PP Melt Blown: The Game-Changing Material for Filtration and Beyond

Polypropylene (PP) melt-blown fabric is one of the most versatile and widely used materials in various industries, especially in filtration, personal protective equipment (PPE), and industrial applications. This material has gained global recognition, particularly due to its critical role in manufacturing high-efficiency face masks during the COVID-19 pandemic. But beyond that, PP melt-blown fabric is a cornerstone for multiple industries, making it an ideal choice for those seeking optimal filtration solutions.

What is PP Melt Blown Fabric?

PP melt-blown fabric is made from polypropylene, a thermoplastic polymer that is melted and extruded through fine nozzles to produce a fine web of fibers. These fibers are randomly deposited, creating a non-woven material with excellent filtration properties. The fibers in melt-blown fabric are extremely fine, often in the submicron range, allowing the material to trap particles as small as bacteria and viruses.

Key Features of PP Melt Blown Fabric

- High Filtration Efficiency: One of the most outstanding characteristics of PP melt-blown fabric is its exceptional ability to filter both liquids and airborne particles. The fabric’s fine fibers create a complex matrix that traps contaminants, making it ideal for use in air filters, liquid filters, and face masks.

- Lightweight and Flexible: Despite its high filtration capabilities, PP melt-blown fabric is lightweight and flexible. This makes it suitable for various applications where flexibility is essential, such as in respirators and medical gowns.

- Water and Oil Absorbent: PP melt-blown fabric is also known for its excellent water and oil absorption properties, making it a perfect material for products used in cleaning spills or filtering oils in industrial processes.

- Cost-Effective Production: Since polypropylene is widely available and relatively inexpensive, the production of melt-blown fabric is cost-effective. This affordability makes it accessible for use in large-scale applications like HVAC filters and face masks.

Applications of PP Melt Blown Fabric

Due to its unique features, PP melt-blown fabric has diverse applications across several industries. Here are some of the key sectors where this material is used:

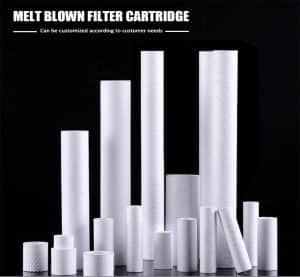

- Filtration Products: The filtration industry is where PP melt-blown fabric truly shines. It is commonly used in:

- Air Filters: The fine fibers efficiently trap airborne particles, making the material perfect for use in HVAC systems, air purifiers, and industrial air filters.

- Liquid Filters: In water and chemical filtration systems, PP melt-blown fabric can filter out fine contaminants. This makes it an ideal choice for water purification systems, oil filtration, and industrial fluid filtration.

- Face Masks: One of the most well-known uses of PP melt-blown fabric is in face masks, including surgical masks and N95 respirators. Its high filtration efficiency makes it essential for blocking airborne pathogens like bacteria and viruses.

- Medical and Healthcare Products: In the healthcare industry, PP melt-blown fabric is used in various personal protective equipment (PPE). Its high breathability, lightweight nature, and ability to filter harmful particles make it the material of choice for:

- Surgical Gowns: PP melt-blown fabric is often layered into medical gowns to protect against infections while maintaining comfort and flexibility.

- Surgical Drapes and Caps: It provides protection in sterile environments while allowing healthcare professionals to move freely.

- Wound Care Products: The fabric’s absorbent nature makes it suitable for wound dressings and surgical pads.

- Industrial Applications: PP melt-blown fabric is also used in a variety of industrial sectors:

- Oil Spill Cleanup: Its ability to absorb oil while repelling water makes it ideal for cleaning up oil spills or filtering oil from water.

- Insulation: The fine fibers trap air and provide excellent insulation properties, making it suitable for soundproofing and thermal insulation in construction and automotive applications.

- Hygiene Products: PP melt-blown fabric is used in disposable hygiene products such as diapers, sanitary pads, and wipes. Its absorbent nature and soft texture make it perfect for such applications.

The Role of PP Melt Blown Fabric in PPE

The demand for PP melt-blown fabric skyrocketed during the COVID-19 pandemic, especially for the production of surgical masks and N95 respirators. Its ability to filter out viruses and bacteria while allowing for breathability made it a vital material in fighting the pandemic. The fine fibers in the material trap particles as small as 0.1 microns, providing high protection levels, which is why it is a core component in many PPE products today.

Comparing PP Melt Blown with Other Filtration Materials

When choosing a filtration material, it’s essential to compare the benefits of PP melt-blown fabric with other materials:

- Glass Fiber: While glass fiber offers high filtration efficiency, it is much heavier and less flexible compared to PP melt-blown fabric. PP melt-blown fabric provides the same or better filtration performance but is more suitable for lightweight applications.

- Cotton and Other Natural Fibers: Natural fibers like cotton are biodegradable, but they don’t offer the same filtration efficiency as PP melt-blown fabric. Cotton tends to absorb moisture, which can reduce its filtration capability over time, whereas PP melt-blown fabric maintains its efficiency in both dry and wet conditions.

- Polyester: While polyester is another synthetic alternative, it does not match the fine fiber structure of PP melt-blown fabric, limiting its filtration abilities. PP melt-blown fabric offers superior performance, especially in high-efficiency applications like air and liquid filtration.

Why Choose PP Melt Blown Fabric for Your Filtration Needs?

Choosing PP melt-blown fabric for your filtration and protective equipment needs ensures you receive a high-quality, reliable, and cost-effective solution. Whether you are in the industrial, medical, or consumer goods sectors, the benefits of using PP melt-blown fabric include:

- High Filtration Efficiency: Its fine fiber structure ensures that contaminants are effectively trapped, whether airborne or in liquids.

- Durability: PP melt-blown fabric maintains its integrity even under challenging environmental conditions, offering long-lasting performance.

- Affordability: The relatively low cost of polypropylene makes this an affordable material for mass production, ideal for industries requiring bulk supplies.

- Wide Applicability: Its versatility allows it to be used in a range of applications, from PPE to industrial filters and cleaning products.

Conclusion

In summary, PP melt-blown fabric is a game-changer in the world of filtration and protective equipment. Its fine fiber structure, high filtration efficiency, and versatility across different industries make it an essential material in today’s market. Whether for air and liquid filtration or medical protection, investing in PP melt-blown fabric ensures high performance and reliable results. As industries continue to evolve, this material will undoubtedly remain a crucial component in filtration technologies and beyond.

Ensure that your business is equipped with the best filtration solutions by choosing PP melt-blown fabric, a material that delivers both quality and value across multiple applications.