Premium Rosin Press Extraction Bags – Get Pure & High-Yield Extracts

Benefits of Using Premium Rosin Press Extraction Bags

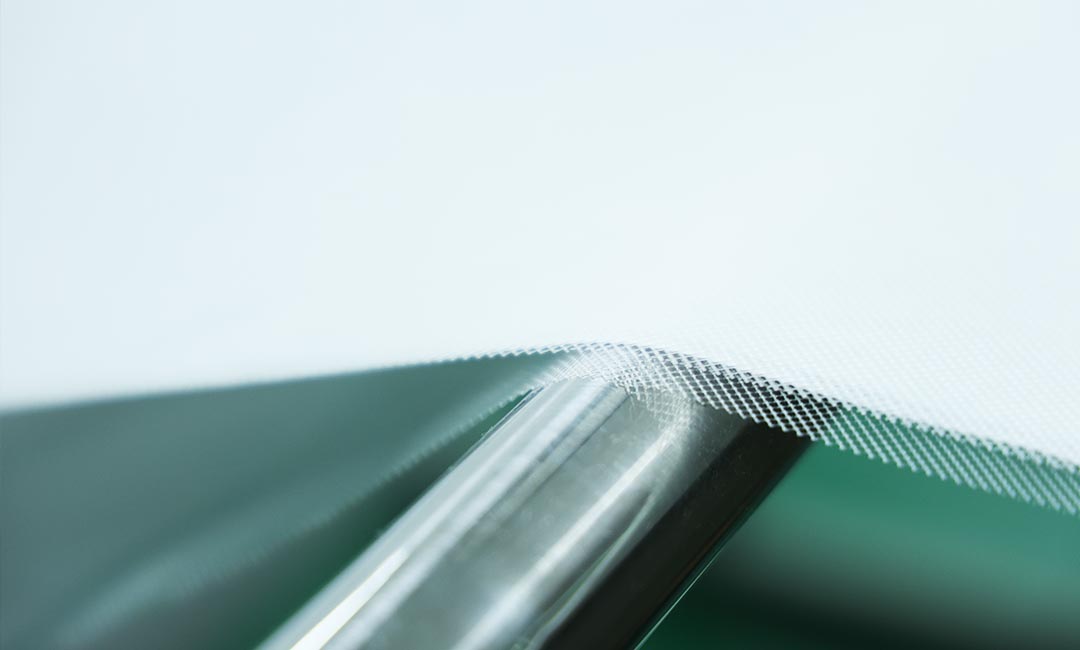

The use of premium rosin press extraction bags has become increasingly popular among both amateur and professional extractors, primarily due to the numerous benefits they offer in the extraction process. One of the most significant advantages of utilizing these specialized bags is their ability to enhance the purity of the final product. By employing high-quality materials and precise filtration, premium extraction bags effectively separate unwanted plant material from the desired resin, resulting in a cleaner and more potent extract. This purity is essential for consumers who prioritize quality and safety in their products, as it ensures that harmful contaminants and residual solvents are minimized.

In addition to improving purity, premium rosin press extraction bags also contribute to higher yields. The design of these bags allows for optimal pressure and heat distribution during the extraction process, which is crucial for maximizing the amount of resin extracted from the plant material. When using inferior bags, extractors may find that a significant portion of the valuable resin is left behind, leading to wasted product and lower overall returns. Conversely, premium bags are engineered to capture more of the resin, thereby increasing the yield and making the extraction process more efficient and cost-effective.

Moreover, the durability of premium rosin press extraction bags cannot be overlooked. Constructed from high-quality materials, these bags are designed to withstand the rigors of the extraction process, including high temperatures and pressures. This durability not only ensures that the bags can be reused multiple times, reducing waste and promoting sustainability, but it also means that extractors can rely on consistent performance throughout their operations. As a result, the investment in premium bags often pays off in the long run, as they provide a reliable solution that can withstand the demands of frequent use.

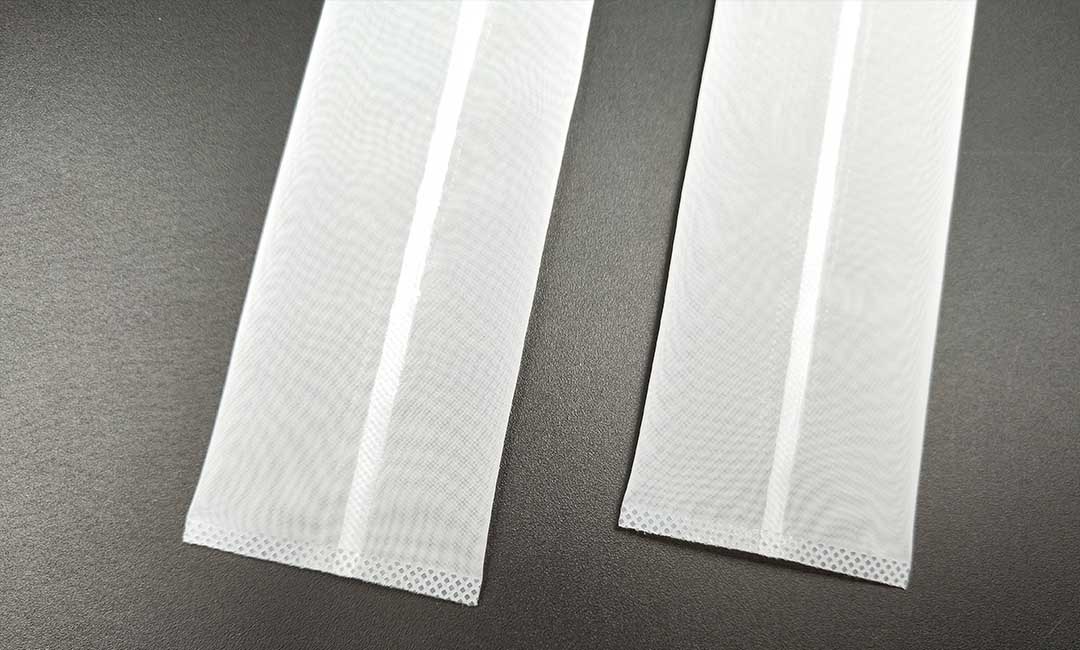

Another noteworthy benefit of using premium rosin press extraction bags is their versatility. These bags come in various sizes and micron ratings, allowing extractors to choose the most suitable option for their specific needs. Whether one is working with small batches or larger quantities, the availability of different sizes ensures that there is a bag that can accommodate any extraction requirement. Additionally, the varying micron ratings enable extractors to tailor their filtration process, allowing for the extraction of different types of concentrates, from full-spectrum oils to more refined products.

Furthermore, the ease of use associated with premium rosin press extraction bags enhances the overall extraction experience. Many of these bags are designed with user-friendly features, such as reinforced seams and easy-to-handle designs, which simplify the process for both novice and experienced extractors alike. This accessibility encourages more individuals to explore the art of rosin extraction, ultimately expanding the community of enthusiasts and professionals dedicated to producing high-quality extracts.

In conclusion, the benefits of using premium rosin press extraction bags are manifold, encompassing improved purity, higher yields, durability, versatility, and ease of use. As the demand for high-quality extracts continues to grow, investing in these specialized bags becomes increasingly essential for anyone looking to achieve optimal results in their extraction endeavors. By prioritizing quality and performance, extractors can ensure that they are producing the best possible products for their consumers, thereby solidifying their reputation in a competitive market.

How to Choose the Right Size for Your Extraction Needs

When it comes to extracting high-quality rosin, selecting the appropriate size of extraction bags is crucial for achieving optimal results. The size of the bag directly influences the yield and purity of the extracts, making it essential to understand the various factors that come into play when making this decision. To begin with, it is important to consider the amount of material you plan to process. Extraction bags come in a range of sizes, typically measured in microns, which correspond to the size of the material that can be contained within. A smaller bag, for instance, is ideal for processing smaller quantities of material, while larger bags are better suited for larger batches.

Moreover, the type of material being extracted also plays a significant role in determining the appropriate bag size. For instance, if you are working with flower, a bag size of 90 to 120 microns is often recommended, as it allows for the optimal flow of oils while filtering out unwanted plant material. Conversely, if you are extracting from hash or kief, a smaller micron size, such as 25 to 45 microns, may be more effective in capturing the finer trichomes and ensuring a purer extract. Therefore, understanding the characteristics of your starting material is essential in making an informed decision regarding bag size.

In addition to the type of material, the extraction method you choose can also influence the size of the bags you should use. For example, if you are utilizing a hydraulic press, you may require larger bags to accommodate the pressure and volume of material being processed. On the other hand, if you are using a smaller, manual press, smaller bags may suffice. It is also worth noting that the pressure applied during extraction can affect the efficiency of the process. Higher pressures may necessitate the use of larger bags to prevent tearing and ensure that the material is adequately contained.

Furthermore, it is advisable to consider the desired yield when selecting bag size. If your goal is to maximize the quantity of extract produced, larger bags may be beneficial, as they can hold more material and allow for a greater extraction surface area. However, it is essential to strike a balance between yield and purity. Using excessively large bags can lead to a dilution of the extract, as more plant material may be included in the final product. Therefore, it is crucial to assess your priorities and choose a bag size that aligns with your extraction goals.

Lastly, it is important to remember that experimentation is often key in finding the right bag size for your specific needs. Different materials and extraction methods may yield varying results, and what works for one individual may not necessarily work for another. By testing different bag sizes and monitoring the outcomes, you can refine your approach and ultimately achieve the highest quality extracts possible. In conclusion, selecting the right size for your extraction bags involves careful consideration of the material type, extraction method, desired yield, and personal experimentation. By taking these factors into account, you can ensure that your rosin extraction process is both efficient and effective, leading to pure and high-yield extracts that meet your expectations.

Tips for Maximizing Yield with Rosin Press Extraction Bags

Rosin press extraction bags are an essential tool for anyone looking to extract pure and high-yield concentrates from their cannabis or hemp plants. These bags are designed to contain the plant material while allowing the extracted oils to flow through, resulting in a clean and potent final product. However, to get the most out of your rosin press extraction bags, there are a few tips and tricks you should keep in mind.

First and foremost, it is crucial to choose the right size and micron rating for your extraction bags. The size of the bag will depend on the amount of material you are working with, while the micron rating will determine the size of the particles that can pass through the bag. For most applications, a micron rating of 90 or 120 is recommended, as this will allow for a good balance between yield and quality.

When loading your extraction bags, be sure to evenly distribute the material inside. This will help ensure that the pressure is evenly distributed during the pressing process, resulting in a more consistent extraction. Additionally, be mindful of the amount of material you are using – overloading the bag can lead to blowouts and a lower yield.

Another important tip for maximizing yield with rosin press extraction bags is to pre-press your material before placing it in the bag. This will help remove excess moisture and air pockets, resulting in a more efficient extraction process. Additionally, pre-pressing can help increase the surface area of the material, allowing for better contact with the heat and pressure during pressing.

During the pressing process, it is important to monitor the temperature and pressure carefully. Different strains and material types may require different settings to achieve optimal results. Generally, a temperature range of 180-220 degrees Fahrenheit and a pressure of 600-1500 psi are recommended for most applications. However, it is always best to experiment and find the settings that work best for your specific material.

After pressing, be sure to properly store and cure your extracts. Storing them in a cool, dark place will help preserve their potency and flavor. Curing your extracts for a few days to a week can also help improve their overall quality and taste.

In conclusion, rosin press extraction bags are a valuable tool for anyone looking to extract pure and high-yield concentrates from their cannabis or hemp plants. By following these tips and tricks, you can maximize your yield and produce top-quality extracts every time. Remember to choose the right size and micron rating for your bags, evenly distribute your material, pre-press before pressing, monitor temperature and pressure, and properly store and cure your extracts. With a little practice and experimentation, you can become a master at using rosin press extraction bags and enjoy the benefits of clean, potent concentrates.

Common Mistakes to Avoid When Using Extraction Bags

When utilizing premium rosin press extraction bags, it is essential to be aware of common mistakes that can hinder the quality and yield of your extracts. Understanding these pitfalls can significantly enhance your extraction process, ensuring that you achieve the purest and most potent results possible. One of the most frequent errors is using the wrong size of extraction bags. Selecting bags that are either too small or too large for your material can lead to inefficient extraction. If the bag is too small, it may become overstuffed, resulting in uneven pressure distribution and suboptimal yields. Conversely, using a bag that is too large can cause the material to shift during the pressing process, leading to contamination and a diluted extract. Therefore, it is crucial to choose the appropriate bag size that corresponds to the amount of material you intend to process.

Another common mistake involves neglecting the importance of proper material preparation. Many users overlook the necessity of adequately breaking down their starting material before placing it in the extraction bag. Failing to grind or break up the material can lead to uneven extraction, as larger pieces may not release their essential oils effectively. By ensuring that your material is finely ground, you can maximize surface area exposure, which in turn enhances the extraction process. Additionally, it is advisable to pre-press the material lightly before placing it in the extraction bag. This step can help to compact the material, allowing for a more uniform extraction and higher yield.

Moreover, temperature control is a critical factor that is often underestimated. Many individuals do not monitor the temperature of their rosin press closely, which can lead to either overheating or underheating the material. Excessive heat can degrade the quality of the extract, resulting in a loss of flavor and potency, while insufficient heat may prevent the extraction of essential oils altogether. It is essential to find the optimal temperature range for your specific material, as different strains and types of plant matter may require varying temperatures for ideal extraction. Utilizing a thermometer to monitor the heat during the pressing process can help ensure that you achieve the best possible results.

In addition to temperature, pressure is another vital element that should not be overlooked. Many users either apply too much pressure or not enough, both of which can adversely affect the extraction quality. Excessive pressure can lead to the extraction of undesirable compounds, while insufficient pressure may result in low yields. It is advisable to start with moderate pressure and gradually increase it as needed, allowing you to find the sweet spot that maximizes yield without compromising quality.

Lastly, one of the most significant mistakes is failing to clean the extraction bags properly after each use. Residual material left in the bags can contaminate future extractions, leading to inconsistent results. It is essential to thoroughly clean and dry your extraction bags after each session to maintain their integrity and ensure that they perform optimally in subsequent extractions. By avoiding these common mistakes, you can enhance your rosin extraction process, yielding pure and high-quality extracts that meet your expectations. Ultimately, a careful approach to using extraction bags will not only improve your results but also elevate your overall experience in the world of rosin extraction.