Pleated Membrane Cartridges: The Ultimate Solution for High-Efficiency Filtration

When precision, efficiency, and reliability are crucial in your filtration processes, pleated membrane cartridges are the go-to solution. These high-performance filters are designed to provide maximum surface area and long-lasting filtration, ensuring the removal of fine particles, contaminants, and microorganisms from liquids and gases. Whether you’re operating in the pharmaceutical, food and beverage, water treatment, or chemical industries, pleated membrane cartridges offer a superior filtration solution that ensures the purity and safety of your products.

In this article, we’ll explore the benefits, applications, and reasons why pleated membrane cartridges are an essential part of any high-efficiency filtration system.

What Are Pleated Membrane Cartridges?

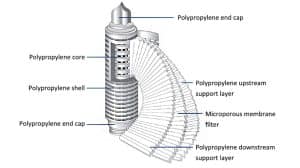

Pleated membrane cartridges are filtration devices made with pleated media, typically composed of materials like polypropylene, polyester, or PTFE (polytetrafluoroethylene). The pleated design increases the filter’s surface area without increasing its size, allowing for higher flow rates and extended service life. These cartridges are highly efficient in capturing fine particles, sediments, and microorganisms, making them ideal for applications requiring precision filtration.

Key Benefits of Pleated Membrane Cartridges

- High Filtration Efficiency

One of the most significant advantages of pleated membrane cartridges is their ability to filter out fine particles with high precision. These cartridges are typically rated to filter out particles as small as 0.1 microns, making them effective in removing bacteria, viruses, and other contaminants. Their high filtration efficiency makes them suitable for industries where product purity is non-negotiable, such as pharmaceuticals and food processing.

- Increased Surface Area

The pleated design of the membrane cartridges allows for a larger filtration surface area compared to flat media. This increased surface area means the cartridge can hold more contaminants before becoming clogged, leading to longer filtration cycles, reduced maintenance, and extended service life. This design also enables higher flow rates, ensuring efficient filtration without sacrificing performance.

- Durability and Longevity

Pleated membrane cartridges are built to withstand challenging environments and repeated use. Their durable construction makes them resistant to tearing, pressure, and chemical exposure. Whether used in water treatment plants or in the chemical industry, these cartridges provide reliable, long-term filtration with fewer replacements.

- Broad Chemical Compatibility

Pleated membrane cartridges are available in a range of materials, such as polypropylene and PTFE, which offer excellent chemical compatibility. This versatility makes them ideal for filtering aggressive liquids, acids, and solvents in industries like petrochemicals, pharmaceuticals, and food production. They can maintain their integrity and filtration performance even when exposed to harsh chemicals.

- Cost-Effective Filtration Solution

Due to their extended service life and high contaminant-holding capacity, pleated membrane cartridges reduce the frequency of cartridge changes, saving costs on replacements and labor. Their reusability (after cleaning in some applications) further enhances their value, making them a cost-effective choice for businesses that require continuous filtration.

Applications of Pleated Membrane Cartridges

- Pharmaceutical and Biotech Industries

In pharmaceutical and biotech manufacturing, ensuring the purity of liquids and gases is essential to prevent contamination of sensitive products. Pleated membrane cartridges are used to filter out bacteria, viruses, and fine particles from sterile liquids, injections, and other pharmaceutical solutions. Their high filtration efficiency helps maintain strict regulatory standards and product safety.

- Food and Beverage Filtration

In the food and beverage industry, filtration is critical for removing impurities and maintaining product quality. Pleated membrane cartridges are used to filter water, juices, oils, and other beverages, removing unwanted particles and microorganisms without affecting flavor or texture. They also play a key role in ensuring that production processes comply with health and safety regulations.

- Water Treatment and Purification

In municipal and industrial water treatment plants, pleated membrane cartridges are utilized to remove fine particles, sediments, and contaminants from water, ensuring that it meets quality standards for consumption or use in various applications. They are effective in removing bacteria, viruses, and other harmful microorganisms, providing safe and clean water.

- Chemical Processing

The chemical industry often requires filtration systems that can withstand aggressive chemicals and high temperatures. Pleated membrane cartridges made from materials like PTFE provide excellent chemical resistance, making them ideal for filtering solvents, acids, and other reactive compounds. They ensure that the final product is free from impurities, improving product quality and safety.

- Microelectronics and Semiconductor Manufacturing

Pleated membrane cartridges play a critical role in the microelectronics and semiconductor industries, where even the smallest contaminants can cause defects in sensitive components. These cartridges provide ultra-fine filtration to remove particles, ensuring the purity of process fluids and gases used in the manufacturing of microchips, circuit boards, and other electronic components.

Why Choose Pleated Membrane Cartridges?

- Superior Filtration Performance: The fine filtration capabilities of pleated membrane cartridges ensure the highest level of contaminant removal, protecting your processes and products from impurities.

- Long Service Life: With their increased surface area and high contaminant-holding capacity, these cartridges offer long-lasting filtration, reducing downtime and replacement costs.

- Versatile and Customizable: Pleated membrane cartridges can be tailored to suit specific applications, offering flexibility in terms of material, micron ratings, and dimensions.

- Sustainable and Cost-Effective: Their reusability and long service life contribute to a sustainable filtration solution that reduces waste and operational expenses.

Conclusion

If your business requires precise, reliable, and cost-effective filtration, pleated membrane cartridges are an ideal choice. Their combination of high filtration efficiency, durability, and versatility makes them suitable for a wide range of industries, from pharmaceuticals to water treatment. By investing in pleated membrane cartridges, you can ensure the purity of your products, improve operational efficiency, and reduce long-term costs.

Comprehensive Guide to Pleated Filter Cartridges: The Ultimate Filtration Solution

Discover the Ultimate Filtration Solution with PTFE Pleated Filter Cartridges

Hydrophobic PTFE Membrane Pleated Cartridges

Hydrophilic PTFE Membrane Pleated Filters

PES Pleated Filter Cartridge

Nylon pleated filter cartridge precision filtration