Rosin Press Bag Tips – Avoid Common Mistakes & Boost Results

Proper Bag Size Selection

When it comes to maximizing the efficiency and quality of your rosin extraction process, the selection of the proper bag size is a critical factor that can significantly influence your results. Many individuals, especially those new to the rosin pressing technique, often overlook this aspect, leading to suboptimal yields and compromised quality. Understanding the importance of bag size not only enhances the extraction process but also helps in avoiding common pitfalls that can detract from the overall experience.

To begin with, it is essential to recognize that rosin press bags come in various sizes, each designed to accommodate different quantities of material. Selecting a bag that is too small can lead to overpacking, which may result in uneven pressure distribution during the pressing process. This unevenness can cause the material to break apart, leading to a lower yield and potentially introducing unwanted contaminants into the final product. Conversely, using a bag that is excessively large can lead to wasted space and inefficient extraction, as the material may not be adequately compressed to release the desired oils.

Moreover, the type of material being pressed plays a significant role in determining the appropriate bag size. For instance, if you are working with a small batch of high-quality flower, a smaller bag may be more suitable, as it allows for better compression and extraction of the essential oils. On the other hand, when dealing with larger quantities or denser materials, such as hash or kief, a larger bag may be necessary to ensure that the material is evenly distributed and adequately pressed. Therefore, it is crucial to assess the specific characteristics of the material you are using to make an informed decision regarding bag size.

In addition to considering the material type and quantity, it is also important to take into account the dimensions of your rosin press. Each press has its own specifications regarding the maximum size of the bags it can accommodate. Using a bag that exceeds these dimensions can lead to complications during the pressing process, such as difficulty in achieving proper closure or even damaging the press itself. Therefore, always refer to the manufacturer’s guidelines to ensure compatibility between the bag size and your equipment.

Furthermore, it is advisable to experiment with different bag sizes to determine which yields the best results for your specific setup. This trial-and-error approach can provide valuable insights into how various sizes affect the extraction process, allowing you to fine-tune your technique over time. Keep in mind that the goal is to strike a balance between maximizing yield and maintaining the quality of the extracted rosin. By carefully selecting the appropriate bag size, you can enhance the overall efficiency of your rosin extraction process.

In conclusion, the proper selection of rosin press bag size is a fundamental aspect that can greatly influence the outcome of your extraction efforts. By avoiding common mistakes associated with improper bag sizing, you can boost your results and achieve a higher quality product. As you continue to refine your technique, remember to consider the type and quantity of material, the specifications of your rosin press, and the potential benefits of experimentation. By doing so, you will not only enhance your understanding of the rosin extraction process but also elevate the quality of your final product.

Quality of Material

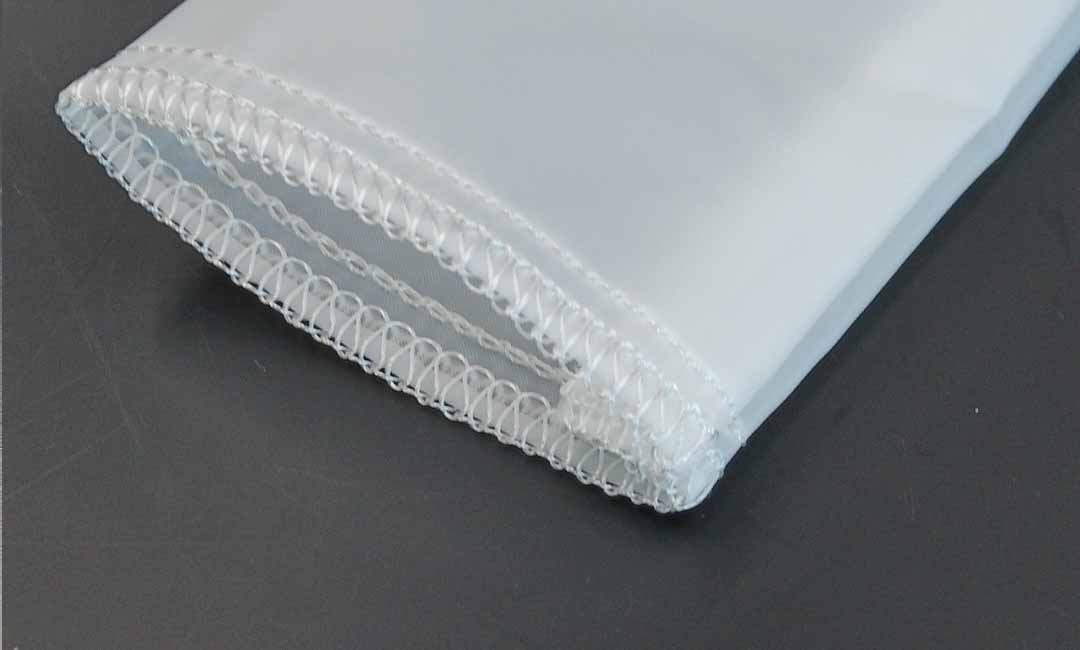

When it comes to using a rosin press, the quality of the material you use can greatly impact the results you achieve. Rosin press bags are an essential tool for extracting rosin from your favorite herbs or flowers. However, not all rosin press bags are created equal. In order to avoid common mistakes and boost your results, it is important to pay attention to the quality of the material you are using.

One of the most common mistakes people make when using rosin press bags is using low-quality material. Cheap, flimsy bags can easily tear or burst under pressure, leading to a messy and inefficient extraction process. To avoid this, it is important to invest in high-quality rosin press bags made from durable materials such as nylon or polyester.

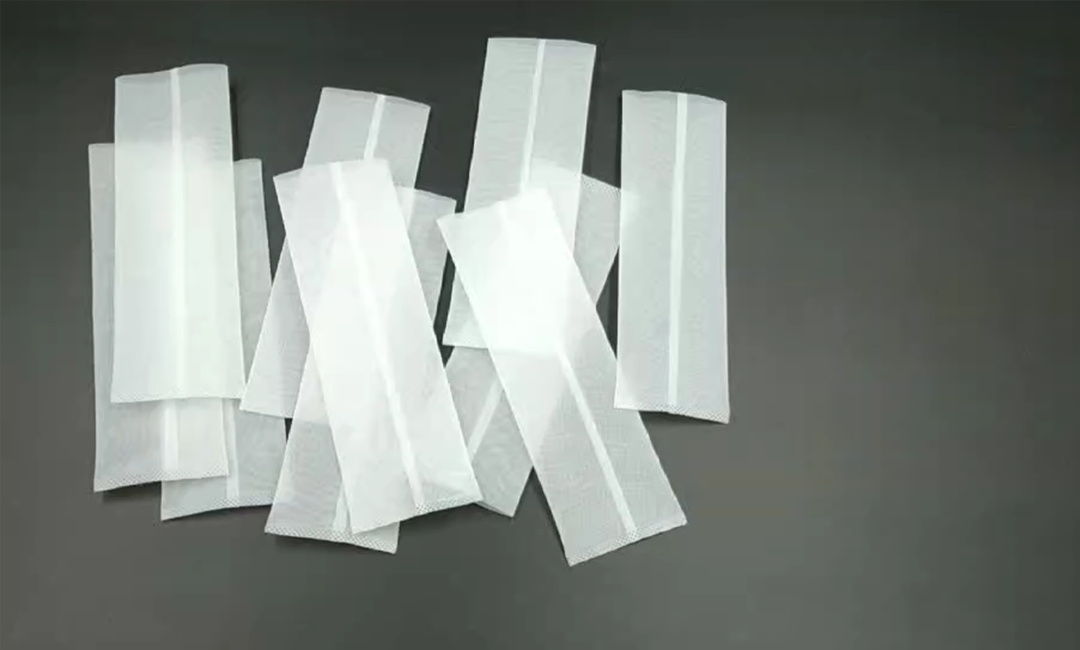

Another factor to consider when choosing rosin press bags is the micron size. The micron size of a bag refers to the size of the openings in the material, which determines the size of the particles that can pass through. Different micron sizes are suitable for different types of herbs or flowers, so it is important to choose the right size for your specific needs.

In general, finer micron sizes are ideal for extracting rosin from finer materials such as kief or bubble hash, while larger micron sizes are better suited for extracting rosin from larger, coarser materials. It is important to experiment with different micron sizes to find the one that works best for the specific material you are using.

In addition to the quality of the material and the micron size, it is also important to consider the size and shape of the rosin press bags you are using. Bags that are too small or too large for your press can lead to uneven pressure distribution and inconsistent results. It is important to choose bags that are the right size for your press and that fit snugly around the material you are extracting rosin from.

When using rosin press bags, it is important to pay attention to the temperature and pressure settings of your press. Different materials require different temperatures and pressures to achieve optimal results, so it is important to experiment with different settings to find the right combination for your specific needs.

In conclusion, the quality of the material you use in your rosin press bags can greatly impact the results you achieve. By investing in high-quality bags made from durable materials, choosing the right micron size, and paying attention to the size and shape of the bags you use, you can avoid common mistakes and boost your results. Experimenting with different temperature and pressure settings can also help you achieve optimal results. By following these tips, you can ensure that you get the most out of your rosin press and enjoy high-quality rosin extracts every time.

Packing Technique

Rosin press bags are an essential tool for extracting high-quality rosin from your favorite herbs or flowers. However, many users make common mistakes when using these bags, which can lead to subpar results. In this article, we will discuss some tips to help you avoid these mistakes and boost your rosin press results.

One of the most common mistakes that users make when using rosin press bags is overpacking them. Overpacking the bags can lead to uneven pressure distribution during the pressing process, which can result in lower yields and lower-quality rosin. To avoid this mistake, make sure to only fill the bags with the recommended amount of material, and avoid packing it too tightly.

Another common mistake that users make is using bags that are too small for the amount of material they are pressing. Using bags that are too small can lead to blowouts during the pressing process, which can result in a messy and inefficient extraction. To avoid this mistake, make sure to use bags that are the appropriate size for the amount of material you are pressing.

When packing your rosin press bags, it is important to ensure that the material is evenly distributed throughout the bag. Uneven distribution can lead to uneven pressure during the pressing process, which can result in lower yields and lower-quality rosin. To avoid this mistake, make sure to evenly distribute the material in the bag before placing it in the press.

It is also important to pay attention to the quality of the bags you are using. Low-quality bags can lead to blowouts and leaks during the pressing process, which can result in wasted material and lower yields. To avoid this mistake, make sure to invest in high-quality rosin press bags that are designed to withstand the pressure of the pressing process.

When packing your rosin press bags, it is important to pay attention to the temperature and pressure settings of your press. Using the wrong settings can lead to inefficient extractions and lower-quality rosin. To avoid this mistake, make sure to carefully follow the manufacturer’s recommendations for temperature and pressure settings, and make any necessary adjustments based on the material you are pressing.

In conclusion, using rosin press bags can help you extract high-quality rosin from your favorite herbs or flowers. However, it is important to avoid common mistakes when using these bags in order to achieve the best results. By following the tips outlined in this article, you can avoid these mistakes and boost your rosin press results.

Temperature and Pressure Control

When it comes to maximizing the efficiency and quality of your rosin extraction process, understanding the nuances of temperature and pressure control is paramount. These two factors play a critical role in determining the yield and purity of the final product, and neglecting them can lead to suboptimal results. Therefore, it is essential to approach these elements with a strategic mindset, ensuring that you avoid common pitfalls that can hinder your extraction efforts.

To begin with, temperature control is vital in the rosin extraction process. The ideal temperature range typically falls between 180°F to 220°F, depending on the material being processed. Lower temperatures tend to preserve terpenes, which are responsible for the aroma and flavor of the final product, while higher temperatures can increase yield but may also lead to the degradation of these delicate compounds. Consequently, it is crucial to experiment within this range to find the sweet spot that balances yield and quality. Moreover, using a reliable thermometer is essential for maintaining consistent temperatures throughout the process. Digital thermometers with probes can provide accurate readings, allowing for real-time adjustments as needed.

In addition to temperature, pressure control is equally important. The pressure applied during extraction can significantly influence the efficiency of the process. Generally, a pressure range of 600 to 1,200 psi is recommended for most materials. However, the optimal pressure can vary based on the specific characteristics of the material being used. For instance, denser materials may require higher pressure to achieve effective extraction, while more delicate materials may benefit from lower pressure to avoid damaging the trichomes. Therefore, it is advisable to start with a moderate pressure and gradually increase it while monitoring the results. This approach allows for fine-tuning and helps in identifying the ideal pressure for your specific setup.

Furthermore, it is essential to consider the duration of the pressing process in conjunction with temperature and pressure. The pressing time can vary based on the material and the desired outcome. Typically, pressing for 30 to 90 seconds is sufficient, but this can be adjusted based on the observed results. A longer pressing time at lower temperatures may yield a more flavorful product, while shorter pressing times at higher temperatures can increase efficiency. Therefore, keeping a detailed log of your experiments can be beneficial, as it allows you to track the effects of different combinations of temperature, pressure, and time on your yields.

Another common mistake to avoid is failing to preheat the rosin press adequately. Preheating ensures that the plates reach the desired temperature before introducing the material, which can lead to more consistent results. Additionally, it is advisable to allow the material to acclimate to the heat for a few moments before applying pressure. This practice can help in achieving a more uniform extraction and can prevent the material from being shocked by sudden temperature changes.

In conclusion, mastering temperature and pressure control is essential for anyone looking to enhance their rosin extraction results. By understanding the interplay between these factors and avoiding common mistakes, you can significantly improve both the yield and quality of your final product. Through careful experimentation and diligent monitoring, you can refine your technique, ultimately leading to a more successful and satisfying extraction experience.