maintenance tip is to regularly inspect the filter element for any signs of damage or clogging. Inspect the element for any visible tears, holes, or deformities that may affect its performance. Additionally, check for any signs of clogging, such as a discolored or dirty element. If you notice any damage or clogging, replace the filter element immediately to prevent any potential system issues.

In addition to monitoring the pressure drop and inspecting the filter element, it is also important to follow the recommended filter change-out frequency. Pall Ultipleat High Flow filters have a recommended change-out frequency based on the specific application and operating conditions. It is crucial to adhere to these guidelines to ensure optimal filtration performance. Failure to change the filter element at the recommended intervals can lead to decreased system efficiency and potential damage.

When replacing the filter element, it is essential to follow proper installation procedures. Ensure that the element is correctly aligned and seated in the filter housing to prevent any bypass or leakage. Additionally, make sure to tighten all connections and seals to prevent any potential leaks.

Regularly cleaning the filter housing is another important maintenance tip. Over time, dirt and debris can accumulate in the housing, potentially affecting the performance of the filter. Use a mild detergent and water solution to clean the housing, ensuring that all dirt and debris are removed. Rinse thoroughly and allow the housing to dry completely before reinstalling the filter element.

Lastly, it is crucial to keep accurate records of all maintenance activities performed on the Pall Ultipleat High Flow filters. This includes recording the date of filter element replacement, pressure drop readings, and any observations or issues encountered during maintenance. These records will help you track the performance of the filters over time and identify any potential trends or recurring issues.

In conclusion, regular maintenance is essential to ensure optimal performance and longevity of Pall Ultipleat High Flow filters. By monitoring the pressure drop, inspecting the filter element, following recommended change-out frequencies, and properly cleaning the filter housing, you can ensure that your system operates at peak efficiency. Remember to keep accurate records of all maintenance activities to track the performance of the filters over time. With proper maintenance, Pall Ultipleat High Flow filters will continue to provide advanced filtration for your demanding systems.