The Role of Polyester Conveyor Belt Fabric in Modern Industries

Advantages of Polyester Conveyor Belt Fabric in Manufacturing Processes

Polyester conveyor belt fabric has emerged as a pivotal component in modern manufacturing processes, offering a range of advantages that enhance operational efficiency and product quality. One of the primary benefits of polyester fabric is its exceptional strength-to-weight ratio. This characteristic allows for the construction of lightweight conveyor systems that do not compromise on durability. As a result, manufacturers can transport materials over long distances without the added burden of heavy equipment, thereby reducing energy consumption and operational costs.

In addition to its strength, polyester conveyor belt fabric exhibits remarkable resistance to abrasion and wear. This durability is particularly advantageous in industries where materials are subjected to harsh conditions, such as mining, construction, and recycling. The ability of polyester to withstand friction and impact ensures that the conveyor belts maintain their integrity over time, minimizing the need for frequent replacements. Consequently, manufacturers can enjoy reduced downtime and maintenance costs, which ultimately contributes to increased productivity.

Moreover, polyester conveyor belts are known for their excellent dimensional stability. This property is crucial in manufacturing processes where precision is paramount. The ability of polyester to maintain its shape and size under varying temperatures and loads ensures that products are transported consistently and accurately. This stability not only enhances the efficiency of the production line but also reduces the risk of product damage, thereby improving overall quality control.

Another significant advantage of polyester conveyor belt fabric is its resistance to moisture and chemicals. In many manufacturing environments, exposure to water, oils, and various chemicals is inevitable. Polyester’s inherent resistance to these substances means that the conveyor belts can operate effectively without degrading or losing their structural integrity. This resilience is particularly beneficial in industries such as food processing and pharmaceuticals, where hygiene and safety are critical. By utilizing polyester conveyor belts, manufacturers can ensure compliance with industry standards while maintaining the quality of their products.

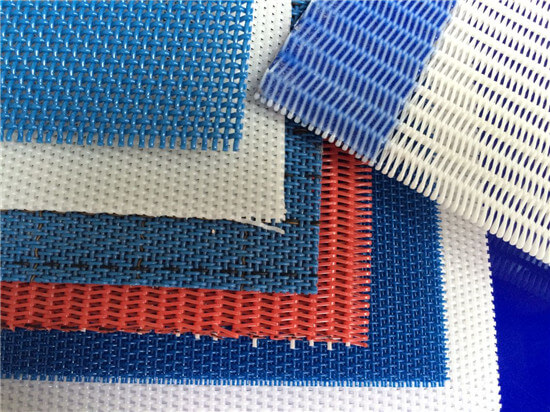

Furthermore, the versatility of polyester conveyor belt fabric allows for customization to meet specific operational needs. Manufacturers can choose from a variety of belt designs, thicknesses, and surface textures to optimize performance for different applications. This adaptability not only enhances the efficiency of material handling but also allows for the seamless integration of conveyor systems into existing production lines. As a result, businesses can tailor their manufacturing processes to achieve maximum efficiency and effectiveness.

In addition to these practical advantages, polyester conveyor belts also contribute to sustainability efforts within the manufacturing sector. The lightweight nature of polyester reduces energy consumption during operation, which aligns with the growing emphasis on environmentally friendly practices. Furthermore, many manufacturers are now producing polyester conveyor belts from recycled materials, thereby minimizing waste and promoting a circular economy. This commitment to sustainability not only benefits the environment but also enhances the corporate image of businesses that prioritize eco-friendly practices.

In conclusion, the advantages of polyester conveyor belt fabric in manufacturing processes are manifold. From its strength and durability to its resistance to moisture and chemicals, polyester offers a reliable solution for various industrial applications. The ability to customize these belts further enhances their utility, allowing manufacturers to optimize their operations. As industries continue to evolve, the role of polyester conveyor belt fabric will undoubtedly remain integral to achieving efficiency, sustainability, and product quality in modern manufacturing.

The Impact of Polyester Conveyor Belts on Material Handling Efficiency

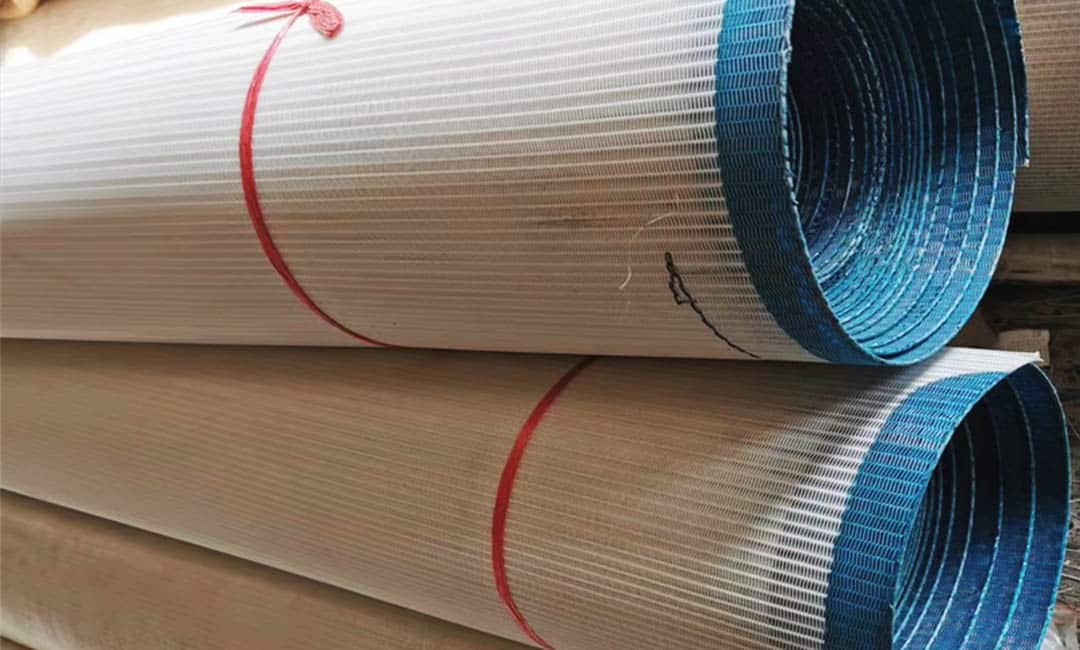

In the realm of modern industries, the efficiency of material handling systems is paramount to operational success. One of the key components that significantly influences this efficiency is the polyester conveyor belt fabric. This material has gained prominence due to its unique properties, which enhance the performance of conveyor systems across various sectors. As industries strive for increased productivity and reduced operational costs, the role of polyester conveyor belts becomes increasingly critical.

Polyester conveyor belts are renowned for their strength and durability, which are essential characteristics in material handling applications. The inherent tensile strength of polyester fibers allows these belts to withstand heavy loads and resist wear and tear over time. Consequently, industries that rely on the transportation of bulk materials, such as mining, manufacturing, and logistics, benefit from the longevity and reliability of polyester belts. This durability translates into fewer replacements and repairs, ultimately leading to lower maintenance costs and increased uptime for production lines.

Moreover, the lightweight nature of polyester conveyor belts contributes to their efficiency in material handling. Unlike heavier materials, polyester belts reduce the overall weight of the conveyor system, which can lead to lower energy consumption during operation. This energy efficiency is particularly important in industries where large volumes of materials are transported continuously. By minimizing the energy required to move the belt, companies can achieve significant cost savings while also reducing their environmental footprint. Thus, the adoption of polyester conveyor belts aligns with the growing emphasis on sustainability in industrial practices.

In addition to their physical properties, polyester conveyor belts offer versatility in design and application. They can be manufactured in various widths, lengths, and thicknesses, allowing for customization to meet specific operational needs. This adaptability makes them suitable for a wide range of materials, from lightweight packages to heavy bulk goods. Furthermore, polyester belts can be engineered with different surface textures and coatings to enhance grip and reduce slippage, thereby improving the overall efficiency of material handling processes. As a result, industries can optimize their conveyor systems to handle diverse materials effectively, ensuring smooth and uninterrupted operations.

Another significant advantage of polyester conveyor belts is their resistance to moisture and chemicals. In environments where exposure to water, oils, or other corrosive substances is common, polyester belts maintain their integrity and performance. This resistance not only prolongs the lifespan of the belts but also ensures consistent material handling efficiency, even in challenging conditions. Industries such as food processing, pharmaceuticals, and chemical manufacturing particularly benefit from this property, as it allows for safe and reliable transportation of materials without compromising hygiene or safety standards.

Furthermore, the ease of installation and maintenance associated with polyester conveyor belts cannot be overlooked. Their lightweight design simplifies the installation process, reducing downtime during setup. Additionally, routine maintenance is straightforward, allowing for quick inspections and repairs. This ease of use enhances operational efficiency, as companies can focus on their core activities without being burdened by complex maintenance procedures.

In conclusion, the impact of polyester conveyor belts on material handling efficiency is profound and multifaceted. Their strength, lightweight nature, versatility, resistance to environmental factors, and ease of maintenance collectively contribute to enhanced operational performance across various industries. As businesses continue to seek ways to improve productivity and reduce costs, the adoption of polyester conveyor belt fabric will undoubtedly play a pivotal role in shaping the future of material handling systems.

Innovations in Polyester Conveyor Belt Fabric Technology for Industrial Applications

In recent years, the industrial landscape has witnessed significant advancements in the technology surrounding polyester conveyor belt fabric, which has become a cornerstone in various sectors, including manufacturing, mining, and logistics. These innovations have not only enhanced the performance and durability of conveyor systems but have also contributed to increased efficiency and reduced operational costs. As industries continue to evolve, the demand for high-quality conveyor belts that can withstand rigorous conditions has prompted manufacturers to invest in research and development, leading to the emergence of cutting-edge polyester fabric technologies.

One of the most notable innovations in polyester conveyor belt fabric technology is the development of advanced weaving techniques. Traditional weaving methods have been enhanced to produce fabrics that exhibit superior tensile strength and flexibility. This improvement allows conveyor belts to handle heavier loads and operate at higher speeds without compromising their structural integrity. Furthermore, the introduction of specialized weaves, such as the use of multi-layered fabrics, has resulted in belts that are not only stronger but also more resistant to wear and tear. This is particularly beneficial in industries where abrasive materials are handled, as it extends the lifespan of the conveyor system and reduces the frequency of replacements.

In addition to improved weaving techniques, the incorporation of high-performance coatings has revolutionized polyester conveyor belt fabric technology. These coatings serve multiple purposes, including enhancing the belt’s resistance to chemicals, oils, and extreme temperatures. For instance, the application of polyurethane or rubber coatings can significantly increase the belt’s durability in harsh environments, making it suitable for applications in the food processing, chemical, and mining industries. Moreover, these coatings can also provide anti-static properties, which are essential in environments where static electricity could pose a risk to both equipment and personnel.

Another significant advancement is the integration of smart technology into polyester conveyor belts. The advent of IoT (Internet of Things) has enabled the development of smart conveyor systems that can monitor performance in real-time. Sensors embedded within the conveyor belts can track various parameters, such as temperature, load weight, and wear levels. This data can be analyzed to predict maintenance needs, thereby minimizing downtime and optimizing operational efficiency. By leveraging this technology, industries can transition from reactive to proactive maintenance strategies, ultimately leading to cost savings and enhanced productivity.

Moreover, sustainability has become a critical focus in the development of polyester conveyor belt fabrics. Manufacturers are increasingly exploring eco-friendly materials and production processes to reduce their environmental impact. Innovations such as the use of recycled polyester fibers not only contribute to sustainability efforts but also maintain the performance characteristics required for industrial applications. This shift towards greener practices reflects a broader trend within industries to adopt more responsible and sustainable operational methods.

As industries continue to face challenges related to efficiency, safety, and environmental impact, the role of polyester conveyor belt fabric technology will undoubtedly expand. The ongoing innovations in weaving techniques, high-performance coatings, smart technology integration, and sustainable practices are setting new standards for conveyor systems. These advancements not only enhance the functionality and reliability of conveyor belts but also align with the evolving needs of modern industries. Consequently, as these technologies continue to develop, they will play a pivotal role in shaping the future of industrial operations, ensuring that businesses can meet the demands of an increasingly competitive market while maintaining a commitment to sustainability and efficiency.