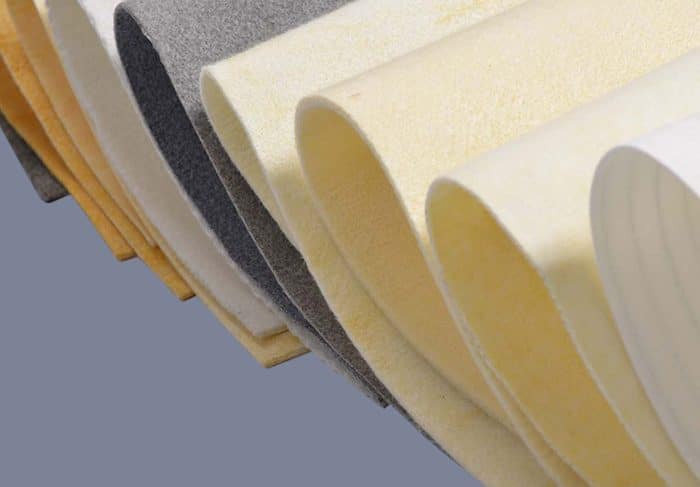

| Material | Felt |

| Specification | Diameter 105-500mm |

| Continuous operating temperature | 160 ° C |

| Instantaneous operating temperature | 190 ° C |

| Surface treatment | Waterproof; Oil; Anti-static; film. |

- Specifications

-

PPS dust filter bag is a kind of filter material which is made by PPS fiber (polyphenylene sulfide) through three-dimensional needling. It can be used for a long time at around 160 °C.

Other name: Dust filter bag; Felt dust filter bag.

The PPS fiber used in the PPS dust filter bag is also called polyphenylene sulfide fiber. Due to its special molecular structure, it has good chemical stability and strength and maintains its characteristics. It is especially effective in the flue gas environment with high sulfur content. It is suitable for high-acid flue gas filtration environment such as coal-fired boilers, electric power, and garbage incineration. The dust filter bag is the heart of the bag filter. During the operation of the bag filter, the cylindrical pulse filter bag is suspended vertically in the dust collector. The dust-containing gas enters the dust collector from the air inlet and passes through the baffle of the ash bucket. Part of the large particle dust in the gas is separated by the inertial force and falls directly into the ash bucket. The dust-containing gas enters the filter bag filtration zone of the tank, and most of the dust is trapped on the outer surface of the filter bag, and is clean. The gas enters the inside of the filter bag through the filter material, and the purified gas enters the upper tank through the filter bag mouth, and then is discharged from the air outlet. The cage inside the filter bag is used to support the filter bag to prevent the filter bag from collapsing, and it helps to remove and redistribute the dust cake.

PP Pleated Filter Cartridges Type

Material Felt Specification Diameter 105-500mm Continuous operating temperature 160 ° C Instantaneous operating temperature 190 ° C Surface treatment Waterproof; Oil; Anti-static; film. PP Pleated Filter Cartridges Advantage

Good porosity and ventilation; Long service life and good dust removal effect; Excellent resistance to hydrolysis and acid and alkali corrosion, pH range 1-14; It can be used under the condition that the oxygen content is less than 16% (but the temperature should be controlled within the proper range); The filtering wind speed can be selected from 1 to 1.5m/min, thus reducing the equipment volume and reducing the equipment cost.

PP Pleated Filter Cartridges Application :

Application:Mainly used in cement and building materials; Steel; Non-ferrous smelting; Coking refractory; Chemical; Mechanical casting; Crushing and polishing; Food; Medicine; Mill supporting and other industries.

About Us:

Hebei Ince Environmental Technology Co., Ltd is a professional factory is committed to R&D, design, produce and sales in the field of Products related to filtration field the main products :

Dust Filter Bag,Liquid Filter Bags, High Flow Filter Cartridges, Pleated Filters Cartridge, Membrane Filter Cartridges, Melt Blown Filter Cartridges, String Wound Cartridges,Filter Housing, Activated Carbon Filters Cartridge etc..

Ince high-class filter cartridges are widely used in Pre RO/ID Water Filtration, Industrial Water Treatment, Chemicals &Solvents, Power Plant Water Treatment, Food & Beverage, Microelectronics, Petrochemical etc.

Packaging & Shipping:

Packaging:

- Products are packed by shrink film. It can reduce abrasion when transport.

- Products are packed by high quality carton, suitable for long distance ocean freight transportation as well as changing

climate and with good resistance to moisture and shocks.

Delivery time:

- If this kind of products is in stock, the product will be sent for you 1-7days after payment.

- If this kind of products is not in stock, the products will take about 7-25 days to produce.

Shipping:Maritime; Railway; Air (DHL/UPS/TNT/FEDEX)

Contacts:

If you have interest in any kind of our product, warmly welcome your inquiry.

We will supply our best quality products and service for you.

Disclaimer:

This information has been provided as a general guide. It is the customer's responsibility to select the proper container for product and application compatibility.Tell us what you need, and we'll help you get quotes