Should You Double Bag When Pressing Rosin? Benefits and Tips Explained

Benefits of Double Bagging When Pressing Rosin

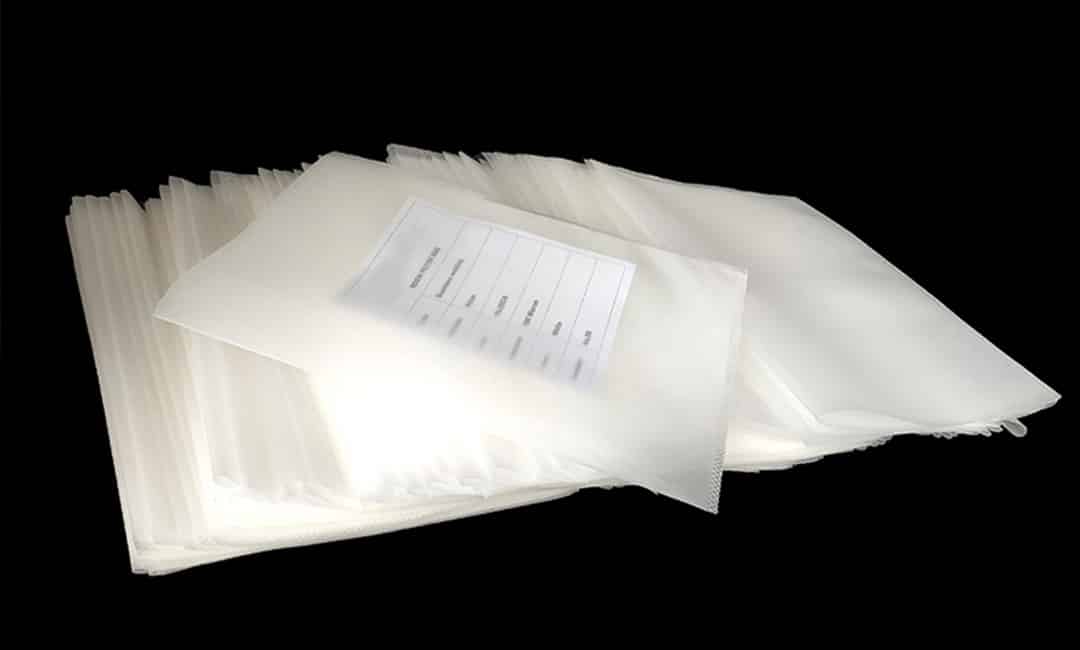

When it comes to pressing rosin, the technique employed can significantly influence the quality and yield of the final product. One method that has gained traction among enthusiasts and professionals alike is double bagging. This practice involves using two bags, typically made of micron filter material, to contain the plant material during the pressing process. The benefits of double bagging when pressing rosin are manifold, and understanding these advantages can enhance both the efficiency and quality of the extraction.

First and foremost, double bagging serves as an effective barrier against contamination. When pressing rosin, it is crucial to ensure that no unwanted particles or contaminants make their way into the final product. By using two bags, the risk of any potential leaks or tears is significantly reduced. This added layer of protection helps maintain the purity of the rosin, ensuring that the extracted oil is free from plant material and other impurities that could compromise its flavor and potency.

In addition to preventing contamination, double bagging can also improve the overall yield of rosin. When using a single bag, there is a possibility that some of the plant material may escape during the pressing process, leading to a loss of valuable oil. By employing two bags, the chances of material escaping are minimized, allowing for a more efficient extraction. This is particularly beneficial when working with high-quality flower, as maximizing yield is often a primary goal for those seeking to produce the best possible rosin.

Moreover, double bagging can enhance the quality of the rosin itself. The use of two bags allows for a more even distribution of pressure during the pressing process. This uniformity can lead to a more consistent extraction, resulting in a smoother and more refined product. Additionally, the double bagging technique can help to retain more of the terpenes and cannabinoids present in the plant material. These compounds are essential for the flavor and aroma of the rosin, and preserving them is crucial for achieving a high-quality end product.

Another significant benefit of double bagging is the ease of cleanup it provides. After pressing, the bags can be easily removed and disposed of, leaving behind minimal residue. This not only simplifies the post-pressing process but also reduces the risk of cross-contamination between different batches. For those who frequently press rosin, this streamlined cleanup can save valuable time and effort, allowing for a more efficient workflow.

Furthermore, double bagging can be particularly advantageous when working with different strains or types of material. By using separate bags for each strain, it becomes easier to maintain the unique characteristics of each product. This is especially important for those who wish to showcase the distinct flavors and effects of various strains, as it allows for a more controlled and precise extraction process.

In conclusion, the practice of double bagging when pressing rosin offers numerous benefits that can significantly enhance both the quality and efficiency of the extraction process. From preventing contamination and improving yield to facilitating easier cleanup and preserving the unique characteristics of different strains, double bagging is a technique worth considering for anyone serious about producing high-quality rosin. By understanding and implementing this method, individuals can elevate their rosin pressing endeavors to new heights, ultimately leading to a more satisfying and rewarding experience.

Tips for Effective Double Bagging Techniques

When it comes to pressing rosin, the technique of double bagging has gained popularity among enthusiasts and professionals alike. This method involves using two bags instead of one during the extraction process, and it can significantly enhance the quality and yield of the final product. To maximize the benefits of double bagging, it is essential to understand effective techniques that can streamline the process and improve results.

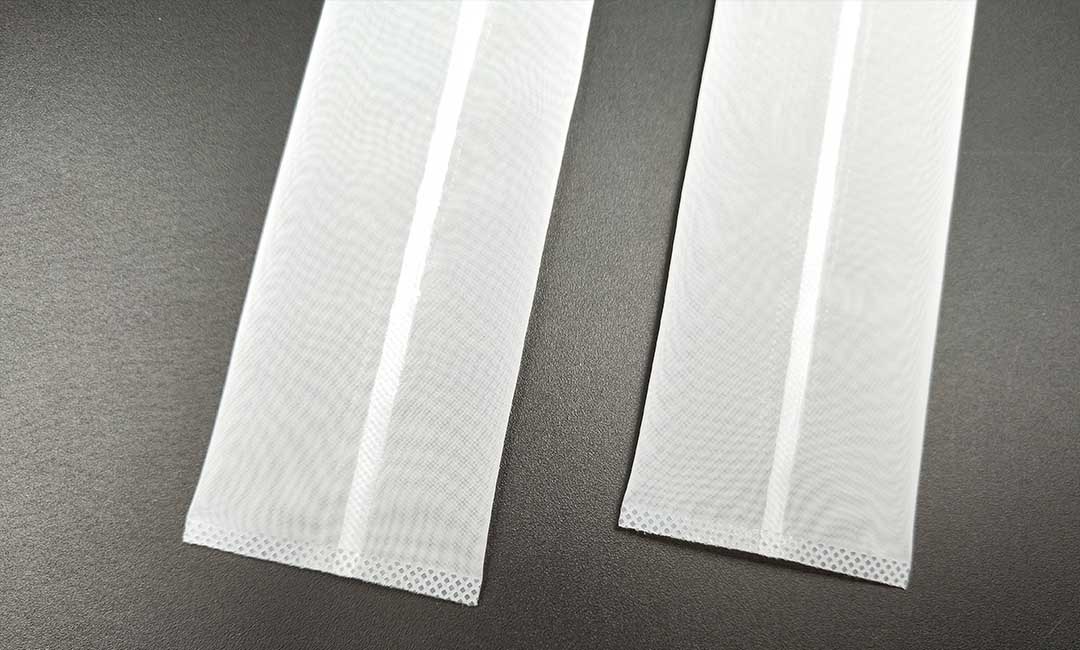

First and foremost, selecting the right bags is crucial. It is advisable to use high-quality, heat-resistant bags specifically designed for rosin extraction. These bags typically feature a micron rating that determines the size of the filter pores. A common choice is a 160-micron bag for the outer layer and a 90-micron bag for the inner layer. This combination allows for optimal filtration while preventing unwanted plant material from contaminating the rosin. Additionally, ensuring that the bags are clean and free from any residues will help maintain the purity of the extract.

Once the appropriate bags are chosen, the next step is to prepare the material for pressing. It is beneficial to break down the cannabis or hemp material into smaller pieces, as this increases the surface area and allows for more efficient extraction. Furthermore, pre-pressing the material into a compact puck can enhance the consistency of the extraction. This step not only aids in achieving a uniform pressure during the pressing process but also minimizes the risk of bag blowouts, which can occur if the material is too loosely packed.

When it comes to the actual pressing process, maintaining the right temperature and pressure is vital. It is generally recommended to start with lower temperatures, around 180 to 200 degrees Fahrenheit, and gradually increase as needed. This approach helps preserve the terpenes and cannabinoids, resulting in a more flavorful and potent rosin. Additionally, applying consistent pressure is essential; too much pressure can lead to bag rupture, while too little may result in suboptimal extraction. A hydraulic press or a rosin press with adjustable pressure settings can be particularly useful in achieving the desired results.

Moreover, timing plays a significant role in the extraction process. It is advisable to monitor the pressing duration closely, as pressing for too long can degrade the quality of the rosin. A typical pressing time ranges from 30 seconds to a few minutes, depending on the material and desired outcome. Observing the rosin as it begins to ooze out of the bags can provide valuable insight into when to stop the process. This visual cue is often a reliable indicator that the extraction is complete.

After pressing, it is important to handle the bags with care. Allowing the bags to cool slightly before opening them can prevent any residual heat from affecting the quality of the rosin. Additionally, using a clean tool to collect the rosin from the bags will help avoid contamination. Finally, proper storage of the extracted rosin is essential for preserving its quality. Storing it in a cool, dark place in an airtight container will help maintain its potency and flavor over time.

In conclusion, effective double bagging techniques can significantly enhance the rosin extraction process. By selecting the right bags, preparing the material properly, maintaining optimal temperature and pressure, and handling the final product with care, one can achieve superior results. As with any technique, practice and experimentation will lead to improved outcomes, allowing for a more rewarding rosin pressing experience.

Common Mistakes to Avoid When Double Bagging Rosin

When it comes to pressing rosin, many enthusiasts and professionals alike often consider the technique of double bagging as a means to enhance their extraction process. However, while double bagging can offer certain advantages, it is essential to be aware of common mistakes that can undermine the effectiveness of this method. Understanding these pitfalls can help ensure a more successful rosin pressing experience.

One of the most prevalent mistakes is using bags that are not specifically designed for rosin extraction. Many individuals may opt for generic bags, believing that any material will suffice. However, rosin bags are crafted from specialized materials that can withstand high temperatures and pressures without compromising the quality of the extract. Using inappropriate bags can lead to tearing or leaking, which not only diminishes yield but can also contaminate the final product with unwanted fibers or residues.

Another common error is failing to properly prepare the material before pressing. It is crucial to ensure that the plant material is adequately dried and cured, as moisture content can significantly affect the quality of the rosin. Excess moisture can lead to a lower yield and a less desirable flavor profile. Additionally, not breaking down the material into smaller pieces can hinder the extraction process. Larger chunks may not allow for even pressure distribution, resulting in uneven extraction and wasted product.

Moreover, many individuals overlook the importance of temperature control during the pressing process. While double bagging can help protect the material, it is still vital to monitor the temperature closely. Pressing at excessively high temperatures can degrade the terpenes and cannabinoids, leading to a loss of flavor and potency. Conversely, pressing at too low a temperature may not yield sufficient rosin. Therefore, finding the right balance is essential, and using a reliable temperature gauge can help avoid this common mistake.

In addition to temperature, timing is another critical factor that is often mismanaged. Some individuals may press for too long, resulting in over-extraction, which can lead to a bitter taste and undesirable consistency. On the other hand, pressing for too short a duration may not extract enough rosin, leaving behind valuable compounds. It is advisable to experiment with different pressing times to determine the optimal duration for the specific material being used.

Furthermore, neglecting to clean the bags after each use is a mistake that can have lasting repercussions. Residual plant material can accumulate in the bags, leading to contamination in future extractions. Regularly cleaning the bags not only ensures a purer product but also prolongs the lifespan of the bags themselves. Following the manufacturer’s instructions for cleaning and maintenance can help avoid this issue.

Lastly, many individuals fail to consider the importance of proper storage of the rosin after extraction. Once the rosin is collected, it should be stored in a cool, dark place to preserve its quality. Exposure to light and heat can degrade the cannabinoids and terpenes, diminishing the overall experience. Using airtight containers can further protect the rosin from environmental factors that may compromise its integrity.

In conclusion, while double bagging can enhance the rosin pressing process, it is crucial to avoid these common mistakes to achieve the best results. By using the right materials, preparing the plant properly, controlling temperature and timing, maintaining cleanliness, and storing the final product correctly, individuals can maximize their rosin yield and quality, ultimately leading to a more satisfying experience.

Comparing Single vs. Double Bagging for Rosin Quality

When it comes to pressing rosin, the choice between single and double bagging is a topic of considerable debate among enthusiasts and professionals alike. Understanding the nuances of each method can significantly impact the quality of the final product, making it essential to explore the benefits and drawbacks of both approaches.

Single bagging involves using a single micron bag to contain the plant material during the pressing process. This method is often favored for its simplicity and ease of use. By utilizing a single bag, the process becomes more straightforward, allowing for quicker setup and less material handling. Additionally, single bagging can yield a cleaner rosin, as there is less chance of cross-contamination from multiple bags. However, while single bagging may be efficient, it does come with its own set of challenges. The primary concern is that a single bag may not adequately filter out all unwanted plant material, such as fine particles and contaminants. This can lead to a less pure product, which may affect both flavor and potency.

On the other hand, double bagging involves using two bags, typically with one bag inside another, to create an additional layer of filtration. This method is often recommended for those seeking to maximize the purity and quality of their rosin. By employing a double bagging technique, the likelihood of unwanted plant material making its way into the final product is significantly reduced. The outer bag serves as an additional barrier, capturing any particles that may escape the inner bag during the pressing process. As a result, double bagging can produce a cleaner, more refined rosin, which is particularly important for connoisseurs who prioritize quality.

Moreover, double bagging can enhance the overall yield of rosin. When using a single bag, the pressure applied during the pressing process can sometimes cause the bag to rupture, leading to a loss of material and a decrease in yield. In contrast, double bagging provides an extra layer of protection, reducing the risk of bag failure and allowing for a more efficient extraction process. This can be particularly beneficial when working with high-quality flower or concentrates, where maximizing yield is crucial.

However, it is important to note that double bagging may require more time and effort in terms of setup and cleanup. The additional bagging process can be cumbersome, and the need to manage two bags may complicate the pressing procedure. Furthermore, some users report that double bagging can lead to a slightly lower yield per press due to the increased resistance created by the extra layer. Therefore, while the benefits of double bagging are clear, it is essential to weigh these against the potential drawbacks.

In conclusion, the decision to single or double bag when pressing rosin ultimately depends on the individual’s priorities and preferences. For those who value simplicity and speed, single bagging may be the preferred choice. Conversely, for those who prioritize purity and yield, double bagging offers significant advantages. By carefully considering the specific goals of the rosin pressing process, users can make an informed decision that aligns with their desired outcomes, ensuring a high-quality product that meets their expectations.