Pressing Rosin Without a Bag: Pros, Cons, and Best Practices

Advantages of Pressing Rosin Without a Bag

Pressing rosin without a bag has gained popularity among enthusiasts and professionals alike, primarily due to its unique advantages that enhance the overall extraction process. One of the most significant benefits of this method is the elimination of the need for a filter bag, which can simplify the pressing procedure. Without a bag, the process becomes more straightforward, allowing for a quicker setup and less equipment to manage. This simplicity can be particularly appealing for those who are new to rosin extraction or for those who prefer a more streamlined approach.

Moreover, pressing rosin without a bag can lead to a higher yield of the desired product. When using a bag, some of the resin may become trapped within the fibers, resulting in a loss of material that could otherwise be extracted. By omitting the bag, the entire amount of resin is subjected to pressure, maximizing the extraction potential. This can be especially beneficial for those working with high-quality flower or trim, where every bit of resin is valuable. Consequently, the efficiency of the extraction process is significantly improved, making it a more cost-effective option for producers.

In addition to increased yield, pressing rosin without a bag can also enhance the purity of the final product. When using a bag, there is a risk of introducing contaminants or unwanted plant material into the rosin. By pressing directly, the risk of contamination is minimized, resulting in a cleaner and more refined product. This is particularly important for consumers who prioritize quality and purity in their concentrates. Furthermore, the absence of a bag allows for a more direct interaction between the heat and the plant material, which can lead to a more flavorful and aromatic end product.

Another advantage of this method is the ability to experiment with different pressing techniques and parameters. Without the constraints of a bag, users can easily adjust variables such as temperature and pressure to find the optimal conditions for their specific material. This flexibility can lead to a greater understanding of the extraction process and ultimately result in a more tailored product that meets individual preferences. Additionally, this experimentation can foster creativity, encouraging users to explore various strains and materials to discover unique flavor profiles and effects.

However, it is essential to acknowledge that pressing rosin without a bag does come with its own set of challenges. For instance, the absence of a filter can make it more difficult to separate the rosin from any residual plant material. This may require additional steps in the post-pressing process, such as straining or filtering, to achieve the desired level of purity. Nevertheless, many users find that the benefits outweigh these challenges, particularly when they become more adept at managing the extraction process.

In conclusion, pressing rosin without a bag offers several advantages that can enhance both the efficiency and quality of the extraction process. The elimination of the bag simplifies the procedure, increases yield, and improves the purity of the final product. Additionally, the flexibility to experiment with different techniques allows for a more personalized approach to rosin production. While there are challenges associated with this method, the potential rewards make it an appealing option for those looking to optimize their rosin extraction experience. As the popularity of this technique continues to grow, it is likely that more users will explore the benefits of pressing rosin without a bag, further advancing the craft of rosin production.

Disadvantages of Bagless Rosin Pressing

Pressing rosin without a bag, while appealing for its simplicity and efficiency, presents several disadvantages that warrant careful consideration. One of the primary concerns is the potential for contamination. When using a bag, the material is contained, minimizing the risk of unwanted plant material or impurities mixing with the final product. In contrast, bagless pressing exposes the rosin to the pressing surface and surrounding environment, increasing the likelihood of contaminants affecting the purity and quality of the extract. This can be particularly problematic for consumers who prioritize clean, solvent-free products.

Another significant drawback of bagless rosin pressing is the difficulty in achieving consistent results. Bags provide a level of filtration that helps to separate the desirable compounds from the less desirable ones, such as chlorophyll and waxes. Without this filtration, the resulting rosin may vary in color, texture, and potency from batch to batch. This inconsistency can be frustrating for both producers and consumers, as it undermines the reliability of the product and can lead to dissatisfaction.

Moreover, the absence of a bag can lead to a lower yield of rosin. When pressing with a bag, the material is contained, allowing for more efficient extraction of the resinous compounds. In a bagless setup, some of the valuable oils may be lost during the pressing process, as they can seep into the pressing plates or become trapped in the plant material. This loss not only affects the quantity of the final product but can also impact its overall quality, as the most desirable compounds may not be fully extracted.

Additionally, bagless pressing can result in a more labor-intensive cleanup process. Without a bag to catch the residual plant material, producers may find themselves spending more time and effort cleaning the pressing plates and surrounding area. This added labor can detract from the overall efficiency of the pressing process, making it less appealing for those looking to streamline their operations.

Furthermore, the lack of a bag can complicate the pressing process itself. For those who are new to rosin pressing, the absence of a bag may lead to confusion regarding the optimal temperature and pressure settings. Bags often provide a buffer that helps to regulate these variables, allowing for a more controlled extraction. Without this buffer, inexperienced users may struggle to find the right balance, resulting in subpar rosin that fails to meet their expectations.

Lastly, the aesthetic appeal of the final product can be compromised when pressing without a bag. Rosin pressed with bags typically exhibits a more refined appearance, with a clearer color and smoother texture. In contrast, bagless rosin may appear darker and less visually appealing, which can influence consumer perception and marketability. This aspect is particularly important in a competitive market where presentation plays a crucial role in attracting buyers.

In conclusion, while bagless rosin pressing offers certain advantages, such as reduced material costs and simplified processes, the disadvantages cannot be overlooked. From contamination risks and inconsistent yields to increased cleanup efforts and aesthetic concerns, these factors highlight the importance of weighing the pros and cons before deciding on a pressing method. For those committed to producing high-quality rosin, utilizing bags may ultimately prove to be the more effective and reliable choice.

Best Practices for Bagless Rosin Extraction

Rosin extraction has become increasingly popular among cannabis enthusiasts and home growers as a safe and effective way to produce high-quality concentrates. One of the key decisions that extractors must make when pressing rosin is whether to use a filter bag or to press the material without one. While using a filter bag can help to contain the material and prevent plant matter from contaminating the final product, some extractors prefer to press rosin without a bag for a variety of reasons.

One of the main advantages of pressing rosin without a bag is that it allows for a more direct extraction process. When using a filter bag, some of the terpenes and cannabinoids can get trapped in the bag, resulting in a less potent final product. By pressing rosin without a bag, extractors can ensure that they are getting the most out of their material and producing a concentrate that is rich in flavor and potency.

Another benefit of pressing rosin without a bag is that it can be a more cost-effective method. Filter bags can be expensive, especially if you are pressing large quantities of material on a regular basis. By eliminating the need for a filter bag, extractors can save money and reduce their overall production costs.

However, pressing rosin without a bag does come with its own set of challenges. One of the main drawbacks is that it can be more difficult to contain the material and prevent plant matter from contaminating the final product. Without a filter bag, extractors must be careful to properly prepare their material and ensure that it is well-contained during the pressing process.

To address this issue, there are a few best practices that extractors can follow when pressing rosin without a bag. First and foremost, it is important to properly prepare the material before pressing. This includes removing any stems, seeds, or other contaminants that could affect the quality of the final product. Additionally, it is recommended to use a pre-press mold to help compact the material and ensure that it stays in place during the pressing process.

Another best practice for pressing rosin without a bag is to use a high-quality press that is capable of applying even pressure across the entire surface of the material. Uneven pressure can result in an uneven extraction, leading to a lower-quality final product. By using a press that is specifically designed for rosin extraction, extractors can ensure that they are getting the most out of their material and producing a concentrate that is consistent in quality.

In conclusion, pressing rosin without a bag can be a cost-effective and efficient method for producing high-quality concentrates. While there are some challenges associated with this approach, following best practices such as properly preparing the material and using a high-quality press can help extractors overcome these obstacles and produce a final product that is rich in flavor and potency. By carefully considering the pros and cons of pressing rosin without a bag, extractors can make an informed decision that best suits their needs and preferences.

Comparing Bagged vs. Bagless Rosin Techniques

The process of extracting rosin, a solventless concentrate derived from cannabis, has gained significant popularity among enthusiasts and producers alike. Traditionally, this extraction method has relied on the use of bags to contain the plant material during the pressing process. However, the emergence of bagless techniques has sparked a debate among users regarding the efficacy and quality of the final product. To understand the nuances of these two approaches, it is essential to compare the bagged and bagless methods, examining their respective advantages and disadvantages.

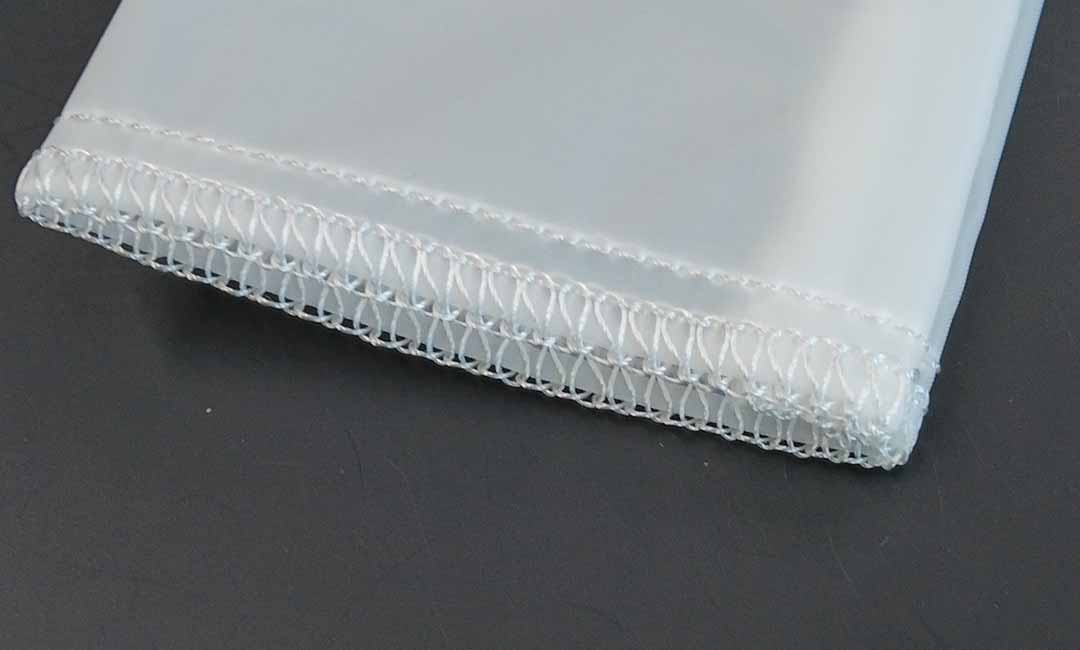

One of the primary benefits of using bags in the rosin extraction process is the ability to filter out unwanted plant material. Bags, typically made from food-grade nylon or similar materials, serve as a barrier that allows only the desired resin to pass through while trapping larger particles, such as plant matter and contaminants. This filtration can result in a cleaner, more refined product, which is particularly appealing to consumers seeking high-quality concentrates. Furthermore, the use of bags can help maintain the integrity of the rosin by preventing it from coming into direct contact with the heat plates, thereby reducing the risk of scorching or degrading the terpenes and cannabinoids.

Conversely, the bagless technique offers its own set of advantages that can be appealing to certain users. One notable benefit is the simplicity and speed of the process. Without the need for bags, the extraction can be executed more quickly, allowing for a more efficient workflow. Additionally, bagless pressing can yield a higher quantity of rosin, as there is no material loss associated with the bags themselves. This can be particularly advantageous for those working with larger quantities of plant material, as it maximizes the overall yield.

However, the bagless method is not without its drawbacks. One significant concern is the potential for contamination, as the absence of a filtering barrier increases the likelihood of plant material mixing with the final product. This can lead to a less desirable texture and flavor profile, which may not meet the expectations of discerning consumers. Moreover, the risk of scorching the rosin is heightened in bagless pressing, as the direct contact with heat plates can lead to uneven heating and degradation of the valuable compounds within the extract.

When considering which method to employ, it is crucial to weigh these pros and cons in relation to individual goals and preferences. For those prioritizing purity and quality, the bagged method may be the more suitable choice, as it provides a level of filtration that can enhance the overall experience. On the other hand, users who value efficiency and higher yields may find the bagless technique more appealing, despite the potential trade-offs in quality.

In conclusion, both bagged and bagless rosin extraction techniques have their merits and limitations. The choice between the two ultimately depends on the specific needs and priorities of the user. By understanding the differences between these methods, individuals can make informed decisions that align with their desired outcomes. Whether one opts for the meticulous filtration of bagged pressing or the expediency of bagless extraction, the key lies in mastering the technique to achieve the best possible results. As the rosin industry continues to evolve, ongoing experimentation and innovation will likely lead to further advancements in both methods, ultimately benefiting consumers and producers alike.