The Future of Filtration: High Flow Pleated Filters in Focus

Advancements in High Flow Pleated Filter Technology

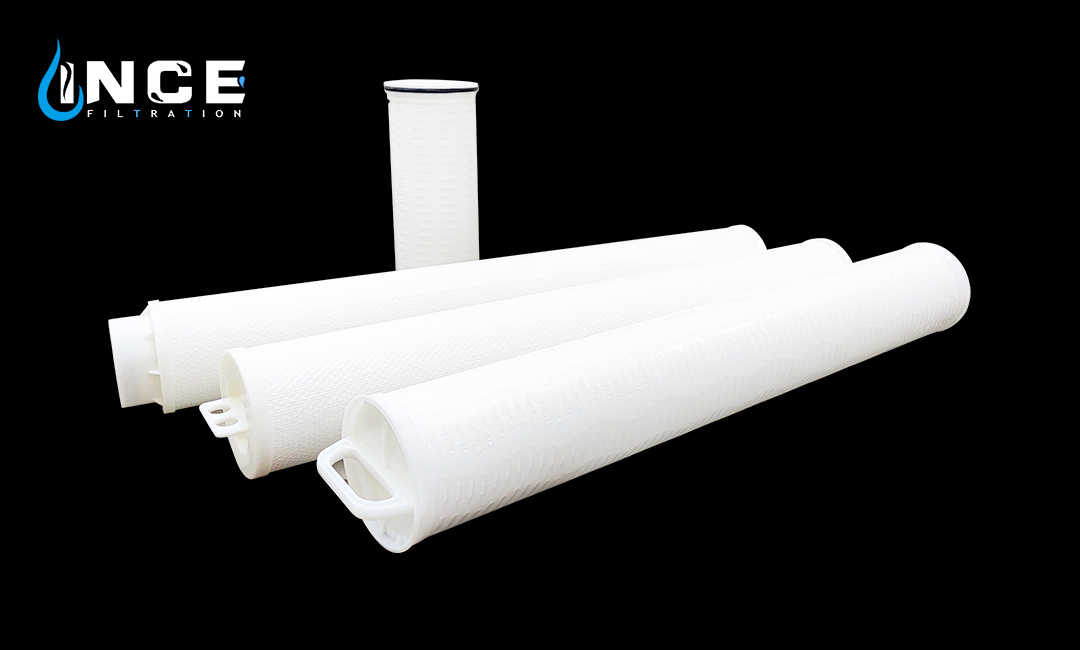

Filtration technology has come a long way in recent years, with advancements in high flow pleated filters leading the charge. These filters are designed to handle high flow rates while maintaining efficiency and effectiveness in removing contaminants from liquids and gases. As industries continue to demand higher performance from their filtration systems, high flow pleated filters are becoming an increasingly popular choice.

One of the key benefits of high flow pleated filters is their ability to handle a larger volume of fluid without sacrificing filtration quality. Traditional filters may struggle to maintain efficiency at high flow rates, leading to increased pressure drop and reduced filter life. High flow pleated filters, on the other hand, are specifically designed to handle these challenges, with a larger surface area and greater dirt-holding capacity to ensure consistent performance even under high flow conditions.

Another advantage of high flow pleated filters is their versatility. These filters can be used in a wide range of applications, from industrial processes to water treatment systems. Whether filtering water, chemicals, or air, high flow pleated filters can provide the high level of filtration efficiency required to meet industry standards and regulations. This versatility makes them a cost-effective solution for businesses looking to streamline their filtration processes and improve overall system performance.

In addition to their efficiency and versatility, high flow pleated filters are also known for their durability. Made from high-quality materials such as polypropylene, polyester, or fiberglass, these filters are designed to withstand harsh operating conditions and maintain their performance over time. This durability not only extends the life of the filter but also reduces maintenance costs and downtime, making high flow pleated filters a reliable choice for businesses looking to optimize their filtration systems.

As technology continues to evolve, so too do high flow pleated filters. Manufacturers are constantly innovating to improve the performance and efficiency of these filters, with advancements in materials, design, and manufacturing processes driving the development of next-generation filtration solutions. From enhanced dirt-holding capacity to improved flow rates, these advancements are helping businesses achieve higher levels of filtration performance than ever before.

Looking to the future, high flow pleated filters are poised to play a key role in the evolution of filtration technology. With their ability to handle high flow rates, maintain efficiency, and withstand harsh operating conditions, these filters are well-suited to meet the demands of industries seeking to improve their filtration processes. As businesses continue to prioritize efficiency, performance, and sustainability, high flow pleated filters will be a critical component in achieving these goals.

In conclusion, high flow pleated filters represent the future of filtration technology. With their efficiency, versatility, and durability, these filters are well-equipped to meet the evolving needs of industries seeking high-performance filtration solutions. As advancements in technology continue to drive innovation in the field of filtration, high flow pleated filters will remain at the forefront, providing businesses with the tools they need to optimize their filtration processes and achieve higher levels of performance than ever before.

Applications of High Flow Pleated Filters in Various Industries

High flow pleated filters are increasingly becoming essential components across various industries due to their superior filtration capabilities and efficiency. These filters, characterized by their large surface area and pleated design, allow for higher flow rates while maintaining effective particle removal. As industries strive for improved operational efficiency and compliance with stringent environmental regulations, the adoption of high flow pleated filters is gaining momentum.

In the water treatment sector, high flow pleated filters play a pivotal role in ensuring the purity and safety of drinking water. Their ability to handle large volumes of water while effectively removing contaminants makes them ideal for municipal water treatment facilities. These filters can efficiently capture sediments, bacteria, and other impurities, thereby enhancing the overall quality of the water supply. Furthermore, their longevity and reduced maintenance requirements contribute to lower operational costs, making them a preferred choice for water treatment professionals.

Similarly, in the food and beverage industry, high flow pleated filters are crucial for maintaining product quality and safety. These filters are employed in various applications, including the filtration of juices, wines, and dairy products. By removing unwanted particles and microorganisms, they help ensure that the final products meet health standards and consumer expectations. The ability of these filters to operate at high flow rates without compromising filtration efficiency is particularly beneficial in high-volume production environments, where time and quality are of the essence.

The pharmaceutical industry also benefits significantly from the use of high flow pleated filters. In this sector, the need for sterile and contaminant-free environments is paramount. High flow pleated filters are utilized in the filtration of raw materials, as well as in the final stages of drug production. Their effectiveness in removing particulates and microorganisms ensures that pharmaceutical products are safe for consumption. Additionally, the filters’ ability to handle large volumes of liquids without clogging is essential in maintaining the efficiency of production processes.

In the industrial sector, high flow pleated filters are employed in various applications, including coolant filtration and process water treatment. These filters help maintain the cleanliness of machinery and equipment, thereby extending their lifespan and reducing downtime. By effectively removing contaminants from coolants and process waters, high flow pleated filters contribute to improved operational efficiency and reduced maintenance costs. Industries such as metalworking and manufacturing have recognized the value of these filters in enhancing productivity and ensuring compliance with environmental regulations.

Moreover, the energy sector is increasingly adopting high flow pleated filters for applications such as oil and gas filtration. In these industries, the need for reliable filtration solutions is critical to prevent equipment failure and ensure the safety of operations. High flow pleated filters can effectively remove particulates from fuels and lubricants, thereby enhancing the performance and reliability of machinery. Their robust design and high dirt-holding capacity make them suitable for the demanding conditions often encountered in energy production.

In conclusion, the applications of high flow pleated filters span a wide range of industries, each benefiting from their unique advantages. As industries continue to prioritize efficiency, safety, and compliance, the demand for these advanced filtration solutions is expected to grow. The ability of high flow pleated filters to deliver superior performance while reducing operational costs positions them as a vital component in the future of filtration technology. As innovations continue to emerge, these filters will undoubtedly play a crucial role in shaping the landscape of industrial filtration.

Environmental Impact of High Flow Pleated Filters

High flow pleated filters are becoming increasingly popular in various industries due to their efficiency and effectiveness in removing contaminants from liquids and gases. However, as with any filtration system, there are environmental considerations that must be taken into account when using high flow pleated filters.

One of the primary environmental impacts of high flow pleated filters is the disposal of used filters. These filters can accumulate a significant amount of contaminants over time, which can pose a risk to the environment if not disposed of properly. It is important for industries to have a proper disposal plan in place to ensure that used filters are handled in a way that minimizes their impact on the environment.

Another environmental consideration when using high flow pleated filters is the energy consumption required to operate them. These filters typically require a pump or other mechanism to push the liquid or gas through the filter media, which can consume a significant amount of energy. Industries should consider the energy efficiency of their filtration systems and look for ways to reduce energy consumption where possible.

In addition to energy consumption, the materials used in high flow pleated filters can also have an impact on the environment. Some filters are made from materials that are not biodegradable or recyclable, which can contribute to waste accumulation in landfills. Industries should look for filters that are made from environmentally friendly materials and can be recycled or disposed of in a sustainable manner.

Despite these environmental considerations, high flow pleated filters offer several benefits that can help mitigate their impact on the environment. For example, these filters are highly efficient at removing contaminants, which can help industries comply with environmental regulations and reduce their overall environmental footprint. By using high flow pleated filters, industries can ensure that their processes are as clean and sustainable as possible.

Furthermore, high flow pleated filters can help industries reduce their water and energy consumption, which can have a positive impact on the environment. By removing contaminants from liquids and gases more efficiently, these filters can help industries conserve resources and reduce their overall environmental impact. This can lead to cost savings for industries as well as a reduced impact on the environment.

Overall, the environmental impact of high flow pleated filters is a complex issue that requires careful consideration by industries. While these filters offer many benefits in terms of efficiency and effectiveness, it is important for industries to be mindful of their environmental impact and take steps to minimize it. By using environmentally friendly materials, reducing energy consumption, and properly disposing of used filters, industries can ensure that high flow pleated filters are a sustainable solution for their filtration needs.

Comparing High Flow Pleated Filters to Traditional Filtration Methods

Filtration is a critical process in many industries, from water treatment to pharmaceutical manufacturing. Traditional filtration methods have long been relied upon to remove impurities and particles from liquids and gases. However, as technology advances, new and more efficient filtration methods are being developed. One such innovation is the high flow pleated filter.

High flow pleated filters are designed to handle a higher flow rate than traditional filters, making them ideal for applications where large volumes of liquid or gas need to be filtered quickly and efficiently. These filters are made up of pleated media that provides a larger surface area for filtration, allowing for greater flow rates without sacrificing filtration efficiency.

One of the key advantages of high flow pleated filters is their ability to reduce the number of filters needed in a system. Because these filters can handle a higher flow rate, fewer filters are required to achieve the same level of filtration as traditional methods. This not only saves on space and installation costs but also reduces maintenance and replacement costs over time.

In addition to their efficiency, high flow pleated filters also offer improved performance in terms of particle removal. The pleated media used in these filters is designed to capture a wide range of particle sizes, from large contaminants to submicron particles. This ensures that the filtered liquid or gas meets the required purity standards, making high flow pleated filters suitable for a variety of applications, including food and beverage processing, pharmaceutical manufacturing, and water treatment.

Compared to traditional filtration methods, high flow pleated filters offer a number of benefits. Traditional filters typically have a lower flow rate and require more frequent replacement due to clogging. High flow pleated filters, on the other hand, can handle a higher flow rate and are less prone to clogging, resulting in longer filter life and reduced maintenance costs.

Another advantage of high flow pleated filters is their ease of installation. These filters are designed to be easily integrated into existing filtration systems, making them a cost-effective upgrade for companies looking to improve their filtration processes. With their high flow rates and superior particle removal capabilities, high flow pleated filters are a versatile and efficient solution for a wide range of industries.

In conclusion, high flow pleated filters represent the future of filtration technology. With their high flow rates, superior particle removal capabilities, and cost-effective design, these filters offer a number of advantages over traditional filtration methods. As industries continue to demand higher levels of filtration efficiency, high flow pleated filters are likely to become the standard choice for many applications. Whether you are looking to improve the performance of your filtration system or simply reduce maintenance costs, high flow pleated filters are a reliable and effective solution.