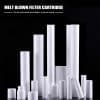

PTFE hydrophilic pleated filter cartridges

The precision requirements for PTFE hydrophilic pleated filter cartridges can vary depending on the specific application and desired filtration performance. However, some general precision requirements for these cartridges may include:

Filtration Efficiency: PTFE hydrophilic pleated filter cartridges are typically designed to provide high filtration efficiency. The precision requirement for filtration efficiency can be specified in terms of the percentage of particles or contaminants that the cartridge can remove from the fluid being filtered. For example, a high precision requirement may be to achieve a filtration efficiency of 99.99% for certain particle sizes.

Pore Size: PTFE hydrophilic pleated filter cartridges have a specific pore size that determines the size of particles that can be retained by the filter media. The precision requirement for pore size can be specified in terms of the maximum allowable particle size that should pass through the filter. For example, a precision requirement may be to have a pore size of 0.2 microns, meaning that no particles larger than 0.2 microns should pass through the filter.

Flow Rate: The flow rate through the PTFE hydrophilic pleated filter cartridge can also be a precision requirement. This requirement can be specified in terms of the maximum allowable flow rate that the cartridge should handle while maintaining the desired filtration efficiency. For example, a precision requirement may be to achieve a flow rate of 10 gallons per minute (GPM) without compromising the filtration performance.

Pressure Drop: The pressure drop across the PTFE hydrophilic pleated filter cartridge is another precision requirement that can be specified. Pressure drop refers to the decrease in pressure as the fluid passes through the filter media. The precision requirement for pressure drop can be specified in terms of the maximum allowable pressure drop that should occur across the filter cartridge. For example, a precision requirement may be to have a pressure drop of less than 10 psi.

It is important to note that these precision requirements can vary depending on the specific application and industry standards. Therefore, it is recommended to consult with the filter cartridge manufacturer or supplier to determine the precise requirements for a particular application.

whatsapp:8618032835827

E-Mail: sales4@incefiltration.com