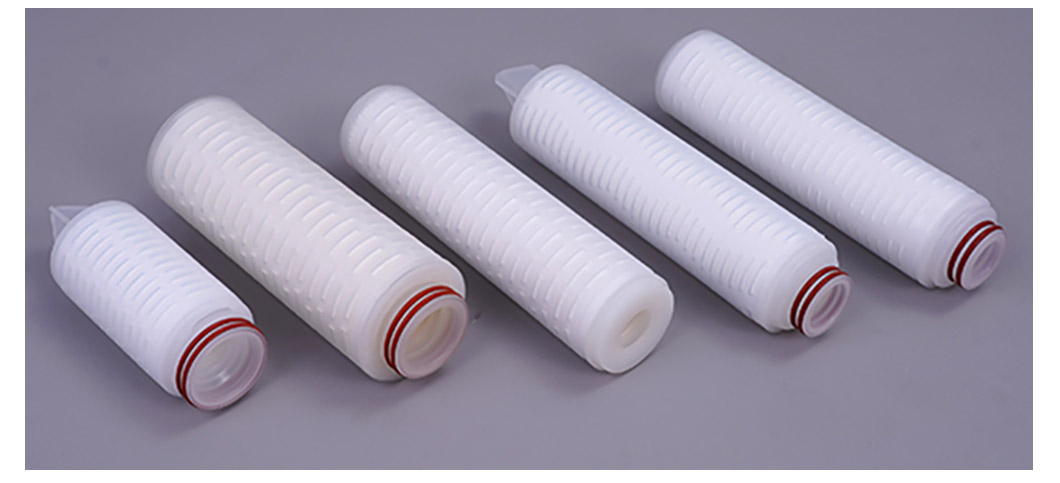

pleated filter element

pleated filter element

Using polypropylene composite filter membrane (polypropylene) as the main filter material, this type of filter element is an advanced fixed depth filter element with a nominal filtration accuracy range from 0.1 μm to 60 μm. The filter membrane is not affected by feed pressure fluctuations and affects filtration accuracy. Its unique advantages of low pressure difference, high throughput, good filtration accuracy and low economic cost are deeply loved by the majority of users.

Product features of pleated filter element

- Relative filtration accuracy, the interception rate reaches more than 90%

- Wide chemical compatibility, large flow rate and low pressure difference

- There is no medium shedding, and it complies with the standards of the pharmaceutical industry.

- Wide range of filtration precision to meet various application requirements

- Welded by hot melt process, it is strong and does not release any contaminant to the product.

- Chemical methods and online steam sterilization can be used.

- Can be washed and regenerated, economical and affordable.

Polypropylene microporous membrane filter element

The polypropylene filter element is a fixed-pore depth depth filter element using ultra-fine polypropylene fiber filter material as the filter medium. The filter material complies with the relevant FDA requirements. The filtration precision ranges from 0.1um to 60um. Its unique characteristics of low pressure difference, high flow rate and long service life make it the first choice product for pre-filtration. All-polypropylene construction provides stable performance and broad chemical compatibility.

Hydrophobic PTFE filter element

Hydrophobic polytetrafluoroethylene filter element, the filter medium is hydrophobic polytetrafluoroethylene microporous filter membrane: strong hydrophobicity, high retention rate, good chemical resistance and thermal stability, good strength, positive resistance and reverse pressure shock

Hydrophilic polytetrafluoroethylene filter element

Hydrophilic polytetrafluoroethylene filter element, the filter medium is hydrophilic polytetrafluoroethylene microporous filter membrane: stable hydrophilic performance, high retention rate, good chemical resistance and thermal stability, good strength, Resistant to forward and reverse pressure impacts.

Polyethersulfone filter element

The filter medium of the polyethersulfone filter element is the world’s most advanced polyethersulfone microporous filter membrane. The polyethersulfone membrane membrane pores account for more than 80% of the filter membrane volume and have a micropore opening rate. It has a unique micropore geometry. The filtration efficiency and flow rate of solutions that are difficult to filter are improved. It is made of a hot-melt combination of polyethersulfone and polypropylene support materials. It has no adhesive and is suitable for the chemical and pharmaceutical industries with strict requirements. Main features: unique hydrophilic properties, does not contain surfactants and surface lubricants, provides a high level of filtration precision and flow rate for filtered solutions, is suitable for a wide pH range, has low adsorption capacity for proteins and valuable biological agents, and has low retention It has high efficiency, good chemical resistance and thermal stability, good strength, and is resistant to forward and reverse pressure impacts.

Nylon filter element

Nylon filter element, the filter medium is a hydrophilic nylon microporous filter membrane, which is hot-melted with a combination of nylon and polypropylene support materials. It has no adhesive and no fiber shedding. It is suitable for the chemical and pharmaceutical industries with strict requirements. . Main features: stable hydrophilicity, strong flexibility, high retention rate, and good chemical resistance, especially suitable for filtration of organic solvents. Resistant to forward and reverse pressure impacts.

whatsapp:8618032835827

E-Mail: sales4@incefiltration.com