The Role of 5-Micron Pleated Filters in Pre-Filtration Systems

Benefits of Using 5-Micron Pleated Filters in Pre-Filtration Systems

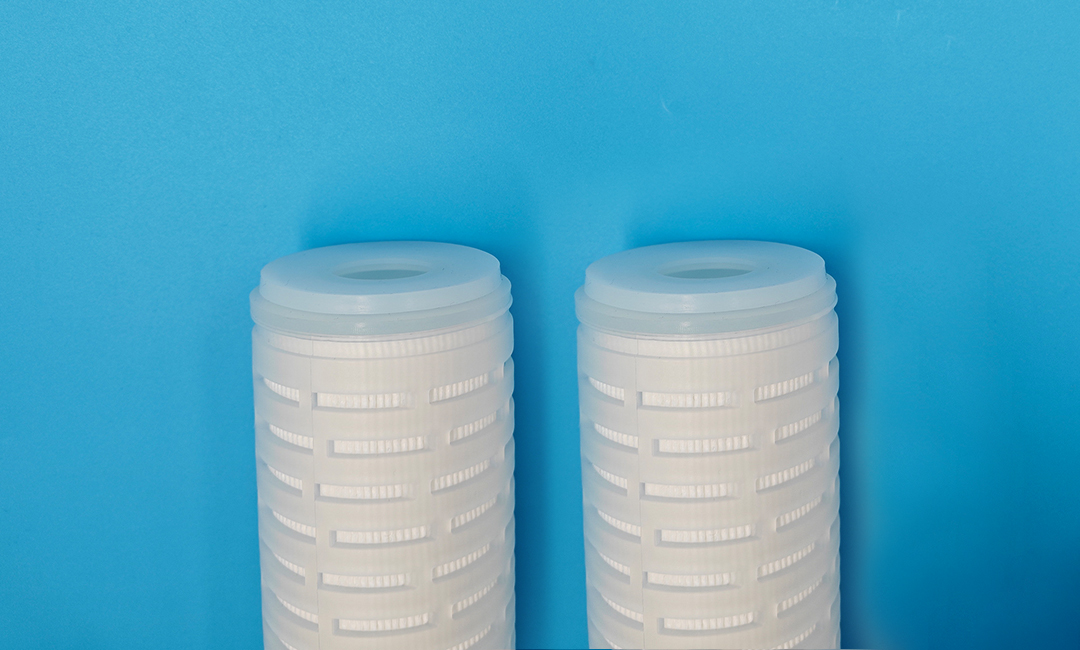

Pre-filtration systems play a crucial role in maintaining the efficiency and longevity of downstream filtration equipment. One key component of pre-filtration systems is the 5-micron pleated filter. These filters are designed to capture particles as small as 5 microns in size, providing an effective barrier against contaminants that can damage or clog more sensitive filtration components.

One of the primary benefits of using 5-micron pleated filters in pre-filtration systems is their ability to remove a wide range of contaminants from the water supply. These filters are capable of capturing particles such as sediment, rust, sand, and silt, as well as larger microorganisms like cysts and protozoa. By removing these contaminants before they reach the main filtration system, 5-micron pleated filters help to prevent damage and reduce the frequency of maintenance and replacement of more expensive filtration components.

In addition to their superior filtration capabilities, 5-micron pleated filters are also highly durable and long-lasting. Made from high-quality materials such as polypropylene or polyester, these filters are designed to withstand high flow rates and pressures without compromising their filtration efficiency. This durability not only extends the lifespan of the filter itself but also helps to protect downstream filtration equipment from damage caused by excessive pressure or flow rates.

Another advantage of using 5-micron pleated filters in pre-filtration systems is their ease of installation and maintenance. These filters are typically designed to be compatible with a wide range of filtration systems, making them easy to integrate into existing setups. Additionally, most 5-micron pleated filters are disposable, meaning that they can be easily replaced when they become clogged or reach the end of their lifespan. This simplicity of maintenance helps to minimize downtime and ensure that the pre-filtration system continues to operate at peak efficiency.

Furthermore, 5-micron pleated filters are cost-effective solutions for pre-filtration applications. Compared to more complex filtration technologies, such as reverse osmosis or UV sterilization, pleated filters are relatively inexpensive to purchase and maintain. This affordability makes them an attractive option for businesses and homeowners looking to improve the quality of their water supply without breaking the bank.

In conclusion, 5-micron pleated filters play a vital role in pre-filtration systems by providing effective and efficient filtration of contaminants in the water supply. Their superior filtration capabilities, durability, ease of installation and maintenance, and cost-effectiveness make them an ideal choice for a wide range of applications. By incorporating 5-micron pleated filters into pre-filtration systems, users can ensure the longevity and efficiency of downstream filtration equipment while enjoying clean and safe water for drinking, cooking, and other household or industrial uses.

Importance of Proper Maintenance and Replacement of 5-Micron Pleated Filters

Proper maintenance and replacement of 5-micron pleated filters are crucial in ensuring the effectiveness of pre-filtration systems. These filters play a vital role in removing contaminants and particles from water, air, or other fluids before they enter the main filtration system. By capturing larger particles and debris, 5-micron pleated filters help extend the life of more expensive filters downstream, ultimately saving time and money in the long run.

One of the key reasons why regular maintenance and replacement of 5-micron pleated filters are essential is to prevent clogging. Over time, these filters can become clogged with dirt, debris, and other contaminants, reducing their efficiency and restricting the flow of fluid through the system. This can lead to decreased performance of the entire filtration system and potentially cause damage to equipment or machinery.

To avoid these issues, it is important to follow the manufacturer’s recommendations for filter replacement intervals and regularly inspect the filters for signs of clogging or damage. By replacing 5-micron pleated filters on a regular basis, you can ensure that your pre-filtration system continues to operate at peak efficiency and effectively remove contaminants from the fluid being filtered.

In addition to preventing clogging, proper maintenance and replacement of 5-micron pleated filters also help to maintain water quality. These filters are designed to remove a wide range of contaminants, including sediment, rust, sand, and other particles that can affect the taste, odor, and appearance of water. By replacing the filters as recommended, you can ensure that your water remains clean, clear, and safe for consumption.

Furthermore, regular maintenance and replacement of 5-micron pleated filters can also help to protect downstream equipment and machinery. By capturing larger particles and debris before they reach more sensitive components, these filters help prevent damage and extend the life of expensive equipment. This can result in fewer repairs, reduced downtime, and lower maintenance costs over time.

It is important to note that the frequency of filter replacement will depend on several factors, including the quality of the water or fluid being filtered, the flow rate through the system, and the level of contaminants present. In some cases, filters may need to be replaced more frequently to maintain optimal performance. It is important to monitor the condition of the filters regularly and replace them as needed to ensure the continued effectiveness of the pre-filtration system.

In conclusion, proper maintenance and replacement of 5-micron pleated filters are essential for the efficient operation of pre-filtration systems. By following the manufacturer’s recommendations and regularly inspecting and replacing the filters, you can prevent clogging, maintain water quality, and protect downstream equipment. Investing in the proper care of these filters will ultimately save time and money in the long run, while ensuring that your filtration system continues to operate at peak performance.

Comparison of 5-Micron Pleated Filters with Other Types of Pre-Filtration Systems

Pre-filtration systems play a crucial role in maintaining the efficiency and longevity of downstream filtration processes. Among the various types of pre-filtration systems available, 5-micron pleated filters are widely used for their effectiveness in capturing particles and contaminants before they reach the main filtration system. In this article, we will explore the role of 5-micron pleated filters in pre-filtration systems and compare them with other types of pre-filtration systems.

5-micron pleated filters are designed to capture particles as small as 5 microns in size, making them ideal for removing fine particles and contaminants from liquids and gases. The pleated design of these filters provides a large surface area for filtration, allowing for greater particle retention and longer filter life. Compared to other types of pre-filtration systems, such as depth filters and bag filters, 5-micron pleated filters offer superior filtration efficiency and performance.

One of the key advantages of 5-micron pleated filters is their ability to remove a wide range of contaminants, including dirt, rust, sand, and other particulate matter. The tight pore size of these filters ensures that even the smallest particles are captured, preventing them from clogging downstream filtration systems and causing damage to equipment. In contrast, depth filters and bag filters may not be as effective in capturing fine particles, leading to reduced filtration efficiency and increased maintenance costs.

Another benefit of 5-micron pleated filters is their high flow rates, which allow for faster filtration and increased productivity. The pleated design of these filters minimizes pressure drop, ensuring a steady flow of liquid or gas through the filtration system. This is especially important in industrial applications where high flow rates are required to maintain production efficiency. In comparison, depth filters and bag filters may have lower flow rates due to their design, resulting in slower filtration and potential bottlenecks in the process.

In terms of maintenance, 5-micron pleated filters are easy to replace and require minimal downtime for filter changes. The pleated design allows for quick and simple installation, reducing the time and labor required for maintenance. Additionally, the durable construction of these filters ensures long-lasting performance, reducing the frequency of filter replacements and overall operating costs. Depth filters and bag filters, on the other hand, may be more difficult to replace and require more frequent maintenance, leading to increased downtime and higher maintenance expenses.

Overall, 5-micron pleated filters offer superior filtration efficiency, high flow rates, and easy maintenance compared to other types of pre-filtration systems. Their ability to capture fine particles and contaminants makes them an essential component of pre-filtration systems in a wide range of industries, including water treatment, food and beverage, pharmaceuticals, and manufacturing. By choosing 5-micron pleated filters for pre-filtration applications, businesses can ensure the reliability and performance of their filtration systems while reducing operating costs and downtime.