The Ideal Micron Bag Size for Pressing Flower Rosin

Understanding the Importance of Micron Bag Size

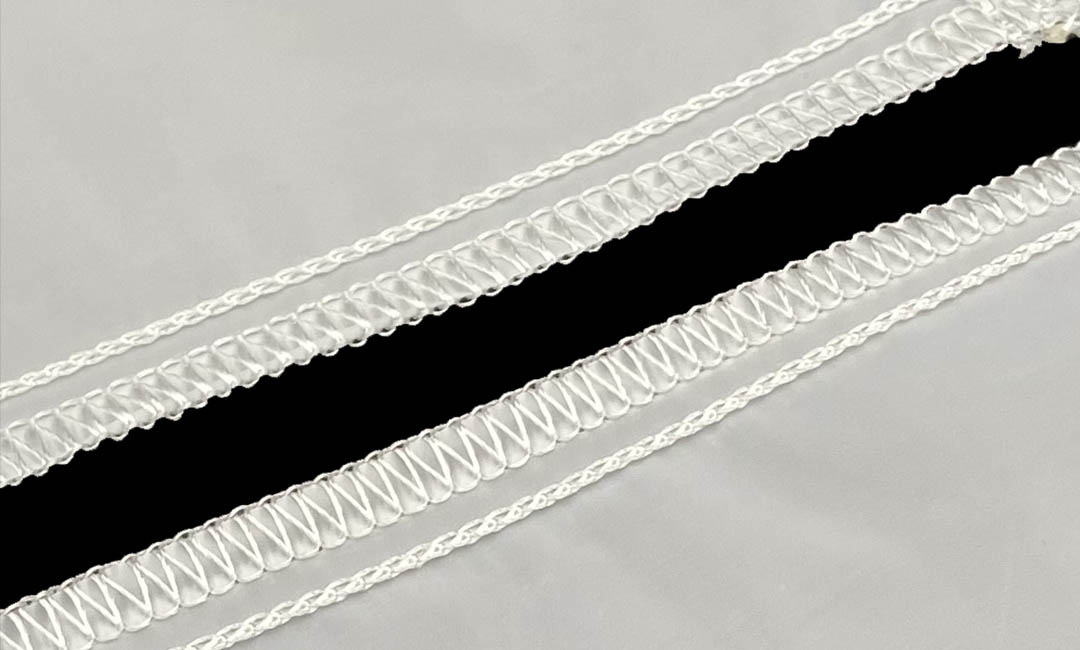

When it comes to pressing flower rosin, the micron bag size plays a crucial role in determining the quality and yield of the final product. The ideal micron bag size ensures that the right amount of pressure is applied to extract the desired compounds from the flower material while minimizing the risk of contamination.

Choosing the correct micron bag size can significantly impact the efficiency of the pressing process. A bag that is too small may restrict the flow of rosin, leading to lower yields, while a bag that is too large may allow unwanted plant material to contaminate the extract. Therefore, understanding the importance of micron bag size is essential for achieving optimal results.

Benefits of Using the Ideal Micron Bag Size

Utilizing the ideal micron bag size for pressing flower rosin offers a myriad of benefits for both producers and consumers. Firstly, the right bag size ensures maximum extraction of cannabinoids and terpenes, resulting in a more potent and flavorful rosin product.

Moreover, by using the correct micron bag size, producers can minimize waste and maximize their yield, ultimately improving their overall profitability. Consumers also benefit from higher-quality rosin that retains the full spectrum of compounds present in the original flower material, enhancing their experience and satisfaction.

How to Choose the Perfect Micron Bag Size

When selecting the perfect micron bag size for pressing flower rosin, it is essential to consider the specific characteristics of the material being processed. Different strains and textures may require varying micron sizes to achieve optimal results.

Additionally, factors such as desired yield, potency, and flavor profile should also be taken into account when choosing the bag size. Conducting small-scale experiments with different micron sizes can help determine the most suitable option for each unique batch of flower material, ensuring consistent quality and performance.