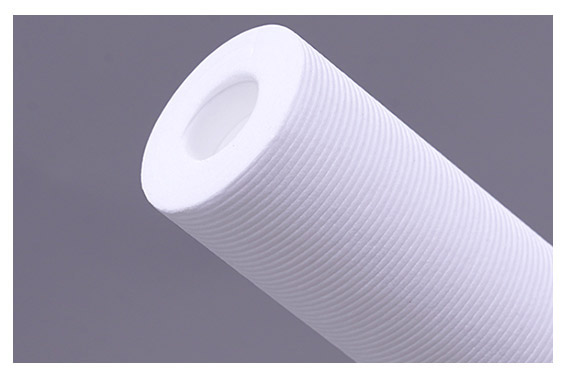

External transmission and internal density, good pollution interception effect, and long service life

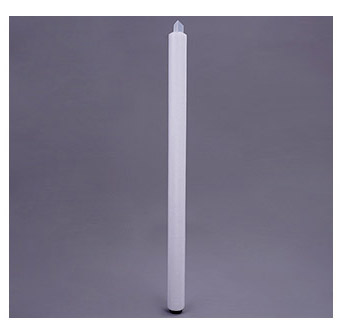

Melt-blown filter cartridges are tubular filter cartridges made of non-toxic, odorless PP particles after heating, melting, spinning, drawing, and forming.

|

Product name:

|

Melt-blown filter cartridge

|

|||

|

Filter rating:

|

1um, 3um, 5um,10um, 20um, 30um,60um

|

|||

|

PH:

|

1-13

|

|||

|

Pressure difference:

|

Forward 0.4Mpa

|

|||

|

Working temperature:

|

<70℃ under 0.25 Mpa

|

|||

|

Sterilization:

|

Tolerate 126C,30 minutes online steam sterilization

|

|||

|

Endotoxin:

|

The water extract of the filter column is tested by IAL, and the endotoxin content is less than 0.5 EU/ml

|

|||

External transmission and internal density, good pollution interception effect, and long service life

Internal thread structure, enhanced pressure resistance, and strong dirt-holding capacity

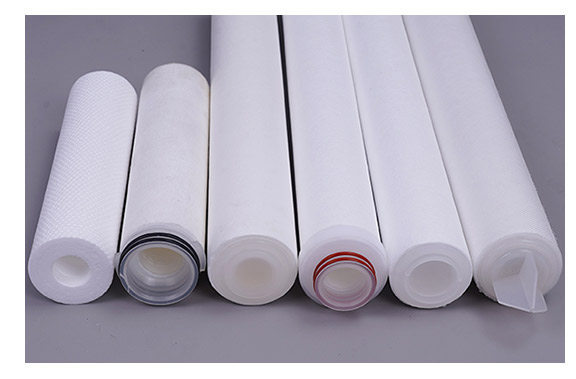

Various types of non-standard filter elements can be customized according to the different needs of customers.