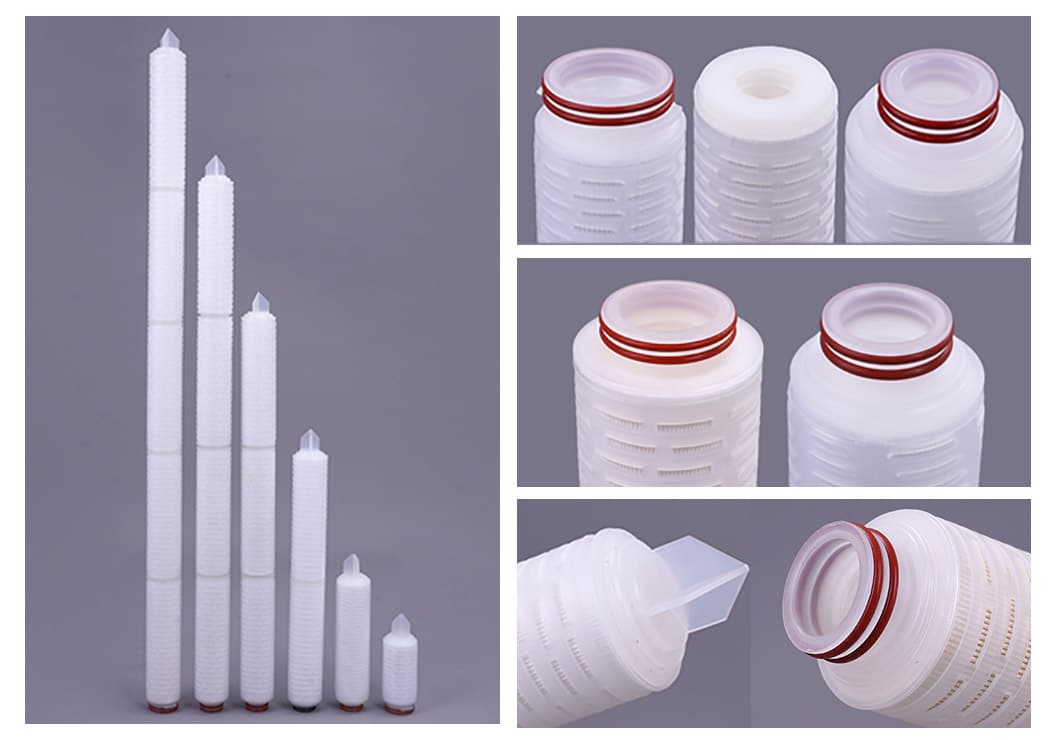

External transmission and internal density, good pollution interception effect, and long service life.

PP pleated filter cartridge is made of ultra-fine PP fiber membrane and non-woven fabric or woven nets, inner and outer support layers by pleating. The cage, core and end cap are fabricated by thermal bond technology. It contains no adhesive, no leakage, and no secondary pollution.

|

Product name:

|

PP pleated filter cartridge

|

|||

|

Media:

|

Polypropylene

|

|||

|

Filter rating:

|

0.1,0.22, 0.45, 1,3, 5, 10, 20, 30, 50um

|

|||

|

Length:

|

5″, 10″, 20″, 30″, 40″

|

|||

|

Outer diameter:

|

68mm

|

|||

|

Inside diameter:

|

28mm

|

|||

|

Connection type:

|

215 222 226 M30 M36

|

|||

External transmission and internal density, good pollution interception effect, and long service life.

All interfaces use ultrasonic welding. Customized composite membrane materials are specially added. The interception efficiency can reach 98%.

Various types of non-standard filter elements can be customized according to the different needs of customers.