Rosin Press Bag Tips for Top-Quality Extraction

Proper Bag Size Selection

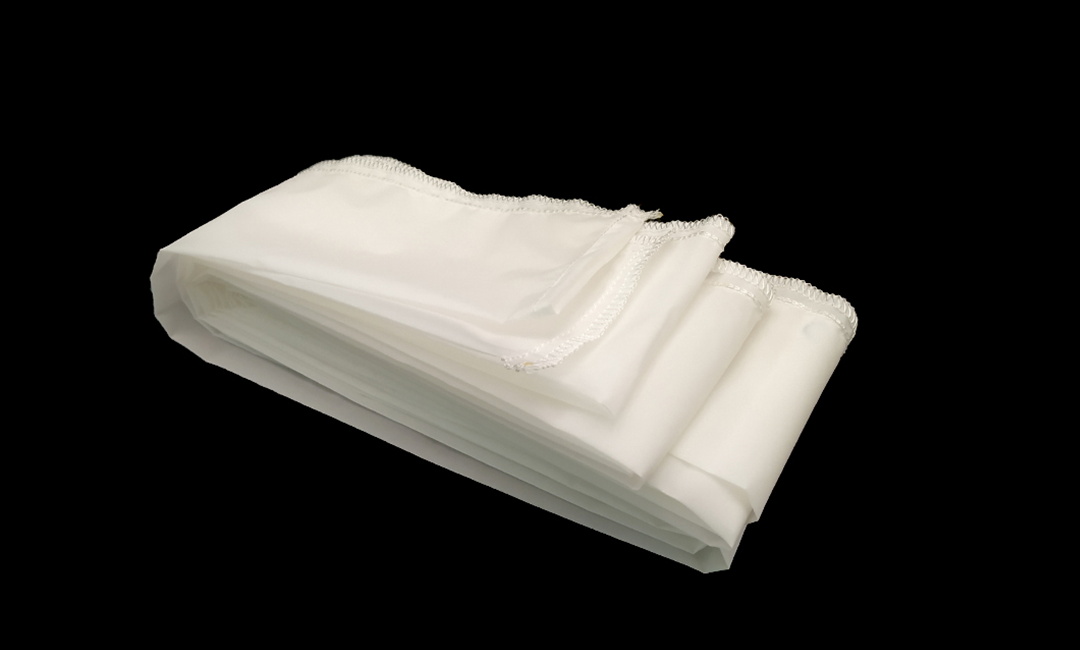

Rosin extraction has become increasingly popular among cannabis enthusiasts and home growers due to its simplicity and effectiveness in producing high-quality concentrates. One key component of the rosin extraction process is the use of rosin press bags, which help contain the material being pressed and prevent plant material from contaminating the final product. Proper bag size selection is crucial in ensuring a successful extraction process and obtaining top-quality results.

When selecting a rosin press bag, it is important to consider the size of the material being pressed. The bag should be large enough to accommodate the material without being too loose, as this can lead to blowouts and contamination of the final product. On the other hand, a bag that is too small may not allow for proper extraction and can result in lower yields.

It is recommended to use bags that are slightly larger than the material being pressed to allow for expansion during the pressing process. This will help ensure that the material is evenly distributed within the bag and prevent blowouts. Additionally, using bags with a higher micron count can help improve the quality of the final product by filtering out more impurities and plant material.

Another factor to consider when selecting a rosin press bag is the material it is made from. Bags made from high-quality materials such as nylon or polyester are more durable and less likely to break or tear during the pressing process. These materials are also heat resistant, which is important when using a rosin press at high temperatures.

In addition to size and material, the shape of the rosin press bag can also impact the extraction process. Bags that are square or rectangular in shape are ideal for pressing larger amounts of material, while round bags are better suited for smaller batches. It is important to choose a bag shape that best fits the amount of material being pressed to ensure optimal extraction results.

When using rosin press bags, it is important to properly pre-press the material before placing it in the bag. This helps to evenly distribute the material within the bag and prevent blowouts during the pressing process. It is also recommended to double-bag the material for added protection and to prevent any contamination of the final product.

In conclusion, proper bag size selection is essential in achieving top-quality extraction results when using a rosin press. By choosing the right size, material, and shape of the bag, you can ensure that the material is evenly distributed, prevent blowouts, and produce high-quality concentrates. Taking the time to select the right rosin press bag will ultimately lead to a more successful extraction process and a superior final product.

Quality of Bag Material

Rosin press bags are an essential tool for achieving top-quality extraction when using a rosin press machine. The quality of the bag material plays a crucial role in determining the overall success of the extraction process. In this article, we will discuss some tips for selecting the best rosin press bags to ensure optimal results.

When it comes to the quality of rosin press bags, there are a few key factors to consider. The first and most important factor is the material used to make the bags. High-quality rosin press bags are typically made from food-grade nylon or polyester mesh. These materials are durable, heat-resistant, and non-reactive, making them ideal for use in rosin extraction.

It is important to avoid using low-quality or cheaply made rosin press bags, as they may not be able to withstand the high temperatures and pressures generated by the rosin press machine. Inferior bags can easily tear or burst during the extraction process, leading to contamination of the final product and a loss of valuable extract.

Another important consideration when selecting rosin press bags is the micron size. The micron size refers to the size of the mesh openings in the bag, which determines the level of filtration during the extraction process. Bags with smaller micron sizes provide finer filtration, resulting in a higher-quality extract with fewer impurities.

For most rosin extraction applications, a micron size of 90 or 120 is recommended. These sizes strike a good balance between filtration and yield, allowing for the extraction of high-quality rosin without sacrificing too much of the yield. However, the ideal micron size may vary depending on the specific material being extracted, so it is important to experiment with different sizes to find the best fit for your needs.

In addition to material and micron size, the size and shape of the rosin press bags can also impact the quality of the extraction. Bags that are too small may not be able to hold enough material, leading to uneven pressure distribution and subpar results. On the other hand, bags that are too large may allow the material to spread out too much, reducing the overall yield.

To ensure optimal extraction results, it is important to select rosin press bags that are the right size and shape for your specific needs. Consider the amount of material you will be extracting, as well as the size of your rosin press plates, when choosing the appropriate bag size.

In conclusion, the quality of the rosin press bags used during extraction plays a critical role in determining the overall success of the process. By selecting high-quality bags made from durable materials, choosing the right micron size, and ensuring the bags are the correct size and shape for your needs, you can achieve top-quality extraction results with your rosin press machine. Experiment with different bags and techniques to find the perfect combination for your specific extraction needs.

Packing Technique

Rosin extraction has become increasingly popular among cannabis enthusiasts due to its simplicity and effectiveness in producing high-quality concentrates. One key component of the rosin extraction process is the use of rosin press bags, which help to contain the material being pressed and prevent any plant matter from contaminating the final product. In order to achieve top-quality extraction results, it is important to pay attention to the packing technique when using rosin press bags.

When packing material into rosin press bags, it is essential to ensure that the material is evenly distributed throughout the bag. Uneven packing can lead to inconsistent extraction results, with some areas of the material being over-pressed while others are under-pressed. To avoid this issue, it is recommended to gently pack the material into the bag using a tool such as a packing stick or a spoon. By taking the time to evenly distribute the material, you can ensure that the pressure is applied uniformly across the entire surface area of the bag, resulting in a more consistent extraction.

Another important factor to consider when packing material into rosin press bags is the size of the bag itself. Choosing the right size bag for the amount of material being pressed is crucial for achieving optimal extraction results. If the bag is too small, the material may be compressed too tightly, leading to lower yields and potentially damaging the bag. On the other hand, if the bag is too large, the material may not be compressed enough, resulting in lower-quality extraction. It is recommended to use bags that are slightly larger than the amount of material being pressed, as this allows for proper expansion during the pressing process.

In addition to packing the material evenly and choosing the right size bag, it is also important to consider the type of material being used in the rosin press bags. Different materials have different heat resistance and permeability properties, which can affect the quality of the extraction. For example, nylon bags are known for their high heat resistance and durability, making them ideal for high-temperature extractions. On the other hand, polyester bags are more permeable and can allow for better terpene retention, making them a popular choice for lower-temperature extractions. By selecting the right type of material for your rosin press bags, you can ensure that you are getting the best possible extraction results.

In conclusion, achieving top-quality extraction results with rosin press bags requires attention to detail and a careful packing technique. By evenly distributing the material, choosing the right size bag, and selecting the appropriate material for the bags, you can ensure that you are getting the most out of your extraction process. Taking the time to pack your material properly will not only improve the quality of your concentrates but also help to prolong the life of your rosin press bags. With these tips in mind, you can elevate your rosin extraction game and enjoy the full potential of this popular extraction method.

Temperature and Pressure Control

Rosin press bags are essential tools for achieving top-quality extraction when using a rosin press machine. These bags are designed to hold your material securely while allowing the rosin to flow out easily during the pressing process. However, to get the best results, it is crucial to pay attention to temperature and pressure control when using rosin press bags.

One of the most important factors to consider when using rosin press bags is temperature control. The temperature at which you press your material plays a significant role in the quality and yield of your extraction. It is essential to find the right balance between heat and pressure to achieve optimal results.

When using rosin press bags, it is recommended to start with a lower temperature and gradually increase it as needed. This will help prevent burning or overheating your material, which can result in a lower-quality extraction. It is also essential to monitor the temperature throughout the pressing process to ensure consistency and avoid any fluctuations that could affect the final product.

In addition to temperature control, pressure control is another crucial aspect to consider when using rosin press bags. The amount of pressure applied during the pressing process can significantly impact the yield and quality of your extraction. It is essential to find the right balance between pressure and temperature to achieve the best results.

When using rosin press bags, it is recommended to start with a lower pressure and gradually increase it as needed. This will help prevent blowouts or leaks that can occur when too much pressure is applied. It is also essential to monitor the pressure throughout the pressing process to ensure consistency and avoid any issues that could affect the final product.

In conclusion, temperature and pressure control are essential factors to consider when using rosin press bags for top-quality extraction. By finding the right balance between heat and pressure, you can achieve optimal results and produce high-quality rosin. It is crucial to start with lower temperatures and pressures and gradually increase them as needed to prevent any issues that could affect the final product. By paying attention to these factors and monitoring them throughout the pressing process, you can ensure a successful extraction every time.