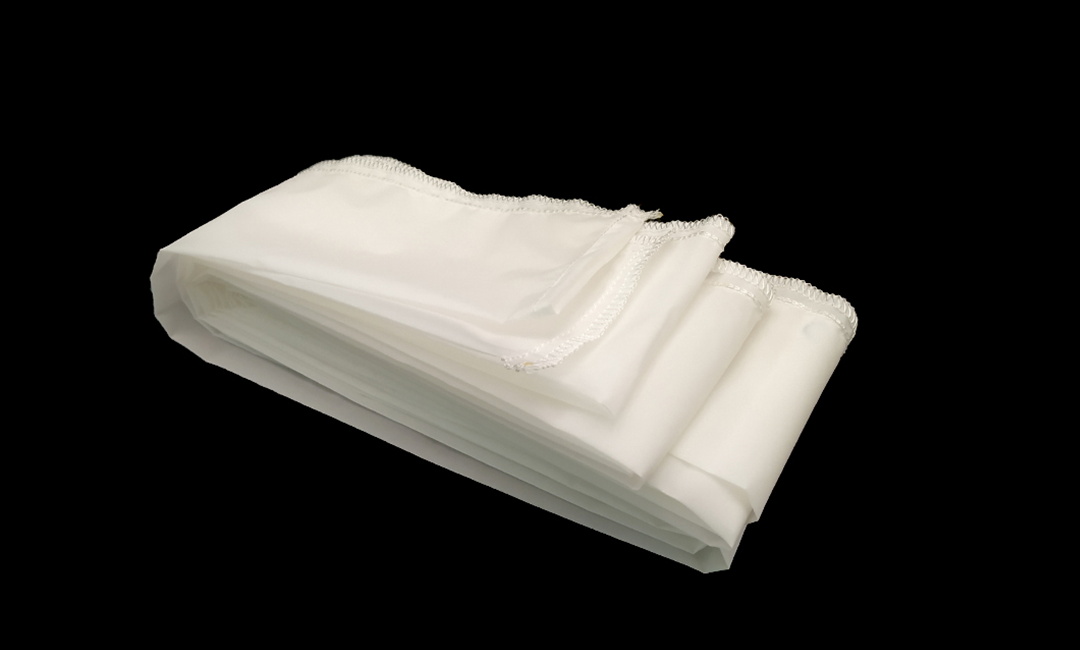

Rosin Industries 160 Micron Nylon Screen Press Bag – High-Quality & Durable

Benefits of Using 160 Micron Nylon Screen Press Bags in Rosin Extraction

The process of rosin extraction has gained significant popularity in recent years, particularly among those seeking a solventless method to obtain high-quality concentrates. One of the essential tools in this process is the use of nylon screen press bags, specifically those with a 160-micron mesh size. These bags offer a range of benefits that enhance the efficiency and quality of rosin extraction, making them a preferred choice for both amateur and professional extractors.

To begin with, the 160-micron nylon screen press bags are designed to strike an optimal balance between filtration and yield. The mesh size is fine enough to effectively separate the plant material from the extracted rosin, ensuring that only the purest product is obtained. This level of filtration is crucial, as it minimizes the presence of unwanted contaminants, such as plant fats and waxes, which can negatively impact the flavor and overall quality of the final product. Consequently, users can expect a cleaner and more potent concentrate, which is particularly important for those who prioritize purity in their extracts.

Moreover, the durability of these nylon screen press bags cannot be overstated. Constructed from high-quality materials, they are designed to withstand the pressures and temperatures involved in the rosin extraction process. This resilience not only ensures that the bags maintain their structural integrity during use but also extends their lifespan, making them a cost-effective investment for extractors. Unlike lower-quality alternatives that may tear or degrade after a few uses, the 160-micron nylon bags can endure repeated extractions without compromising their performance.

In addition to their durability, these bags are also easy to clean and maintain. After the extraction process, users can simply rinse the bags with warm water to remove any residual plant material. This ease of cleaning is a significant advantage, as it allows for quick turnaround times between extractions, thereby increasing overall productivity. Furthermore, the ability to reuse these bags multiple times not only reduces waste but also contributes to a more sustainable extraction practice.

Another noteworthy benefit of using 160-micron nylon screen press bags is their versatility. They can be utilized for various types of plant materials, including flowers, hash, and kief, making them suitable for a wide range of extraction methods. This adaptability allows extractors to experiment with different materials and techniques, ultimately leading to a more diverse product line. As a result, users can cater to a broader audience, enhancing their marketability and potential profitability.

Additionally, the use of these bags can significantly improve the overall extraction process. The precise mesh size allows for optimal oil flow, which not only increases the yield but also enhances the efficiency of the extraction. This means that extractors can achieve more with less material, maximizing their resources and minimizing waste. The combination of high yield and quality makes the 160-micron nylon screen press bags an indispensable tool for anyone serious about rosin extraction.

In conclusion, the benefits of using 160-micron nylon screen press bags in rosin extraction are manifold. From their ability to produce high-quality, pure concentrates to their durability and ease of maintenance, these bags represent a valuable asset for both novice and experienced extractors alike. Their versatility and efficiency further solidify their status as a preferred choice in the industry, making them an essential component of any successful rosin extraction setup. As the demand for high-quality concentrates continues to grow, investing in reliable tools such as these bags will undoubtedly yield positive results for extractors seeking to elevate their craft.

How to Choose the Right Rosin Press Bag for Your Needs

When it comes to extracting rosin, the choice of press bag is crucial for achieving optimal results. The Rosin Industries 160 Micron Nylon Screen Press Bag stands out as a high-quality and durable option, but selecting the right bag for your specific needs requires careful consideration of several factors. First and foremost, it is essential to understand the role of micron size in the extraction process. Micron size refers to the diameter of the mesh openings in the bag, which directly influences the quality and yield of the rosin produced. A 160-micron bag, for instance, strikes a balance between allowing essential oils to pass through while filtering out unwanted plant material, making it a popular choice among both novice and experienced extractors.

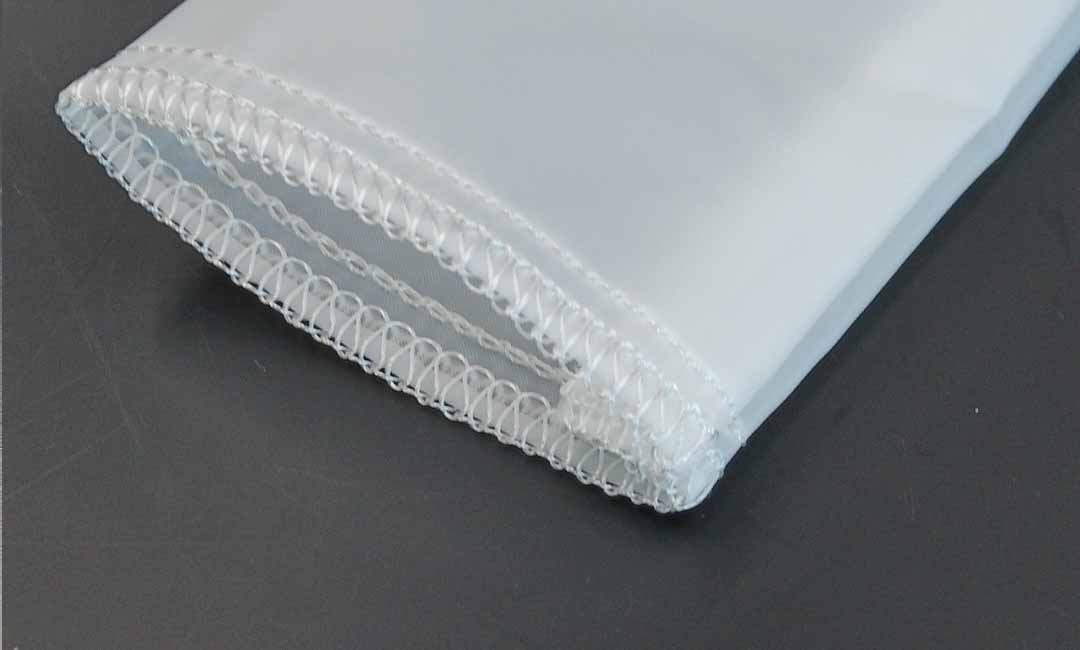

In addition to micron size, the material of the press bag plays a significant role in its performance. The Rosin Industries bag is crafted from high-quality nylon, known for its durability and resistance to wear and tear. This durability is particularly important, as the extraction process can be demanding, subjecting the bag to high pressures and temperatures. A robust material ensures that the bag can withstand these conditions without compromising its integrity, thereby enhancing the overall efficiency of the extraction process. Furthermore, nylon is less likely to impart any unwanted flavors or contaminants into the rosin, ensuring a pure and high-quality end product.

Another critical aspect to consider is the size of the press bag. The Rosin Industries 160 Micron Nylon Screen Press Bag comes in various sizes, allowing users to select one that best fits their pressing equipment and the quantity of material they intend to process. A properly sized bag not only facilitates a more efficient extraction but also minimizes the risk of spillage or contamination. Therefore, it is advisable to measure your press and consider the volume of material you typically work with before making a purchase.

Moreover, ease of use and cleaning are essential factors that should not be overlooked. The Rosin Industries bag is designed for user convenience, featuring a straightforward design that simplifies the filling and pressing process. After extraction, cleaning the bag is equally important to maintain its longevity and performance. Nylon bags are generally easy to clean, and the Rosin Industries bag is no exception. A simple rinse with warm water and mild soap can effectively remove any residual plant material, ensuring that the bag remains in optimal condition for future use.

Additionally, it is beneficial to consider the reputation of the manufacturer when selecting a press bag. Rosin Industries has established itself as a trusted name in the industry, known for producing high-quality products that meet the needs of extractors. Customer reviews and testimonials can provide valuable insights into the performance and reliability of the bag, helping you make an informed decision.

In conclusion, choosing the right rosin press bag involves a careful evaluation of micron size, material, size compatibility, ease of use, and manufacturer reputation. The Rosin Industries 160 Micron Nylon Screen Press Bag exemplifies a high-quality and durable option that meets these criteria, making it an excellent choice for those looking to enhance their rosin extraction process. By taking the time to assess your specific needs and preferences, you can ensure that you select a press bag that will deliver optimal results and contribute to a successful extraction experience.

Maintenance Tips for High-Quality Nylon Screen Press Bags

Maintaining the quality and durability of your Rosin Industries 160 Micron Nylon Screen Press Bag is essential for ensuring optimal performance and longevity. Proper care not only enhances the efficiency of the extraction process but also preserves the integrity of the bag itself. To begin with, it is crucial to understand the importance of cleaning the bag after each use. Residual materials can accumulate and lead to blockages, which may hinder the extraction process in future uses. Therefore, rinsing the bag with warm water immediately after use is highly recommended. This initial rinse helps to remove any leftover plant material or oils, preventing them from hardening and becoming more difficult to clean later.

Following the rinse, a gentle soap solution can be employed to further cleanse the bag. It is advisable to use a mild detergent that is free from harsh chemicals, as these can degrade the nylon fibers over time. When applying the soap, use a soft cloth or sponge to gently scrub the surface of the bag, paying particular attention to the seams and corners where residue may be trapped. After scrubbing, thoroughly rinse the bag again with warm water to ensure that all soap is removed. This step is vital, as any remaining soap can interfere with future extractions, potentially altering the flavor and quality of the final product.

Once the bag is clean, proper drying techniques should be employed to prevent mold and mildew growth. It is best to air dry the bag in a well-ventilated area, away from direct sunlight, which can cause the nylon to weaken over time. Hanging the bag upside down can facilitate drainage and ensure that any residual moisture evaporates completely. Avoid using heat sources such as hair dryers or radiators, as excessive heat can damage the fabric and compromise its structural integrity.

In addition to regular cleaning, it is important to inspect the bag for any signs of wear and tear. Over time, even the highest quality nylon screen press bags may develop small holes or frays, particularly in high-stress areas. Regular inspections allow for early detection of these issues, enabling timely repairs or replacements. If minor damage is found, consider using a nylon repair patch or sewing kit to mend the bag, ensuring that it remains functional for future use.

Furthermore, proper storage of the nylon screen press bag is essential for maintaining its quality. When not in use, store the bag in a cool, dry place, preferably in a protective case or container to prevent dust accumulation and physical damage. Avoid folding the bag in a way that creates creases, as this can weaken the fabric over time. Instead, roll the bag gently to preserve its shape and integrity.

Lastly, it is advisable to follow the manufacturer’s guidelines for care and maintenance, as these recommendations are tailored specifically for the Rosin Industries 160 Micron Nylon Screen Press Bag. By adhering to these maintenance tips, users can ensure that their screen press bags remain high-quality and durable, ultimately enhancing the efficiency of their extraction processes and prolonging the lifespan of their equipment. In conclusion, a commitment to proper care and maintenance will yield significant benefits, allowing for consistent and high-quality results in every extraction endeavor.

Comparing Different Micron Sizes: Why 160 Micron is Ideal for Rosin Industries

When it comes to extracting rosin, the choice of micron size plays a crucial role in determining the quality and yield of the final product. Among the various options available, the 160 micron nylon screen press bag stands out as an ideal choice for many in the rosin industry. This specific micron size strikes a balance between filtration efficiency and oil yield, making it a preferred option for both novice and experienced extractors alike.

To understand why 160 microns is particularly advantageous, it is essential to consider the function of micron screens in the extraction process. Micron screens serve to filter out unwanted plant material while allowing the desirable resinous oils to pass through. A micron size that is too small may result in excessive filtration, leading to a loss of valuable terpenes and cannabinoids, which are essential for the flavor and potency of the rosin. Conversely, a micron size that is too large may allow too much plant material to pass through, resulting in a lower quality product that is less appealing to consumers. Therefore, the 160 micron size effectively captures the right balance, filtering out larger particles while still permitting a generous yield of high-quality oil.

Moreover, the durability of the 160 micron nylon screen press bag enhances its appeal. Constructed from high-quality materials, these bags are designed to withstand the pressures of the extraction process without tearing or degrading. This durability not only ensures a consistent extraction experience but also contributes to the longevity of the product, making it a cost-effective choice for those who frequently engage in rosin extraction. The robust nature of the nylon material allows for repeated use, which is particularly beneficial for commercial operations that require reliability and efficiency.

In addition to its practical benefits, the 160 micron size also offers versatility. It can be used effectively with a variety of starting materials, including both flower and hash. This adaptability makes it an excellent choice for extractors who may work with different types of cannabis products, as it can deliver consistent results across various applications. Furthermore, the 160 micron bag is suitable for both small-scale home extraction and larger commercial operations, making it a valuable tool for a wide range of users.

Another important aspect to consider is the impact of micron size on the flavor profile of the extracted rosin. The 160 micron screen allows for the retention of essential terpenes, which are responsible for the aroma and taste of the final product. By preserving these volatile compounds, extractors can produce rosin that not only boasts a higher potency but also offers a more enjoyable sensory experience. This is particularly significant in a market that increasingly values flavor and aroma, as consumers become more discerning about the products they choose.

In conclusion, the 160 micron nylon screen press bag represents an optimal choice for those involved in the rosin industry. Its ability to balance filtration efficiency with oil yield, combined with its durability and versatility, makes it a standout option for both novice and seasoned extractors. As the demand for high-quality rosin continues to grow, the importance of selecting the right micron size cannot be overstated. The 160 micron bag not only meets the practical needs of extractors but also enhances the overall quality of the final product, ensuring that it meets the expectations of an increasingly sophisticated consumer base.